Electrode and manufacturing method thereof

A technology of electrodes and conductive agents, applied in the field of electrodes and their preparation, can solve the problems of poor electrochemical stability of electrodes, achieve the effects of improving electrochemical stability, high flexibility, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

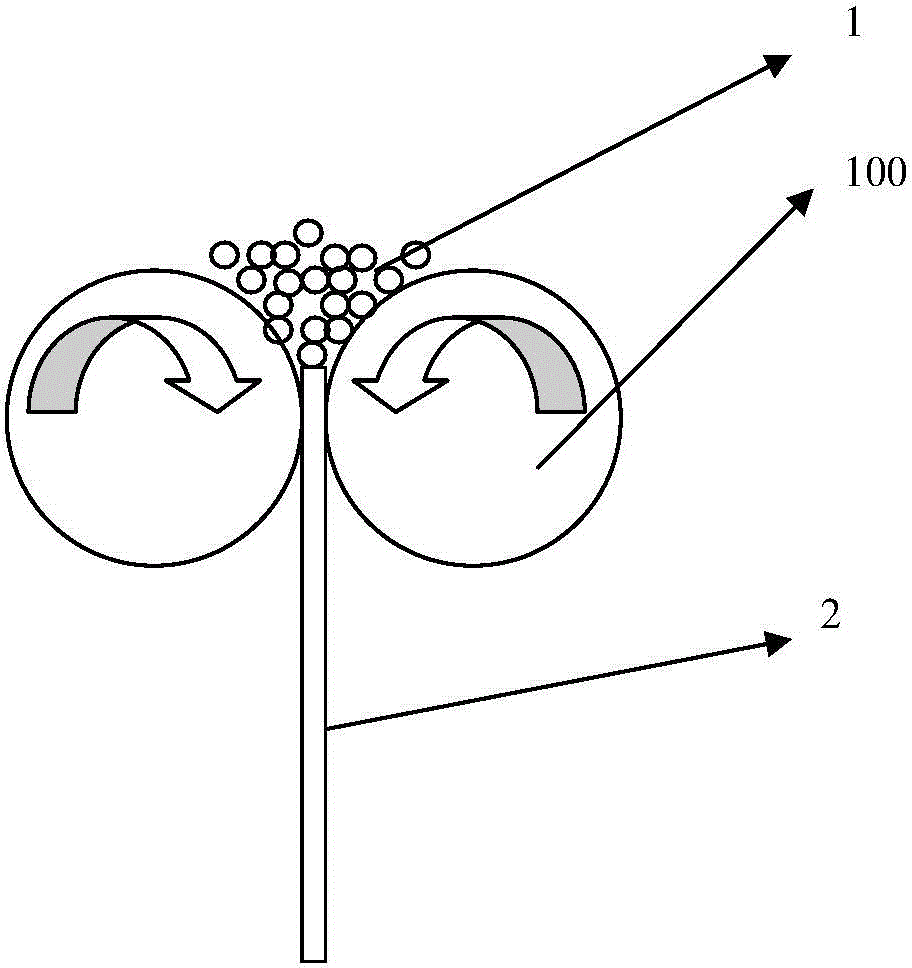

[0042] Another aspect of the present invention provides a preparation method for the above electrode, the preparation method may include:

[0043] Mixing carbon materials, conductive agents, fiber binders, fiber activators and air getters to obtain a mixture;

[0044] Humidify the mixture;

[0045] Kneading the mixed material after the humidification treatment to obtain the kneaded material;

