System and method for measuring effective emissivity of metal solidifying point black body based on radiant quantity measurement

A metal solidification and measurement system technology, applied in the field of optical metrology, can solve the problems that the actual value of the effective emissivity of the blackbody at the solidification point cannot be obtained, and the emissivity of the blackbody at the metal solidification point cannot be detected, etc., achieving high measurement accuracy and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention below in conjunction with specific embodiment:

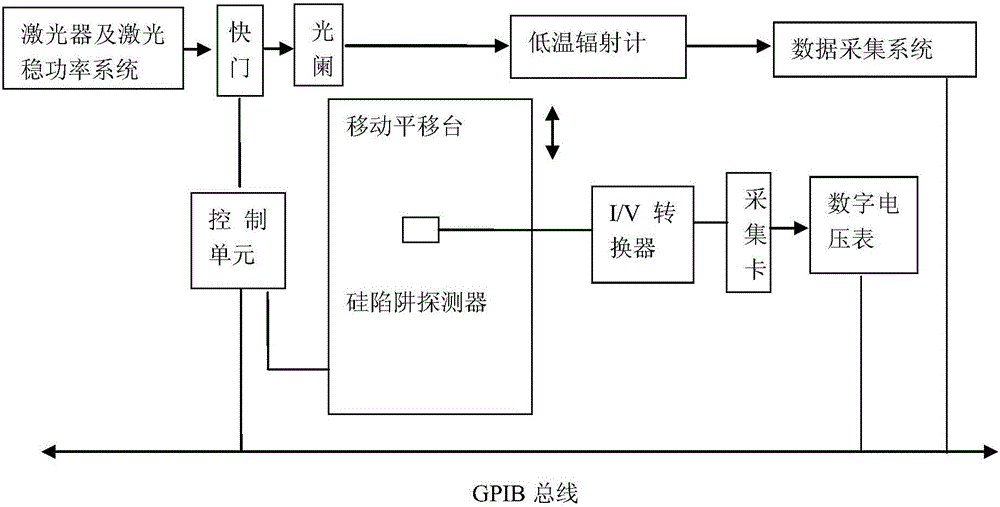

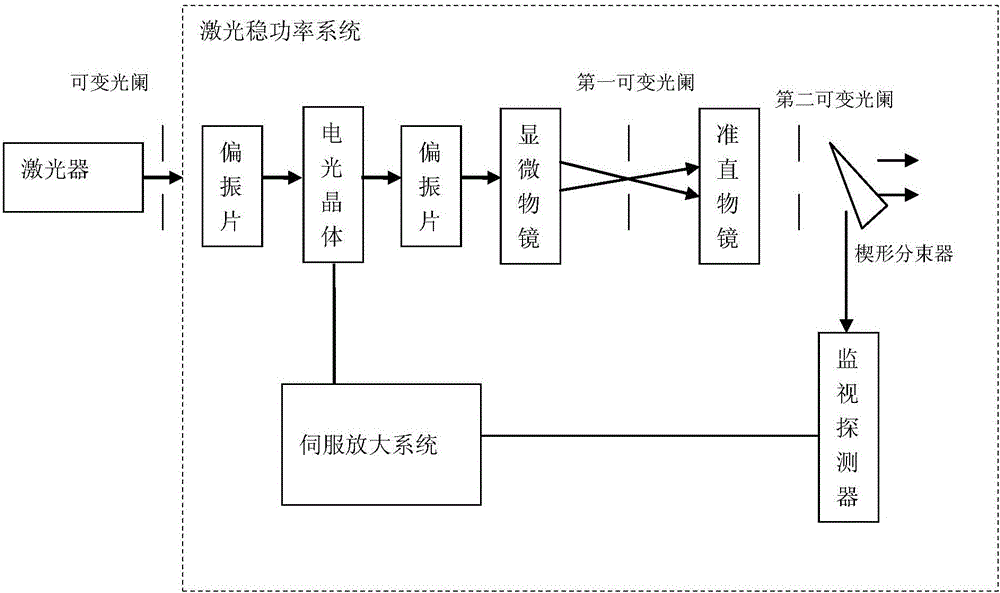

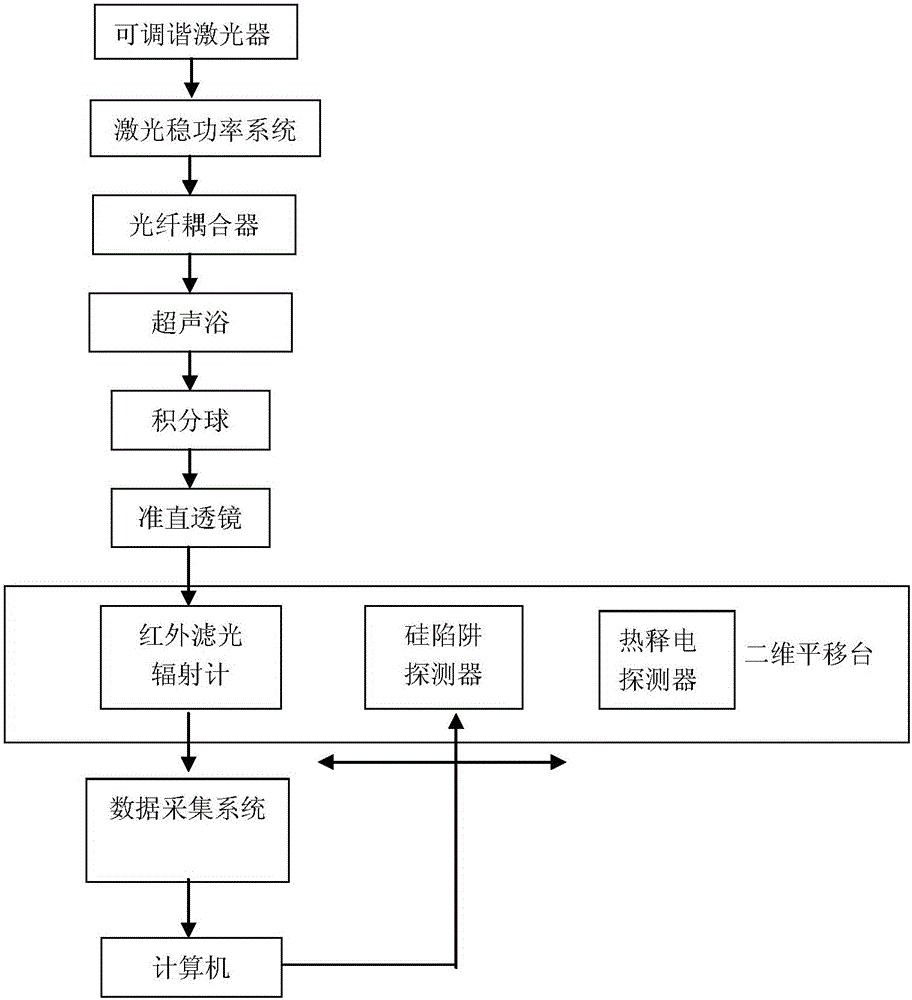

[0022] At present, the emissivity of metal solidification point blackbody cannot be detected, and can only be calculated according to the cavity structure, cavity material and coating material in the cavity. Since the actual value of the effective emissivity of the solidification point blackbody cannot be obtained, the measurement work of blackbody emissivity parameters has a to unpredictable uncertainties. With the development of cryogenic radiometer technology, such as the new generation of CryoRad-Ⅲ cryogenic radiometer system newly developed by NIST in the United States, its response wavelength ranges from 0.2μm-25μm, the receiver responsivity is greater than 2K / mW, and the minimum dynamic range is 1μW-1mW. The uncertainty is less than 0.005%, so that the radiation of the detector can reach the infrared band. Therefore, based on the idea of using a low-temperature radiometer as the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com