Lactobacillus plantarum freeze-dried powder and preparation method thereof

A technology of Lactobacillus plantarum, freeze-dried powder, applied in biochemical equipment and methods, microorganism-based methods, bacteria and other directions, can solve problems such as poor freeze-drying protection effect, achieve good low-temperature preservation effect, and improve freeze-drying survival rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 lyoprotectant

[0026] Weigh a certain quality of WPI, dissolve it completely in a certain amount of purified water, prepare a WPI solution with a concentration of 100g / L-300g / L, and pasteurize it; then weigh a certain quality of inulin and sorbitol, and prepare two The concentrations of both are 80g / L-240g / L solution, sterilized at 115°C for 20 minutes; 40g / L-120g / L sodium ascorbate membrane filter to sterilize. After sterilization, each protective agent solution was mixed in a sterile environment at a volume ratio of 2:1:1 to obtain a freeze-dried protective agent.

Embodiment 2

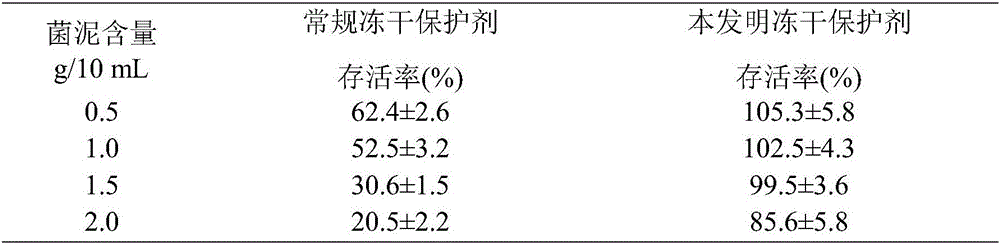

[0027] The preparation of embodiment 2 Lactobacillus plantarum CCFM 8610 freeze-dried bacteria powder

[0028] (1) Composition of lyoprotectant: WPI 60g / L, sorbitol 40g / L, inulin 40g / L, sodium ascorbate 20g / L; conventional lyoprotectant composition: skimmed milk 120g / L, sucrose 20g / L, Trehalose 20g / L.

[0029] (2) Collection of bacterial cells: After the bacterial strains were cultivated to the end of the logarithmic growth phase, they were centrifuged at 8000g, the supernatant was discarded, washed twice with normal saline with pH 7.0, and finally the supernatant was discarded by centrifugation to obtain wet bacterial cells.

[0030] (3) Freeze-drying: take 0.5g, 1.0g, 1.5g, and 2.0g of wet thalline, add 10mL of the protective agent of the present invention and conventional protective agent respectively, after fully mixing, carry out vacuum freeze-drying, the freeze-drying steps are:

[0031] Fully mix the collected Lactobacillus plantarum and the freeze-drying protective ag...

Embodiment 3

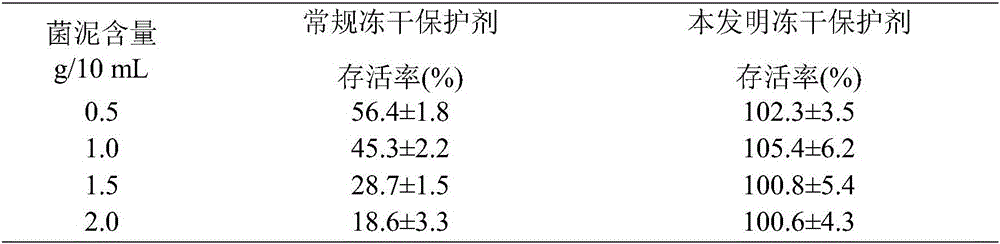

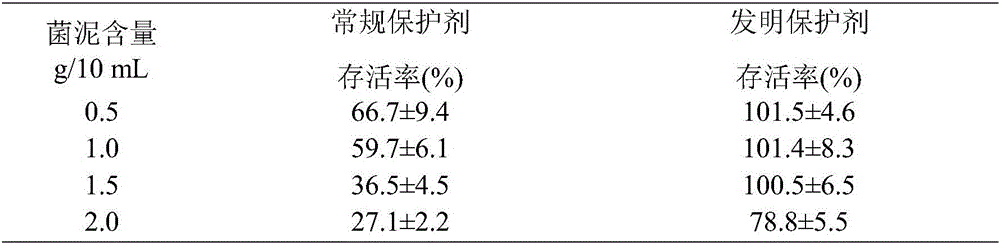

[0051] The preparation of embodiment 3 Lactobacillus plantarum ATCC 14917 freeze-dried bacteria powder

[0052] (1) The lyoprotectant composition of the present invention: WPI 60g / L, sorbitol 40g / L, inulin 40g / L, sodium ascorbate 20g / L; conventional lyoprotectant composition: skimmed milk 120g / L, sucrose 20g / L, trehalose 20g / L.

[0053] (2) After the bacterial strain is cultivated to the end of the logarithmic growth phase, centrifuge at 8000g, discard the supernatant, wash twice with physiological saline with pH 7.0, and finally centrifuge and discard the supernatant to obtain wet cells.

[0054] (3) Freeze-drying: take 0.5g, 1.0g, 1.5g, and 2.0g of wet thalline, add 10mL of the protective agent of the present invention and conventional protective agent respectively, after fully mixing, carry out vacuum freeze-drying, the freeze-drying steps are:

[0055] Fully mix the collected Lactobacillus plantarum and the freeze-drying protective agent solution, pour the bacterial susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com