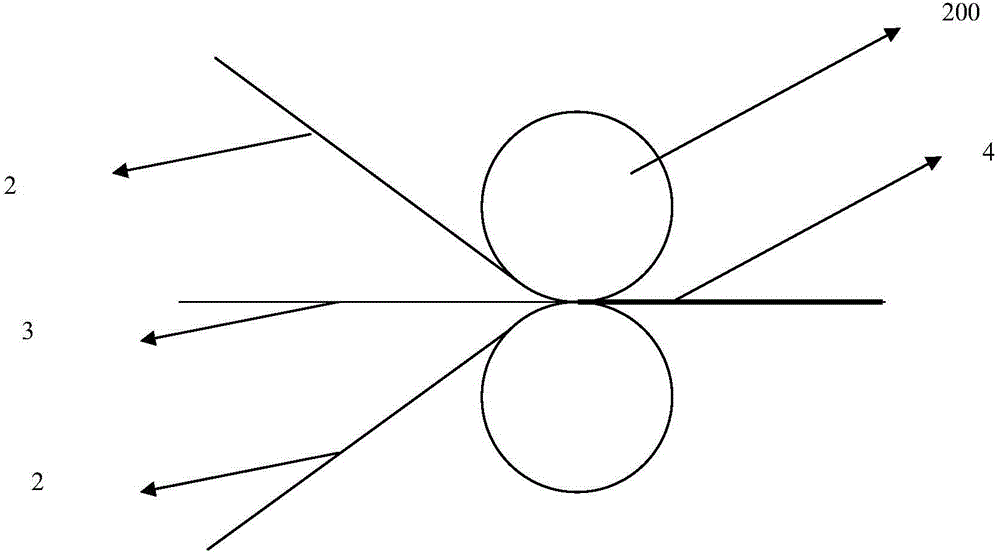

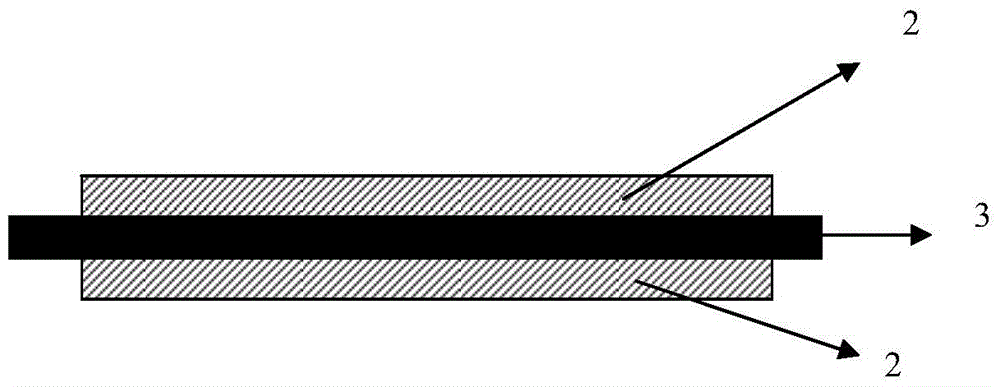

[0046] After the kneaded material is dried and pulverized, it is subjected to molding treatment to obtain a self-supporting film;

[0047] The self-supporting film is thermally laminated with the surface pretreated metal current collector to obtain the electrode.

[0048] Wherein, the mixing can use a V-type mixer or a planetary mixer to mix the above-mentioned materials uniformly.

[0049] The above-mentioned mixing material is carried out humidification treatment, can comprise: adding water and / or C to the mixing material 1–4 alcohol, and stir evenly; among them, the added water and / ...

Embodiment 1

[0065] 1) 8 kg of activated carbon (Kuraray Company, YP50 brand), 1.1 kg of conductive carbon black (Te Mi Gao Company, Superp

[0066] brand), PVDF (polyvinylidene fluoride) 0.5kg (Solvay, solef 5130 brand), fiber activator

[0067] 0.3kg (Total Corporation, 25110 grade), air getter 0.1kg (Saith Corporation, SuiSorb grade) added to

[0068] In a planetary mixer, mix for 30 minutes to obtain a mixture.

[0069] 2) Add 7kg of deionized water to the mixture, and stir evenly for 1 hour.

[0070] 3) Add 0.5kg of isopropanol to the mixture, continue to stir for 30 minutes, the mixture becomes dough, keep stirring for 1 hour at this time, fully knead the mixture, fiberize the fiber binder, and obtain the kneaded mixture.

[0071] 4) Put the kneaded material into a drying oven at 120° C. for 3 hours to remove moisture and isopropanol.

[0072] 5) Put the dried kneaded material into a ball mill and pulverize it to obtain Kneaded Material 1 with a particle size of 12 μm.

[0073] 6...

Embodiment 2

[0077] 1) 7kg of activated carbon (among them, 3.5kg of active carbon of YP50 brand from Kuraray Company, 3.5kg of activated carbon of CEP21KS brand from PCT Company), 0.7kg of carbon nanotubes (Tiannai Company, LB200 brand), PVDF (poly Vinylidene fluoride) 1.6kg (Solvay company, solef 5130 brand), fiber activator 0.3kg (Total company, 25110 brand), air getter 0.1kg (Saisi company, SuiSorb brand) were added in the planetary mixer, mixed After 30 minutes, a mixture was obtained.

[0078] 2) Add 5kg of deionized water to the mixture, and stir evenly for 1 hour.

[0079] 3) Add 0.3kg of isopropanol to the mixture, continue to stir for 30 minutes, the mixture becomes dough, keep stirring for 1 hour at this time, fully knead the mixture, fiberize the fiber binder, and obtain the kneaded mixture.

[0080] 4) Put the kneaded material into a drying oven at 100° C. for 5 hours to remove moisture and isopropanol.

[0081] 5) The dried kneaded material was pulverized in a ball mill to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com