Diatomite modified by polyaryletherketone containing boric m-benzene and reinforced polyether-ether-ketone composite material thereof

A technology of phenylene polyarylether ketone and phenylene polyarylether ketone coupling agent, which is applied in the field of polymer composite materials, and can solve the problems that the modification effect cannot be achieved, and the coupling agent is easy to decompose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

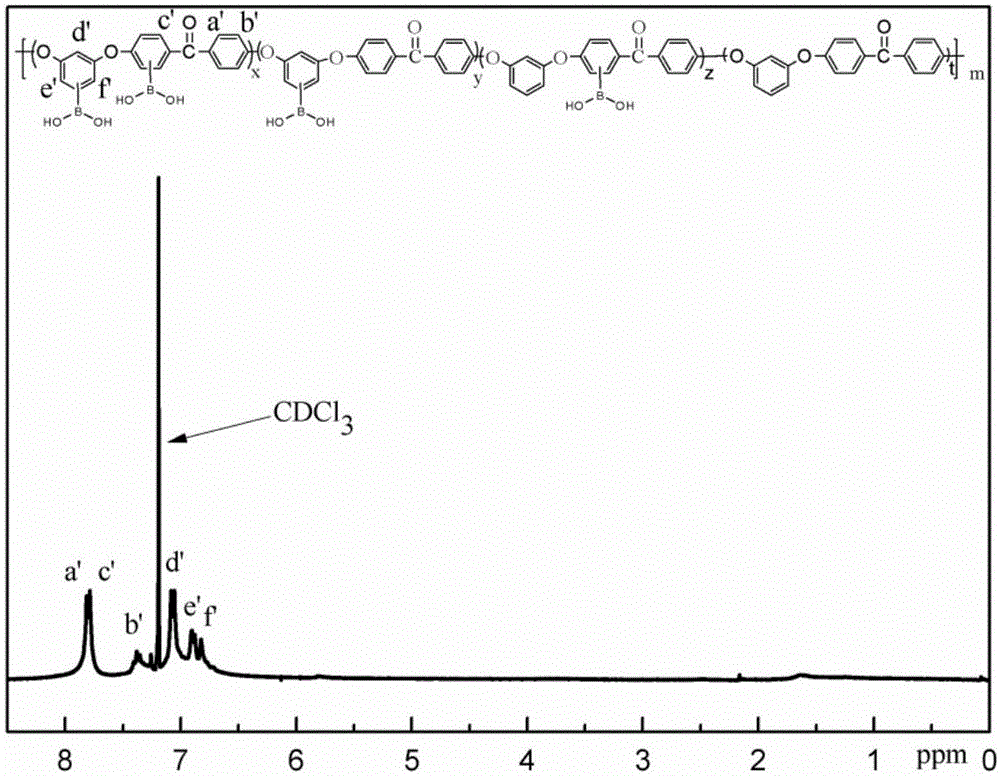

[0029] Example 1: Preparation of boric acid-containing m-phenylene polyaryletherketone coupling agent modified diatomite

[0030] (1) Taking 4 wt% of boric acid-containing m-phenylene polyarylether ketone as an example, weigh 100g of diatomaceous earth, put it into a 1000mL beaker, add 500mL of distilled water, drop the concentrated sulfuric acid with a mass fraction of 98% with a dropper, adjust The pH value is 2, stirred for 1 hour, and suction filtered; then the suction filtered product is washed 3 times with water and acetone respectively to remove impurities, dried at a constant temperature of 80°C for 8 hours in vacuum, and set aside;

[0031] (2) Weigh 4g of boric acid-containing m-phenylene polyaryletherketone coupling agent, add it into a 1000mL three-necked flask containing a stirrer, add 500mL of chloroform, stir, and wait for it to completely dissolve;

[0032] (3) Weigh 96 g of acid-treated diatomite and add it to the above solution, stir at room temperature for 8 h...

Embodiment 2

[0035] Example 2: Preparation of diatomite-reinforced polyether ether ketone composite material (taking diatomite content as 20wt% and the amount of hydroquinone added in in-situ polymerization as 0.5mol as an example)

[0036] (1) Preparation of diatomite suitable for in-situ polymerization: Weigh 100g of diatomite, put it into a 1000mL beaker, add 500mL of distilled water, drop in concentrated sulfuric acid with a mass fraction of 98% with a dropper, adjust the pH value to 2, Stir for 2 hours, then filter with suction; then wash the filtered product with water and acetone for 3 times, remove impurities therein, dry in vacuum at 80°C for 8 hours, and set aside;

[0037] (2) Weigh 36.12 g of diatomite and 520.32 g of diphenyl sulfone which were treated with dilute sulfuric acid and dried for later use, and then add diphenyl sulfone and diatom earth to the reaction device in turn, vacuumize and pass nitrogen, and then alternately carry out 3 times . The rest of the feeding amo...

