N-alkene isomerization catalyst, method for preparing same and application of n-alkene isomerization catalyst

A technology for olefin isomerization and catalysts, which is applied in the field of normal olefin isomerization catalysts and its preparation, can solve problems such as high cost, performance degradation, and easy performance degradation, and achieves maintenance of yield, reduction of quantity, and reduction of other side effects The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

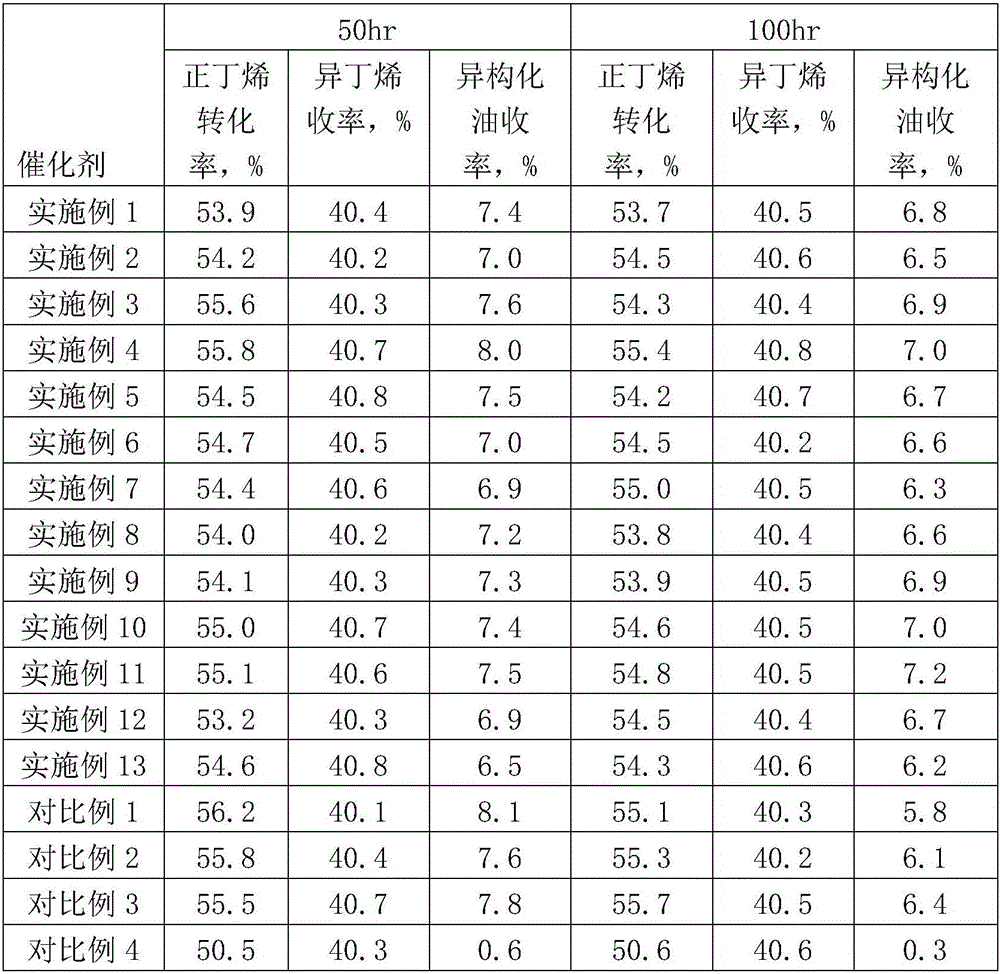

Embodiment 1

[0026] Use crystallized SAPO-11 molecular sieve raw powder and crystallized ZSM-5 molecular sieve raw material as raw materials; SAPO-11 molecular sieve raw powder is easy to disperse to an average particle size of 1.2um, crystallinity 95%, chemical composition P 2 o 5 41%, SiO 2 12%, Al 2 o 3 47% (mass); ZSM-5 molecular sieve raw powder is easily dispersed to an average particle size of 1.6um, a silicon-aluminum ratio of 70, and a crystallinity of 95%. Catalysts were prepared as follows:

[0027] A. Add 2.0kg of SAPO-11 molecular sieve raw powder, 0.5kg of ZSM-5 molecular sieve raw powder and 3.75kg of pseudo-boehmite dry powder into the 20L mixing tank, and mix well;

[0028] C. Take 5.0kg of the mixed powder and transfer it to a kneader, add 0.15kg of scallop powder and mix evenly, add 4.5kg of an aqueous solution containing 0.20kg of acetic acid and knead, extrude with a Φ2.0mm orifice plate, and then dry at 120°C for 6hr, 480 ℃ roasting for 3hr to obtain a catalyst...

Embodiment 2

[0032] Basically the same as Example 1, the difference is that in step A, the amount of SAPO-11 molecular sieve raw powder added is 2.125 kg, and the added amount of ZSM-5 molecular sieve raw powder is 0.375 kg.

[0033] Calculated from the feed ratio, the catalyst prepared in this example contains 50% (mass) of molecular sieves and 50% (mass) of alumina; SAPO-11 accounts for 85% (mass) of molecular sieves, and ZSM-5 accounts for 85% (mass) of molecular sieves. 15% (mass) of the total amount. Judging from the electron micrographs (SEM) of the surface and section of the catalyst, the particle size of the molecular sieve in the catalyst is 1-2um.

Embodiment 3

[0035] Basically the same as Example 1, the difference is that in step A, the amount of pseudo-boehmite dry powder added is 1.60kg, and in step C, take 2.5kg of mixed powder and add 0.075kg of scallop powder to mix, add 0.10kg of acetic acid in the aqueous solution 2.3kg.

[0036]Calculated from the feed ratio, the catalyst prepared in this example contains 70% (mass) of molecular sieves and 30% (mass) of alumina; SAPO-11 accounts for 80% (mass) of molecular sieves, and ZSM-5 accounts for 80% (mass) of molecular sieves. 20% of the total (mass). Judging from the electron micrographs (SEM) of the surface and section of the catalyst, the particle size of the molecular sieve in the catalyst is 1-2um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com