A preparation method of lithium titanate/polyaniline composite material with good rate performance

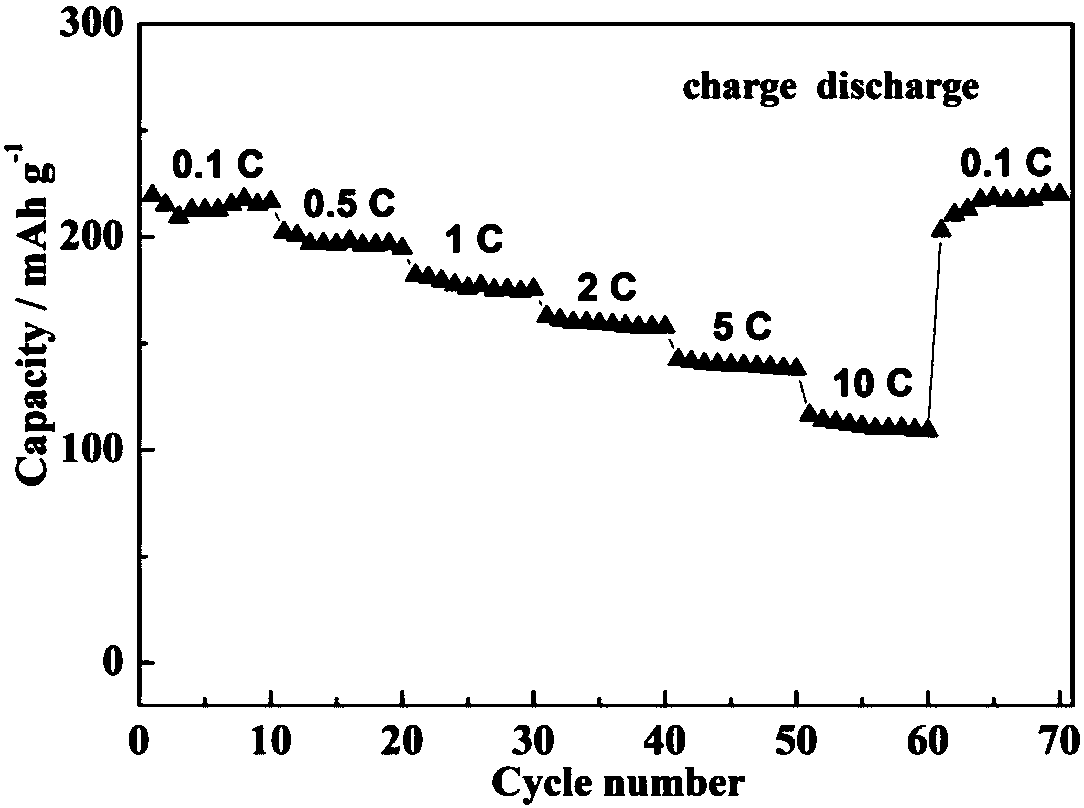

A rate performance, composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of difficult large-scale production, complicated preparation process, etc., achieve good crystallinity, shorten the preparation period, and improve the rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a lithium titanate / polyaniline composite material with good rate performance, comprising the following steps:

[0032] 1) Drop a lithium-containing solution with a lithium ion concentration of 0.2 to 5 mol / L into tetrabutyl titanate, and magnetically stir at 20 to 100°C for 20 to 120 minutes to prepare emulsion A, in which Li The ratio of the amount of substance to Ti is (0.7~1.5):1, wherein the lithium-containing solution is an aqueous solution of lithium carbonate, lithium oxalate, lithium acetate or lithium hydroxide;

[0033] 2) placing the emulsion A in an oven at 70-100°C for 1-48 hours to obtain a solid product B;

