Flower-like ferroferric oxide nano-grade material, and preparation method thereof

A technology of ferroferric oxide and nano-materials, which is applied in the direction of iron oxide/iron hydroxide, ferrous iron oxide, etc., which can solve the problem of serious agglomeration, no flower-like structure, and large particle size of ferroferric oxide and other problems, to achieve the effect of good dispersion, low cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The flower-shaped ferroferric oxide nanomaterial of the present invention is prepared by the following process: (1) Weigh 0.045 mol of ferrous sulfate heptahydrate and 0.090 mol of potassium hydroxide solid, respectively, dissolve them in 90 mL of deionized water, and mix them in hydrogen. Add 0.45mmol of the structure-directing agent polyvinylpyrrolidone to the potassium oxide solution; (2) Under stirring conditions, add the potassium hydroxide solution with the structure-directing agent to the ferrous ion solution to form a dark green colloid, and then add it dropwise 10mL of sodium nitrate solution containing 0.015mol, stirring for 40 minutes; (3) Heat the reacted solution in a water bath at 90°C for 100 minutes, filter the solution after cooling, and dry it in a drying oven at 60°C for 10 hours (4) Magnetic separation of the dried product to obtain flower-like ferroferric oxide nanomaterials.

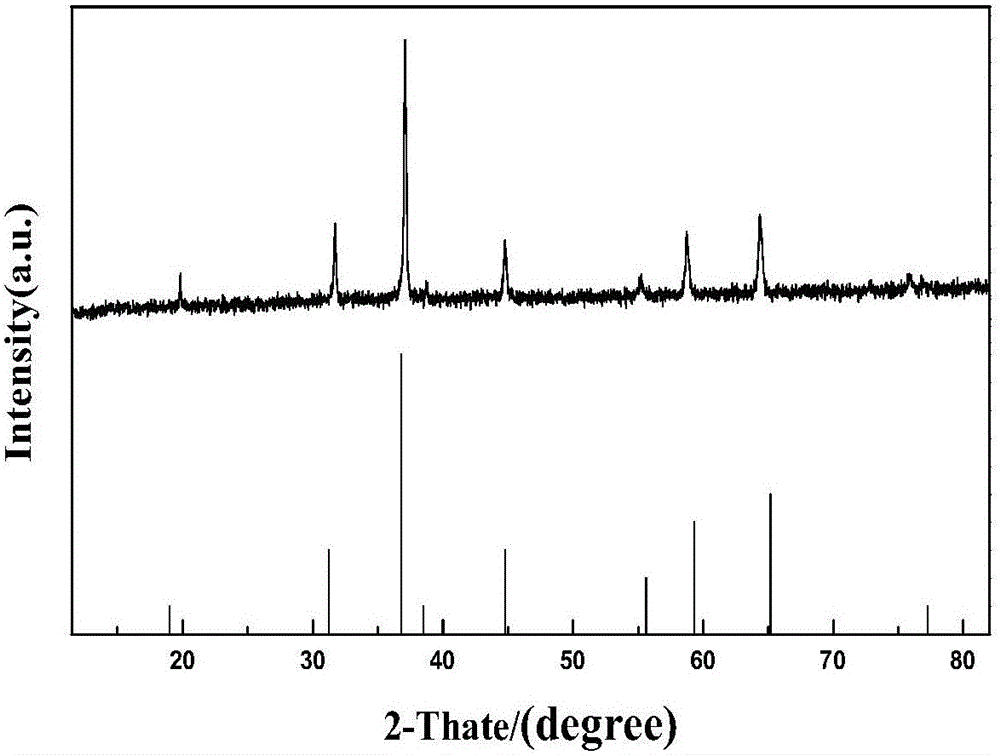

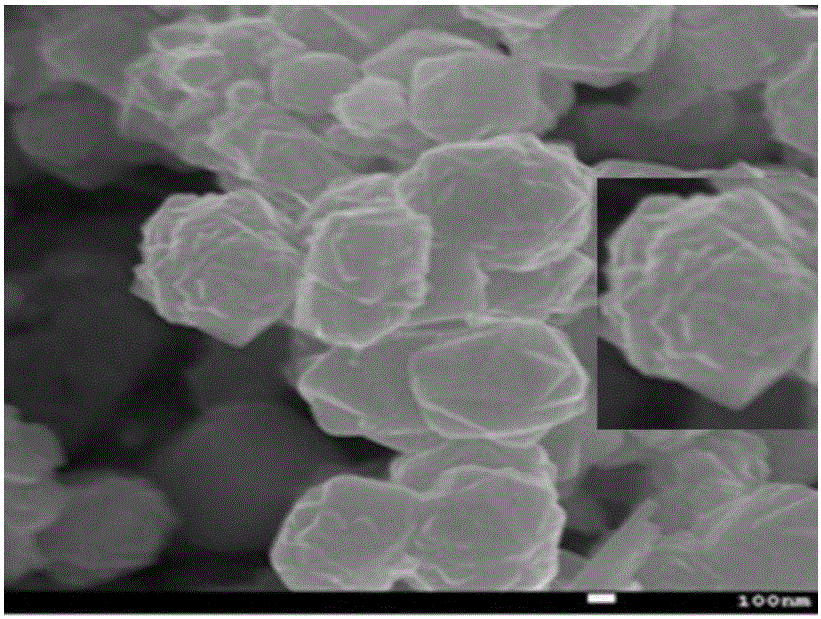

[0029] figure 1 It is the X-ray diffraction (XRD) pattern of the flower-sha...