Embodiment 3

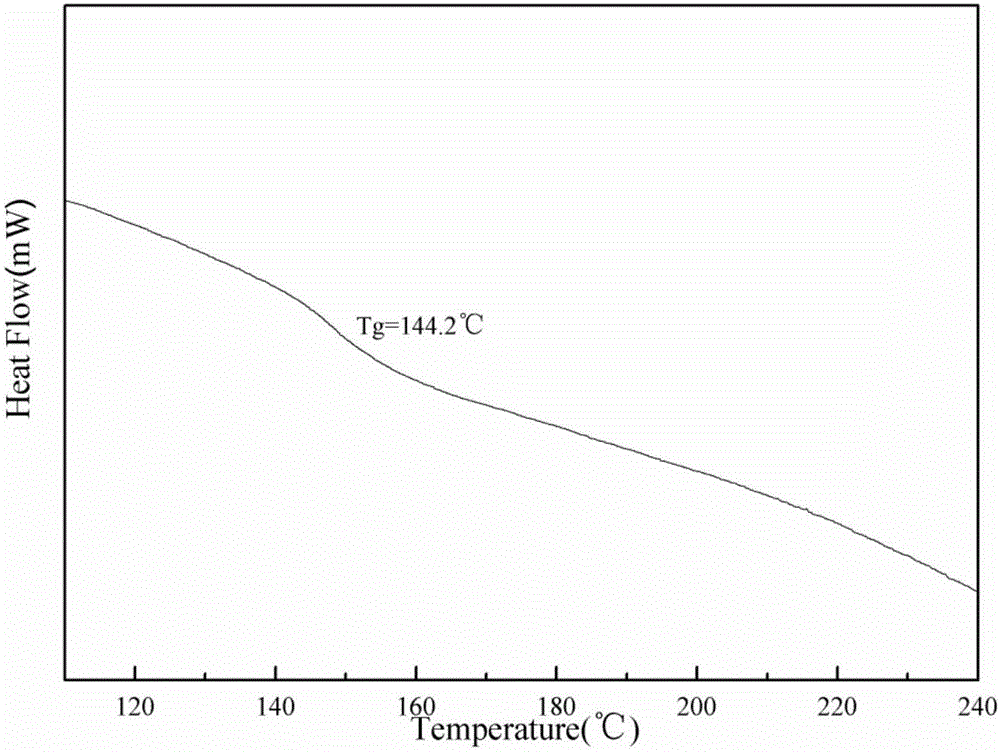

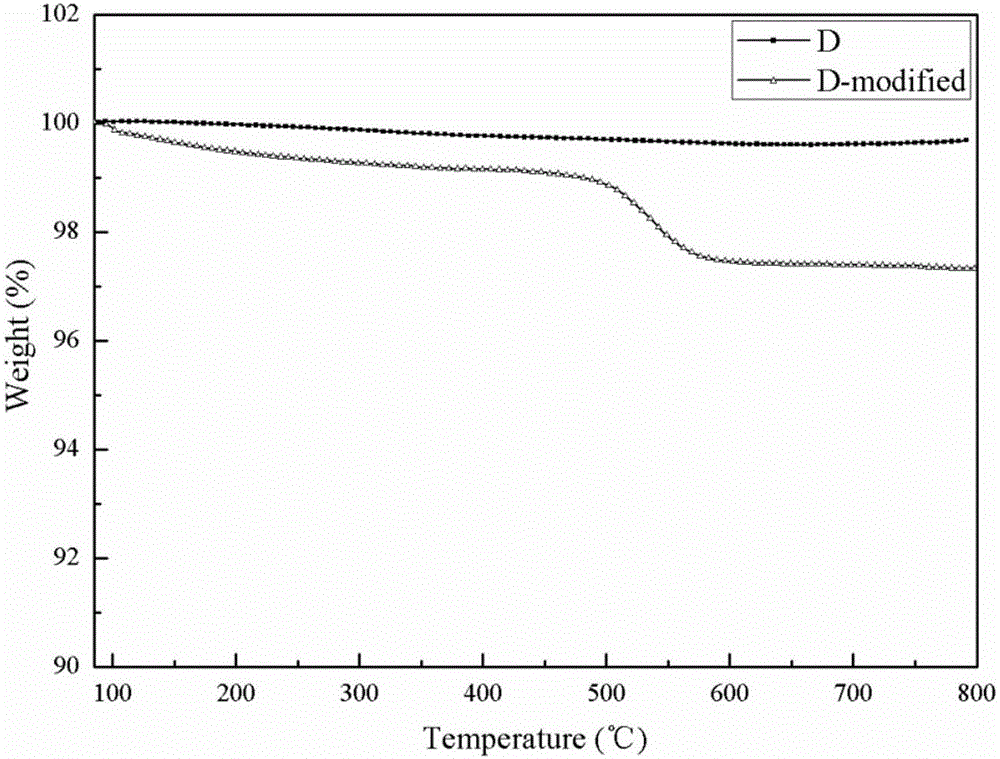

[0039] Example 3: Preparation of boric acid-containing m-phenylene polyaryletherketone modified diatomite reinforced polyetheretherketone composite material, with the content of diatomite modified in Example 1 as 20wt%, adding hydroquinone during polymerization The amount is 0.5mol as an example)

[0040] (1) Weigh 510.32g of diphenyl sulfone, add it to a 3000mL three-necked flask, heat it under nitrogen gas to dissolve it, and then add Na 2 CO 3 56.48g, K 2 CO 3 3.20g, 110.23g (0.505mol) of 4,4'-difluorobenzophenone, 55.06g (0.5mol) of hydroquinone, 150mL of xylene, after the reaction was carried out for 8 hours, after the viscosity of the system increased, add 4 , 1.1g of 4'-difluorobenzophenone was capped and then added 36.63g of boric acid-containing m-phenylene polyaryletherketone coupling agent-modified diatomite prepared in Example 1 (see the patent "a silicon Alite / polyetheretherketone composite material and its preparation method, CN104559048A"), the raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com