Graphene modified and enhanced polyurethane composite material for 3D printing

A graphene modification and composite material technology, applied in the direction of additive processing, etc., can solve the problems of unsatisfactory antibacterial, antifouling and self-cleaning functions, enrichment of pollutants, adverse effects on human health, etc., to increase antibacterial and aldehyde removal. Effects, effects that broaden the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

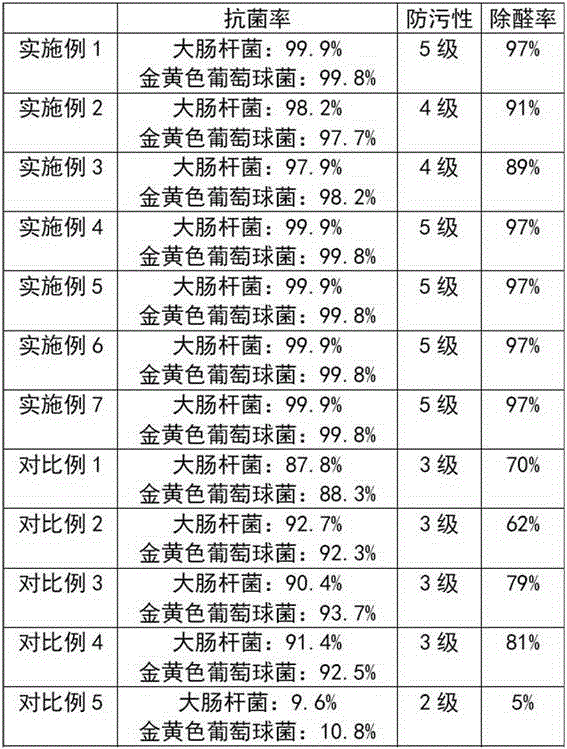

Examples

preparation example Construction

[0018] (4) The preparation method of graphene / calcium carbonate composite filler is as follows: add 1 part of graphene into 100ml deionized water, disperse for 200min under 800kW ultrasonic vibration and 1300r / min centrifugal speed stirring to prepare graphene dispersion; Add a portion of quantum dot calcium carbonate to 500ml of deionized water, and disperse for 300 minutes under 1300kW ultrasonic vibration and 1500r / min centrifugal speed stirring to prepare a calcium carbonate dispersion; slowly drop the calcium carbonate dispersion into the graphene dispersion under 100kW ultrasound , Ultrasonic for 60min, then suction filtration and drying to prepare graphene / calcium carbonate composite filler.

[0019] (5) The nano silver / TiO 2 The preparation method of antibacterial material is as follows: to 200ml 0.01mol·L -1 HNO 3 Add 0.79g AgNO to the solution 3 , 5g TiO 2 Nanotubes, 0.5g dispersant sodium cetyl sulfonate, ultrasonically dispersed for 60 minutes, and then magnetically st...

Embodiment 1

[0024] A graphene modified reinforced polyurethane composite material for 3D printing, which is composed of the following raw materials in parts by weight: 100 parts of polyurethane, 8 parts of composite filler, 2 parts of functional materials, 0.2 parts of light stabilizer, 5 parts of coupling agent, 0.1 part of leveling agent, 3 parts of dispersion lubricant and 0.5 part of antioxidant. The composite filler is composed of graphene / SiO in a weight ratio of 3:2 2 Composite filler and graphene / calcium carbonate composite filler.

[0025] The preparation method of the composite material includes the following steps:

[0026] (1) Pretreatment of polyurethane raw materials: pulverize the polyurethane raw materials into 300 mesh powder, disperse them in pure water, ultrasonic (power 300W) for 1 hour, and irradiate with microwave (2500MHz, temperature controlled at 85°C) while ultrasonic for 1 hour; Stop ultrasonic and microwave irradiation, washing, discharging, and drying to obtain pr...

Embodiment 2

[0032] Based on Example 1, the difference is: 1 part of functional material. The tensile strength of the prepared polyurethane composite material is 24.05MPa, and the Young's modulus is 0.05GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com