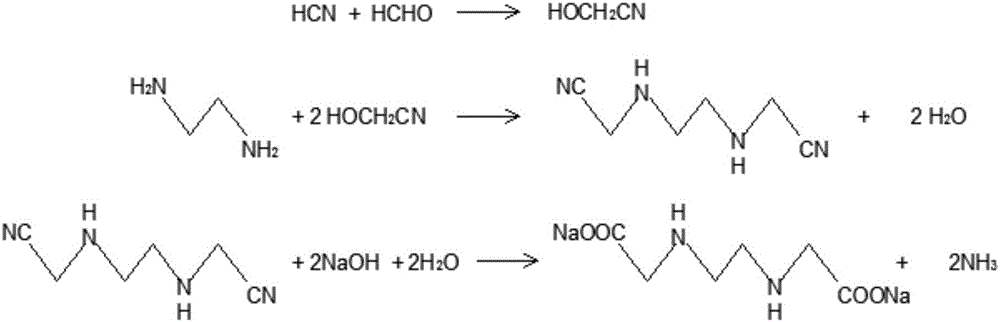

Process for synthesizing ethylenediamine-N-N'-disodium oxalic acid

A technology of disodium acetate and synthesis process, which is applied in the preparation of carboxylic acid nitrile, the preparation of organic compounds, organic chemistry, etc., can solve the problems of low purity, unsuitability for large-scale industrial production, and environmental protection, and achieve a simple reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The detection method used in embodiment and comparative example:

[0021] Product liquid detection method: refer to GB / T1401-1998.

[0022] The reagent used in embodiment and comparative example:

[0023] Ethylenediamine: analytically pure, with a content greater than 99%; formaldehyde solution: analytically pure, with a mass concentration of 36.5%; hydrocyanic acid: industrial grade, with a content greater than 99%; NaOH: industrial grade, with a mass concentration of 30.5%

[0024] Example 1

[0025] Put 140.59g of formaldehyde into the four-neck bottle, add 47.81g of hydrocyanic acid dropwise at 5-10°C, and keep warm for 1 hour after the dropwise addition to obtain a hydroxyacetonitrile solution; In the ethylenediamine, the dropping temperature is 25-30°C, and after the dropping is completed, the temperature is kept for 3 hours to obtain the intermediate product EDDN aqueous solution with a content of 49.6%.

[0026] After mixing the intermediate product EDDN aque...

Embodiment 2

[0027] Embodiment 2 (ethylenediamine: formaldehyde: HCN=1:2.00:2.00)

[0028] Put 141.18g of formaldehyde into the four-neck bottle, add 46.38g of hydrocyanic acid dropwise at 10-15°C, and keep warm for 2 hours after the dropwise addition to obtain a hydroxyacetonitrile solution; In the ethylenediamine, the dropwise addition temperature is 25-30° C., and after the dropwise addition is completed, the temperature is kept for 4 hours to obtain an intermediate product EDDN aqueous solution with a content of 48.5%.

[0029] After mixing the intermediate product EDDN aqueous solution obtained in the previous step with liquid caustic soda, first raise the temperature to 60°C for 2 hours, then raise the temperature to 110-115°C for alkaline hydrolysis, reflux for 2 hours, and remove the ammonia gas generated by the reaction at the same time to obtain EDDA-2Na liquid products. The liquid product of EDDA-2Na is dehydrated to 100°C under normal pressure, and then dried at 100-150°C to o...

Embodiment 3

[0030] Embodiment 3 (ethylenediamine: formaldehyde: HCN=1:1.95:1.95)

[0031] Put 133.64g of formaldehyde into the four-neck bottle, add 43.91g of hydrocyanic acid dropwise at 10-16°C, and keep warm for 3 hours after the dropwise addition to obtain a hydroxyacetonitrile solution; In the ethylenediamine, the dropwise addition temperature is 20-25°C, and after the dropwise addition is completed, the temperature is kept for 5 hours to obtain an intermediate product EDDN aqueous solution with a content of 47.5%.

[0032] After mixing the intermediate product EDDN aqueous solution obtained in the previous step with liquid caustic soda, first raise the temperature to 60°C for 2 hours, then raise the temperature to 110-115°C for alkaline hydrolysis, reflux for 2 hours, and remove the ammonia gas generated by the reaction at the same time to obtain EDDA-2Na liquid products. The liquid product of EDDA-2Na is dehydrated to 100°C under normal pressure, and then dried at 100-150°C to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com