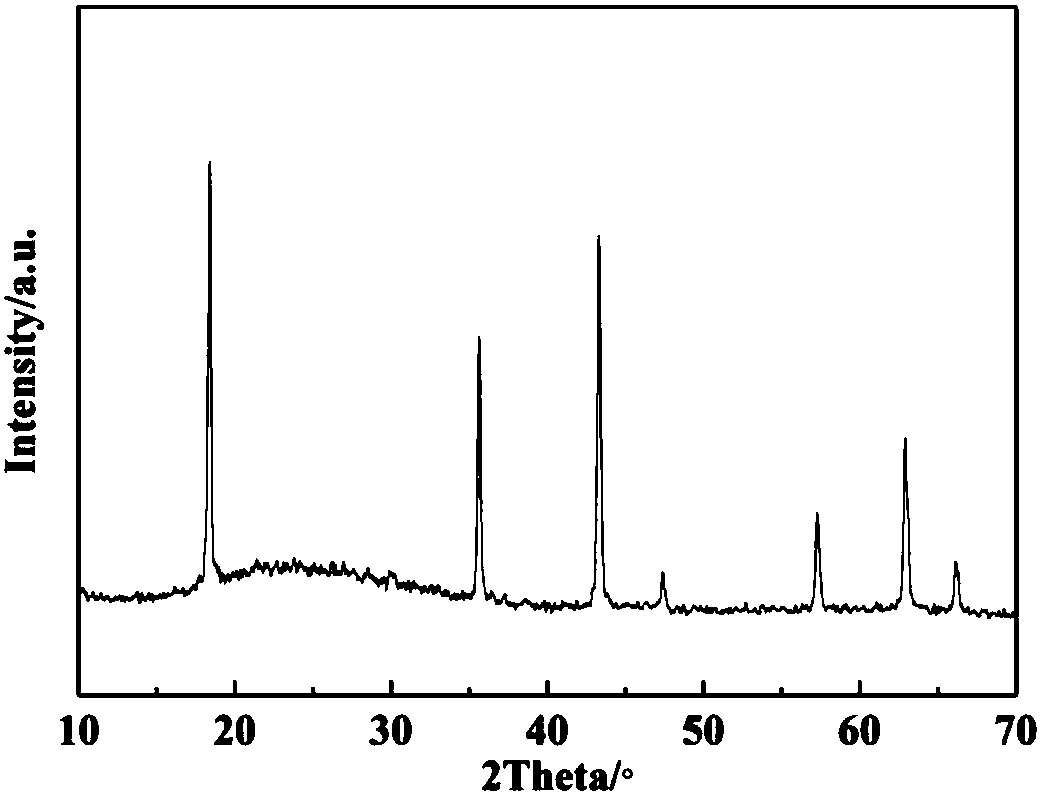

[0034] 3) Grinding the solid product B, placing it in a muffle furnace, raising the temperature to 400-1000°C at a heating rate of 6-10°C / min, keeping it warm for 2-15 hours, and then cooling to room temperature to obtain lithium titanate C;

[0035] 4) Add lithium titanate C to distilled water and ultrasonically disperse for ...

Embodiment 1

[0043] (1) Slowly drop a lithium oxalate solution with a lithium ion concentration of 0.2 mol / L into tetrabutyl titanate, and stir magnetically at 20°C for 120 minutes to prepare emulsion A, in which Li and Ti The ratio of the amount of substance is 0.7:1;

[0044] (2) Put the emulsion A into an oven for reaction, the temperature of the oven is 80° C., and take out the solid product from the oven after 1 hour to obtain the solid product B;

[0045] (3) Grinding the solid product B, placing it in a muffle furnace, raising the temperature to 600°C at a heating rate of 6°C / min for heat treatment for 2 hours, and then cooling to room temperature to obtain lithium titanate C;

[0046] (4) Add lithium titanate C to distilled water and ultrasonically disperse for 1 hour to obtain a lithium titanate aqueous solution, and then add the surfactant cetyltrimethylammonium bromide according to the mass ratio of lithium titanate C:surfactant of 1:0.1 , to obtain a solution D, wherein 1 mol ...

Embodiment 2

[0053] (1) Slowly drop lithium acetate solution with a lithium ion concentration of 1 mol / L into tetrabutyl titanate, and magnetically stir at 100°C for 20 minutes to prepare emulsion A, the substance of Li and Ti in emulsion A The ratio of the quantity is 0.85:1;

[0054] (2) Put the emulsion A into an oven for reaction, the temperature of the oven is 70° C., after 5 hours, the product that has become solid is taken out from the oven to obtain the solid product B;

[0055] (3) Grinding the solid product B, placing it in a muffle furnace, raising the temperature to 1000°C at a heating rate of 10°C / min for heat treatment for 8 hours, and then cooling to room temperature to obtain lithium titanate C;

[0056] (4) Add lithium titanate C to distilled water and ultrasonically disperse for 2 hours to obtain a lithium titanate aqueous solution, and then add the surfactant sodium dodecylbenzenesulfonate according to the mass ratio of lithium titanate C:surfactant of 1:0.15 , to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com