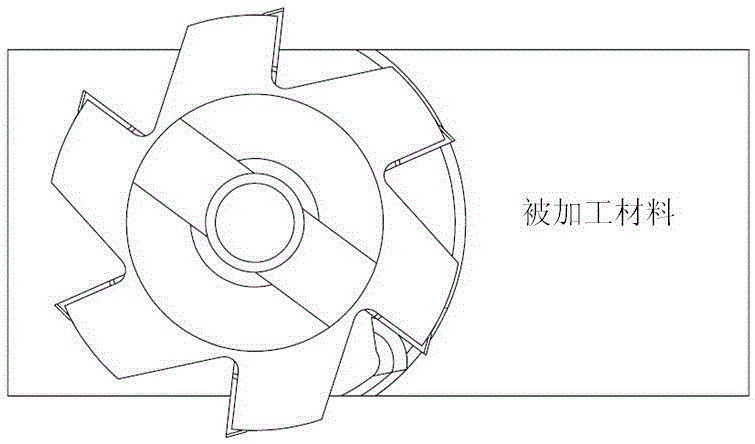

Coating failure test device under the common action of load shock and thermal shock cycle

A technology of co-action and test equipment, applied in the direction of measuring equipment, instruments, scientific instruments, etc., to achieve the effect of simple structure, high degree of automation, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

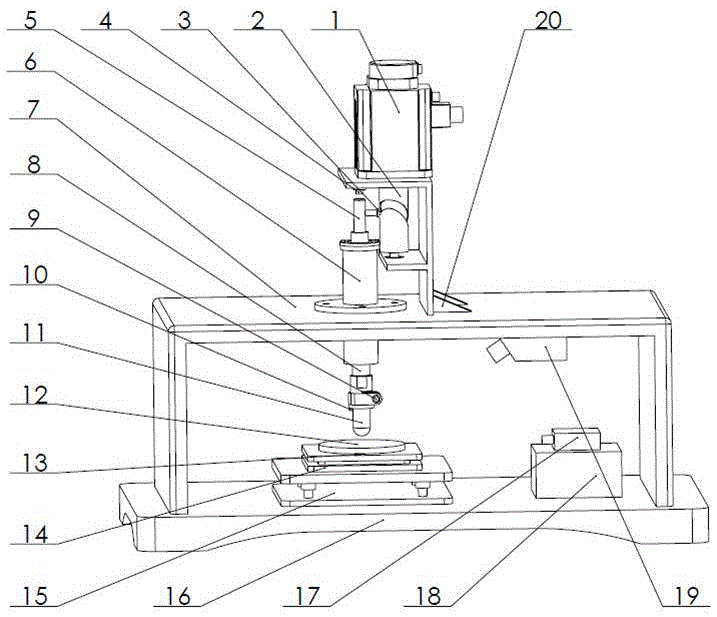

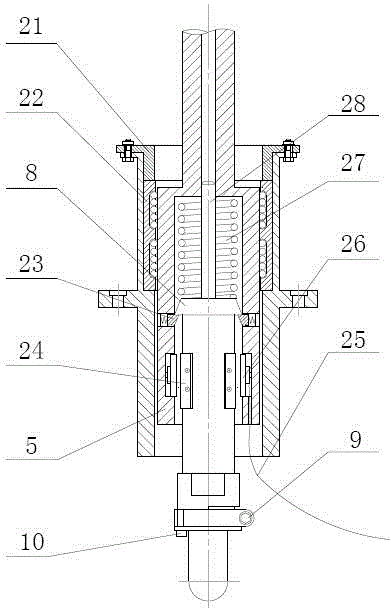

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] like figure 2 , image 3 As shown, the present invention includes a support frame 7, a base 16, a servo motor 1, a cylindrical cam 2, an impact mechanism, a precision hydraulic lifting platform 15, a force measuring platform 14, a coating sample 12, an infrared temperature measuring device 17 and a laser transmitter 19; the laser transmitter 19 is installed on the lower right side of the support frame 7; the servo motor 1, the cylindrical cam 2 and the impact mechanism are all installed on the support frame 7, and the impact mechanism can move freely up and down, including circular Disk outer sleeve 6, cylindrical rod inner sleeve 5 and spring buffer mechanism, disk outer sleeve 6 is fixedly connected to support frame 7 through the middle disk, cylindrical rod inner sleeve 5 is placed outside the disk through linear bearing 22 In the sleeve 6, the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com