Lutein ester compressed candy and preparation method thereof

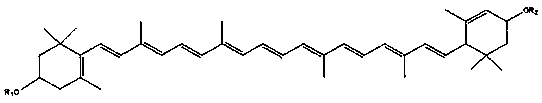

A technology of lutein ester and tableting candy, applied in confectionery, confectionery industry, cocoa and other directions, can solve the problems of poor storage stability, difficult preservation of lutein, poor stability, etc., to improve eyesight and relieve visual fatigue , the effect of sweet and sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

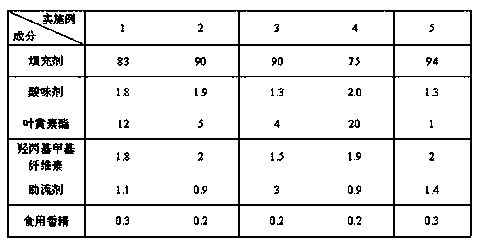

Examples

Embodiment 1

[0034] Preparation:

[0035] (1) Weighing: Weigh 43 parts of sorbitol, 40 parts of mannitol, 1.8 parts of citric acid, 12 parts of lutein ester, 1.8 parts of hydroxypropyl methylcellulose, 1.1 parts of micronized silica gel and edible 0.3 parts of essence, for later use;

[0036] (2) Adsorption: Dissolve citric acid in ethanol aqueous solution with 85% ethanol volume percentage, add micropowder silica gel, stir, carry out hydrogen bond adsorption, evaporate ethanol, dry at 50°C for 2 hours to 4.5% moisture, and obtain Micropowder silica gel with sour taste, use this micropowder silica gel as a flow aid;

[0037] (3) Crush and sieve: crush sorbitol and mannitol, pass through a 65-mesh sieve, then pass the lutein ester through a 65-mesh sieve; pour the sieved sorbitol powder and mannitol powder into the powder mixer , mix the powder for 30 minutes, use ethanol aqueous solution with a volume percentage of 75% ethanol as a wetting agent, and granulate with a 50-mesh sieve; place...

Embodiment 2

[0041] Preparation:

[0042] (1) Weighing: Weigh 90 parts of sorbitol, 1.2 parts of citric acid, 0.7 parts of malic acid, 5 parts of lutein ester, 2 parts of hydroxypropyl methylcellulose, 0.9 parts of micronized silica gel and 0.2 parts of food flavor copy, spare;

[0043] (2) Adsorption: Dissolve citric acid and malic acid in an appropriate amount of ethanol aqueous solution with a volume percentage of 90%, add micropowdered silica gel, hydrogen bond adsorption, evaporate ethanol, dry until the water content is less than 5%, and obtain Sour micropowder silica gel, use this micropowder silica gel as a flow aid;

[0044] (3) Crushing and sieving: crush the sorbitol, pass through a 65-mesh sieve, and then pass the lutein ester through a 65-mesh sieve;

[0045] (4) Tablet compression: mix sorbitol with lutein ester, hydroxypropyl methylcellulose, glidant, food flavor for 30 minutes, and then compress into tablets.

[0046] (5) Packaging: packing the tableted candy to obtain the...

Embodiment 3

[0048] Preparation:

[0049] (1) Weighing: Weigh 40 parts of sorbitol, 50 parts of lactose, 1.3 parts of citric acid, 4 parts of lutein ester, 1.5 parts of hydroxypropyl methylcellulose, 1 part of magnesium stearate, and micronized silica gel 2 parts and 0.2 part of food flavor, for later use;

[0050] (2) Adsorption: Dissolve citric acid in an appropriate amount of ethanol with a volume percentage of 65% ethanol aqueous solution, add micropowdered silica gel, hydrogen bond adsorption, evaporate ethanol, dry until the water content is less than 5%, and obtain a sour powder Silicone gel mixed with magnesium stearate as a glidant;

[0051] (3) Crush and sieve: dry and crush the sorbitol and lactose, pass through a 65-mesh sieve, and then pass the lutein ester through a 65-mesh sieve;

[0052] (4) Tablet compression: Mix sorbitol, lactose, lutein ester, hydroxypropyl methylcellulose, glidants, and food flavors for 30 minutes, and then compress into tablets.

[0053] (5) Packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com