Method for preparing carbon foam adsorbents modified by phenylboronic acid type metal organic framework materials

A metal-organic framework and phenylboronic acid-based technology, applied in organic chemistry, chemical instruments and methods, and other chemical processes, can solve problems such as poor selectivity, low reuse rate, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

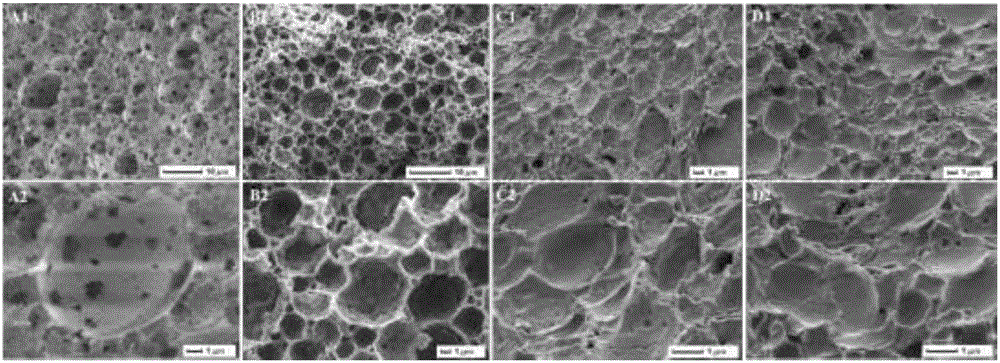

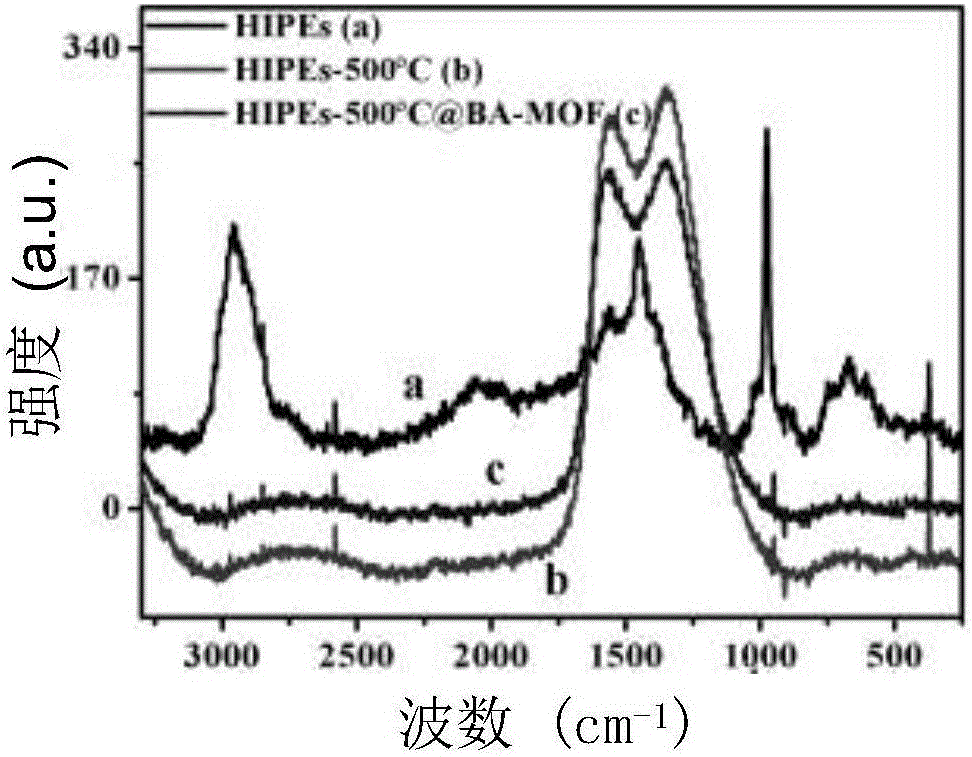

[0032] (1) Preparation of carbon foam (CF)

[0033] Mix 3mL formaldehyde solution and 1.5mL melamine, then add 2g triethanolamine, then vigorously stir at 50°C and 500rpm for 20min, and then obtain a prepolymer solution. Then 6 mL of toluene solution was gradually added dropwise to the pre-poly solution, and then stirred at 1000 rpm for 2 min. The resulting emulsion was then polymerized at 60°C for 3 hours. Then dry it under vacuum at 50°C for 12 hours. 50 mg of the obtained high internal phase emulsion were fired in a tube furnace for 2 hours, and heated to 400, 500, and 600 degrees at 5°C / min to obtain CF-400, CF-500, and CF-600.

