Synthetic oil based lubricating oil having high wear resistance

A high anti-wear and lubricating oil technology, applied in the field of lubricating oil, can solve the problems of decreased anti-wear performance and rising freezing point, and achieve the effects of improving extreme pressure performance, improving shape and size, and better pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

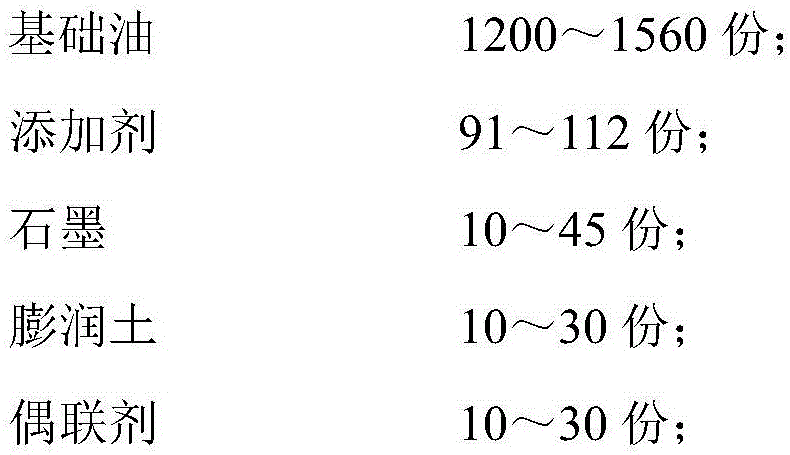

[0016] Synthetic oil-based high anti-wear lubricating oil, its components and content in parts by mass are:

[0017]

[0018]

[0019] The raw materials of the additives include: 45 parts of white oil, 30 parts of fumarate mixture, 10 parts of vinyl acetate, 3 parts of vinylpyrrolidone and 3 parts of diamond nano particles according to the parts by mass.

[0020] Wherein the proportioning of each component in the fumaric acid ester mixture according to the mass fraction is: 5 parts of decyl fumarate, 12 parts of fuma rosin pentaerythritol ester, and 13 parts of dimethyl fumarate.

[0021] Wherein the preparation method of the additive is: 45 parts of white oil are mixed with 5 parts of decyl fumarate, 12 parts of fuma rosin pentaerythritol ester, and 13 parts of dimethyl fumarate, and then add 10 parts of vinyl acetate, 3 parts of vinylpyrrolidone and 3 parts of diamond nanoparticles, slowly raise the temperature to 45°C, stir vigorously for 2 hours, then add 0.1 part of...

Embodiment 2

[0023] Synthetic oil-based high anti-wear lubricating oil, its components and content in parts by mass are:

[0024]

[0025] The raw materials of the additives include: 50 parts of white oil, 40 parts of fumarate mixture, 12 parts of vinyl acetate, 5 parts of vinylpyrrolidone and 5 parts of diamond nano particles according to the parts by mass.

[0026] Wherein the proportioning of each component in the fumaric acid ester mixture according to the mass fraction is: 6 parts of decyl fumarate, 15 parts of fuma rosin pentaerythritol ester, and 19 parts of dimethyl fumarate.

[0027] Wherein the preparation method of the additive is: 50 parts of white oil are mixed with 6 parts of decyl fumarate, 15 parts of fuma rosin pentaerythritol ester, and 19 parts of dimethyl fumarate, and then 12 parts of vinyl acetate are added, 5 parts of vinylpyrrolidone and 5 parts of diamond nanoparticles, slowly raise the temperature to 55°C, stir vigorously for 3 hours, then add 0.2 parts of benz...

Embodiment 3

[0029] Synthetic oil-based high anti-wear lubricating oil, its components and content in parts by mass are:

[0030]

[0031] Wherein the additive raw materials include according to mass parts: 48 parts of white oil, 35 parts of fumarate mixture, 11 parts of vinyl acetate, 4 parts of vinylpyrrolidone and 4 parts of diamond nanoparticles.

[0032] Wherein the proportion of each component in the fumaric acid ester mixture according to the mass fraction is: 6 parts of decyl fumarate, 13 parts of fuma rosin pentaerythritol ester, and 16 parts of dimethyl fumarate.

[0033] Wherein the preparation method of the additive is: 48 parts of white oil are mixed with 6 parts of decyl fumarate, 13 parts of fuma rosin pentaerythritol ester, and 16 parts of dimethyl fumarate, and then add 11 parts of vinyl acetate, 4 parts of vinylpyrrolidone and 4 parts of diamond nanoparticles, slowly raise the temperature to 50°C, stir vigorously for 2 to 3 hours, then add 0.15 parts of benzoyl peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com