System and method for displacing shale gas with CO2 and simulating and testing adsorption and desorption of shale to shale gas or CO2

A simulation test, shale gas technology, applied in the direction of measuring device, material analysis, material analysis through optical means, etc., can solve the problems of inability to realize real-time monitoring of replacement effect, less shale, etc., to reduce test error, reduce The effect of small test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

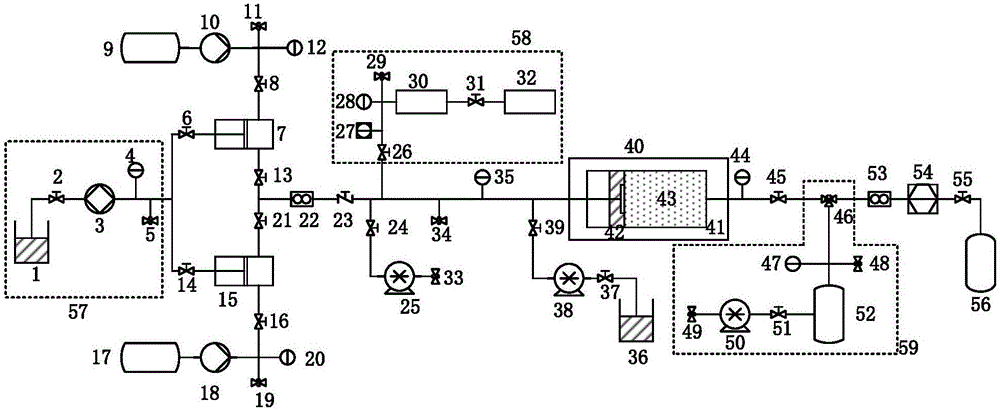

[0045] Such as figure 1 Shown, a CO 2 Replacement shale gas simulation test device, including CO 2 Cylinder 9 and CH 4 Cylinder 17, the CO 2 Cylinder 9 and CH 4 The gas cylinder 17 is connected to the input ends of the first piston container 7 and the second piston container 15 respectively. The power driving ends of the first piston container 7 and the second piston container 15 are connected with a hydraulic power driving system 57, and the output ends are both connected to the sand filling The input end of the pipe 41 is provided with a vacuum pump 25 and a calibration system 58 on the connecting pipeline. The sand filling pipe 41 is placed in the thermostat 40 and is connected with an axial pressure pump 38. The output end is connected to the exhaust gas recovery container 56, and The pipeline is provided with an external gas analyzer 54 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com