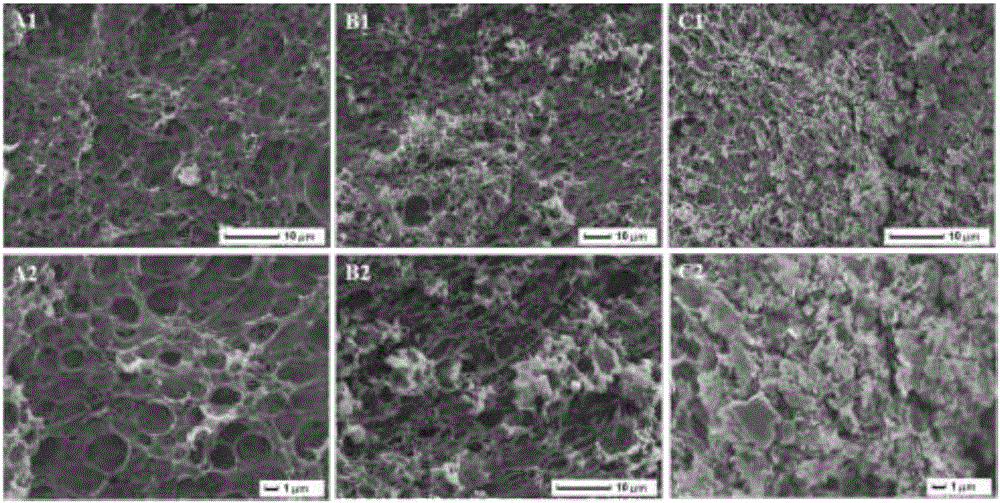

[0034] (2) Preparation of CF-500-B-MOF

[0035] First, put 50mg of CF-500 into 0.1g of zinc nitrate hexahydrate solution, and stir a mixed solution (v:v, 1:1) of 5mL of ethanol and water for 6 hours in a polytetrafluoroethylene reactor . Then add 40 mg of 3,5-dicarboxyphenylboronic acid (BBDC) and 40 mg of terephthalic acid (H 2 BDC) was rea...

Embodiment 2

[0037] (1) Preparation of carbon foam (CF)

[0038] 4mL of formaldehyde solution and 2mL of melamine were mixed, then 3g of triethanolamine was added, and then vigorously stirred at 500rpm at 70°C for 40min to obtain a prepolymer solution. Then gradually add 10 mL of toluene solution dropwise to the pre-poly solution, and then stir at 1000 rpm for 2 min. The resulting emulsion was then polymerized at 80°C for 5 hours. Then dry it under vacuum at 70 degrees for 48 hours. 50 mg of the obtained high internal phase emulsion were fired in a tube furnace for 2 hours, and heated to 400, 500, and 600 degrees at 5°C / min to obtain CF-400, CF-500, and CF-600.

[0039] (2) Preparation of CF-500-B-MOF

[0040] First, put 100mg of CF-500 into 0.2g of zinc nitrate hexahydrate solution and mix it with 15mL of ethanol and water (v:v, 1:1) and stir for 24 hours in a polytetrafluoroethylene reactor . Then add 50 mg of 3,5-dicarboxyphenylboronic acid (BBDC) and 50 mg of terephthalic acid (H ...

Embodiment 3

[0042] (1) Preparation of carbon foam (CF)

[0043] Mix 3.5mL formaldehyde solution and 2mL melamine, then add 2.5g triethanolamine, then stir vigorously at 60°C and 500rpm for 30min, and then obtain the prepolymer solution. Then 8 mL of toluene solution was gradually added dropwise into the pre-poly solution, and then stirred at 1000 rpm for 2 min. The resulting emulsion was then polymerized at 70°C for 4 hours. Then dry it under vacuum at 60°C for 24 hours. 50 mg of the obtained high internal phase emulsion were fired in a tube furnace for 2 hours, and heated to 400, 500, and 600 degrees at 5°C / min to obtain CF-400, CF-500, and CF-600.

[0044] (2) Preparation of CF-500-B-MOF

[0045] First, put 75mg of CF-500 into 0.15g of zinc nitrate hexahydrate solution and stir for 12 hours in a mixed solution (v:v, 1:1) composed of 10mL of ethanol and water in a polytetrafluoroethylene reactor . Then add 45 mg of 3,5-dicarboxyphenylboronic acid (BBDC) and 45 mg of terephthalic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com