Embodiment 2

[0034] The flower-shaped ferroferric oxide nanomaterial of the present invention is prepared by the following process: (1) Weigh 0.054 mol of ferrous sulfate heptahydrate and 0.108 mol of potassium hydroxide solid, respectively, and dissolve them in 90 mL of deionized water. Add 0.045mmol of the structure-directing agent polyvinylpyrrolidone to the potassium oxide solution; (2) Under stirring conditions, add the potassium hydroxide solution with the structure-directing agent to the ferrous ion solution to form a dark green colloid, and then add dropwise 10mL of 0.018mol sodium nitrate solution, stirring for 45 minutes; (3) Heat the reacted solution in a water bath at 85°C for 120 minutes, filter the solution after cooling, and dry for 9 hours in a drying oven at 65°C (4) Magnetic separation of the dried product to obtain flower-like ferroferric oxide nanomaterials.

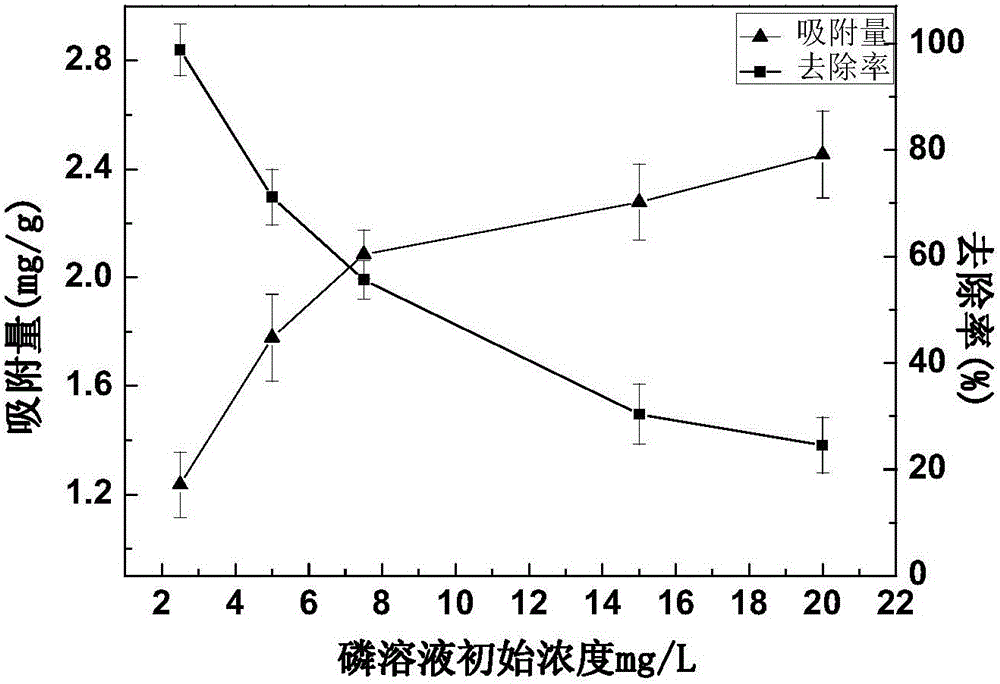

[0035] The prepared flower-shaped ferroferric oxide was subjected to a metal cadmium (Ⅱ) ion adsorption experiment...

Embodiment 3

[0037] The flower-shaped ferroferric oxide nano material of the present invention is prepared by the following process: (1) Weigh 0.0585 mol of ferrous sulfate heptahydrate and 0.117 mol of potassium hydroxide solid, respectively, and dissolve them in 90 mL of deionized water. Add 0.050mmol of the structure-directing agent polyvinylpyrrolidone to the potassium oxide solution; (2) Under stirring conditions, add the potassium hydroxide solution with the structure-directing agent to the ferrous ion solution to form a dark green colloid, and then add dropwise 10mL of sodium nitrate solution containing 0.0195mol, stirring for 50 minutes; (3) Heat the reacted solution in a water bath at 80°C for 140 minutes, filter the solution after cooling, and dry it in a drying box at 70°C for 8 hours (4) Magnetic separation of the dried product to obtain flower-like ferroferric oxide nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com