Soybean weeding microemulsion and preparation method thereof

A technology of microemulsion and soybean, which is applied in the direction of herbicides and algicides, botanical equipment and methods, biocides, etc., can solve the problems of weed damage to soybeans, poor removal effect, incomplete removal, etc. Environmental protection and pollution-free, simple production process, strong killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

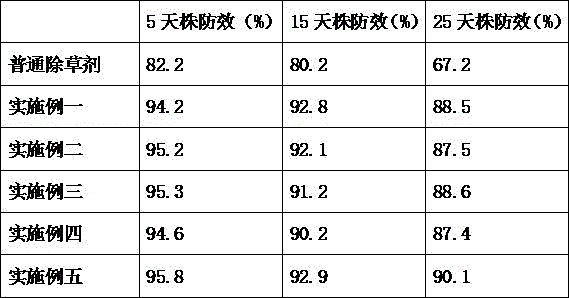

Examples

Embodiment 1

[0016] The proportion of ingredients used is: 10 parts of glyphosate isopropylamine saline solution, 10 parts of sulfentrazone, 10 parts of emulsifier diisooctyl sulfonate sodium succinate, 7 parts of glycerol, and 7 parts of imidazoquinolinic acid 10 parts, 10 parts of surfactant, 5 parts of fulvic acid, 10 parts of chitin, 10 parts of beta-haloxyfop, 5 parts of antifoaming agent and 1 part of preservative.

[0017] The preparation method of the present embodiment comprises the following steps:

[0018] A. Mix glyphosate isopropylamine saline solution, sulfentrazone, and emulsifier diisooctyl sulfonate sodium succinate and stir at room temperature for 10 minutes to obtain A mixture;

[0019] B. Add imidazoquinolinic acid, surfactant, and fulvic acid to the A mixture, stir evenly, pour it into the reaction kettle for heating reaction, the heating temperature is 50°C, and the heating time is 10 minutes, and then stand still to obtain the B mixture agent;

[0020] C. Add chiti...

Embodiment 2

[0023] The proportion of ingredients used is: 12 parts of glyphosate isopropylamine saline solution, 12 parts of sulfentrazone, 12 parts of emulsifier diisooctyl sulfonate sodium succinate, 8 parts of glycerol, and 8 parts of imidazoquinolinic acid 12 parts, 12 parts of surfactant, 6 parts of fulvic acid, 12 parts of chitin, 11 parts of high-efficiency haloxyfop, 6 parts of antifoaming agent and 1 part of preservative; the surfactant is composed of polyoxyalkylene sorbitan ester And heavy alkyl benzene sulfonate mixture.

[0024] The preparation method of the present embodiment comprises the following steps:

[0025] A. Mix glyphosate isopropylamine saline solution, sulfentrazone, and emulsifier diisooctyl sulfonate sodium succinate and stir at room temperature for 10 minutes to obtain A mixture;

[0026] B. Add imidazoquinolinic acid, surfactant, and fulvic acid to the A mixture, stir evenly, pour it into the reaction kettle for heating reaction, the heating temperature is 5...

Embodiment 3

[0030] The proportion of ingredients used is: 30 parts of glyphosate isopropylamine saline solution, 20 parts of sulfentrazone, 20 parts of emulsifier diisooctyl sulfonate sodium succinate, 12 parts of glycerol, 15 parts of imidazoquinic acid parts, 20 parts of surfactants, 12 parts of fulvic acid, 15 parts of chitin, 15 parts of high-efficiency haloxyfop, 10 parts of antifoaming agents and 3 parts of preservatives; the surfactant is composed of polyoxyalkylene sorbitan ester And heavy alkyl benzene sulfonate mixture.

[0031] The preparation method of the present embodiment comprises the following steps:

[0032] A. Mix glyphosate isopropylamine saline solution, sulfentrazone, and emulsifier diisooctyl sulfonate sodium succinate and stir at room temperature for 10 minutes to obtain A mixture;

[0033] B. Add imidazoquinolinic acid, surfactant, and fulvic acid to the A mixture, stir evenly, pour it into the reaction kettle for heating reaction, the heating temperature is 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com