Nondestructive testing method of residual stress of thermally grown oxide layers in thermal barrier coatings

An oxide layer, non-destructive testing technology, used in force/torque/work measuring instruments, measuring devices, material excitation analysis, etc. The effect of strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

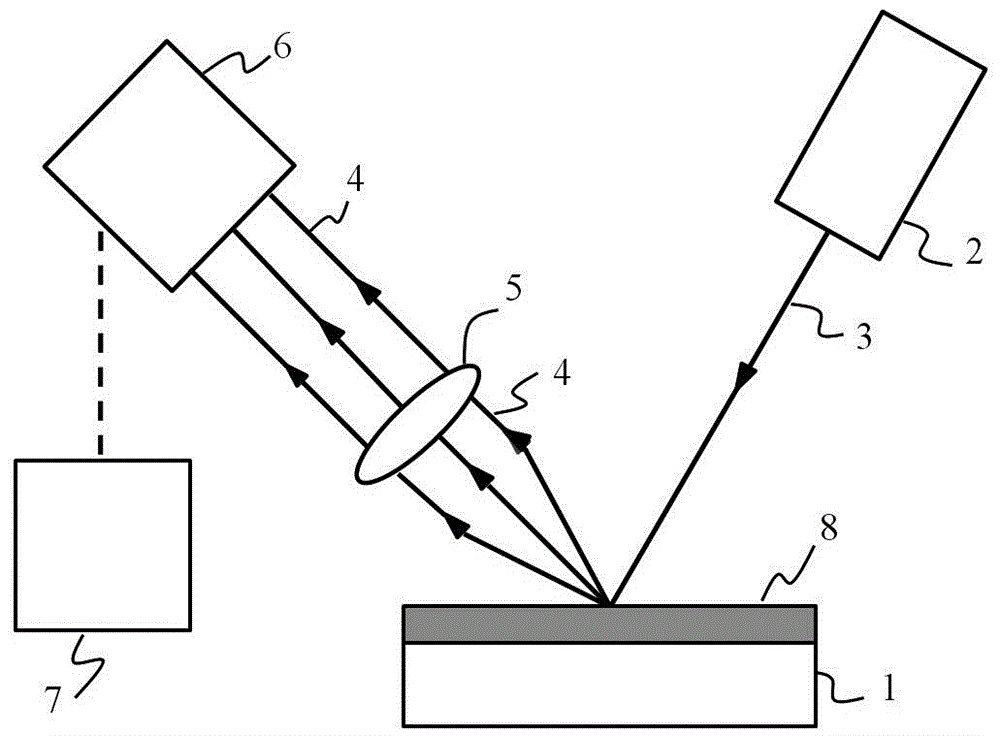

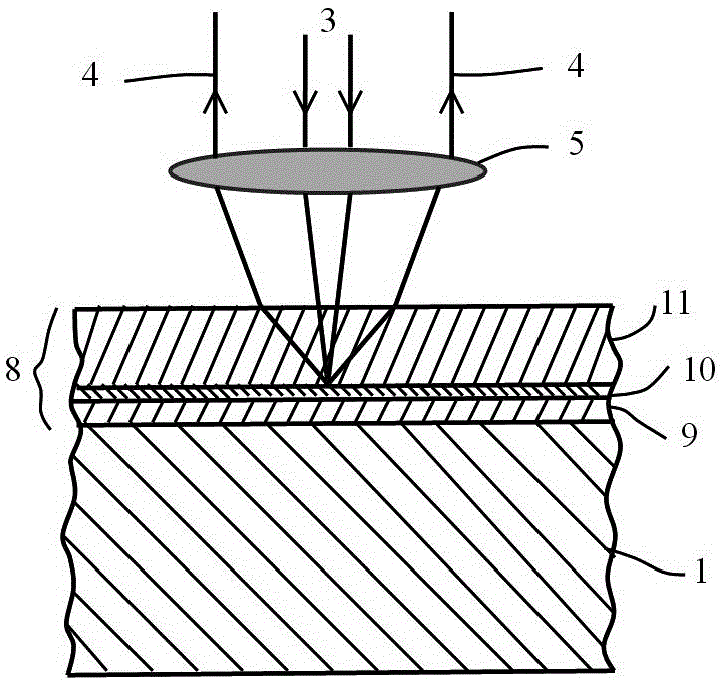

Method used

Image

Examples

Embodiment 1

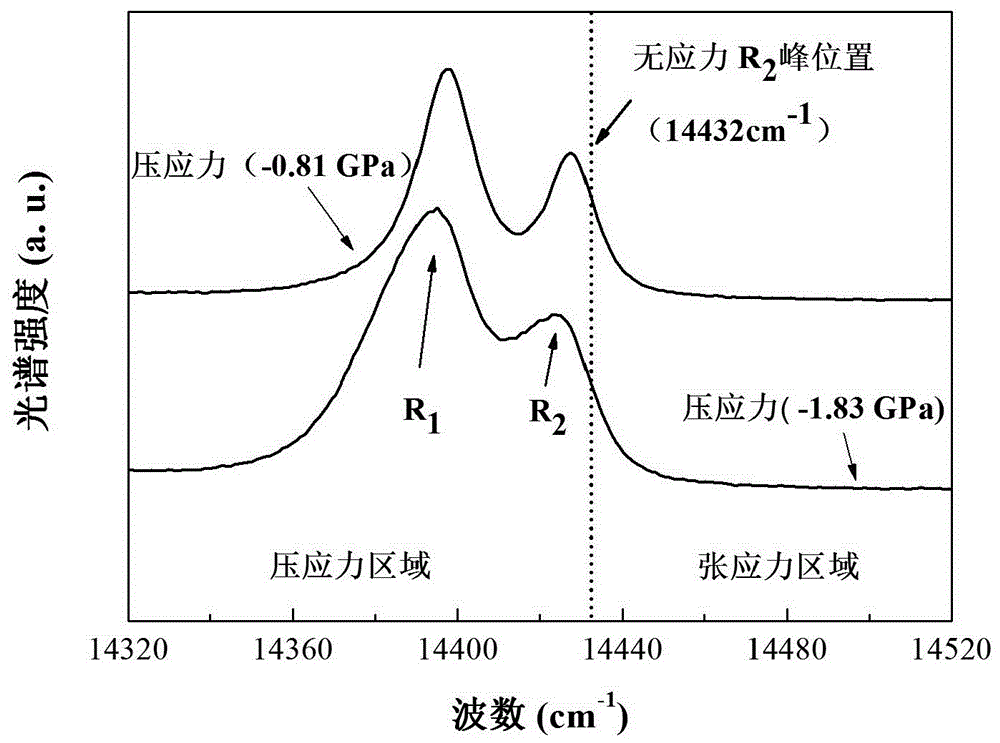

[0056] Using Cr 3+ Measurement of α-Al formed on the surface of the metal bonding layer after special processes (vacuum diffusion treatment, stress relief heat treatment, pre-oxidation treatment or oxidation after high-temperature service, etc.) by fluorescence piezometry 2 o 3 Stress distribution in the layer. Including the following steps:

[0057] Step (1) pretreating, for example, GH3128 nickel-based superalloy, including: roughening and purifying the surface of the metal substrate to be sprayed;

[0058] The size of the superalloy can be Φ30mm×5.8mm. It is sprayed with 20# white corundum sand at a working pressure of 0.4-0.5MPa, followed by ultrasonic cleaning with ethanol for 5 minutes, and then blown dry with compressed air.

[0059] Step (2) Depositing a CoNiCrAlY metal bonding layer on the surface of the treated metal substrate by using a low-pressure plasma spraying (LPPS) process, the thickness of which is 80-100 μm. In addition to the above-mentioned low-pressu...

Embodiment 2

[0068] Using Cr 3+ Fluorescence piezospectroscopy was used to detect the stress change of TGO layer of YSZ coating prepared by PS-PVD process before and after thermal shock. Including the following steps.

[0069] Step (1) pretreating the nickel-based superalloy includes: roughening and purifying the surface of the metal substrate to be sprayed.

[0070] For example, the size of the GH3128 nickel-based superalloy can be 25mm×25mm×2.7mm. First, it is sandblasted with 20# white corundum sand, and the working pressure is 0.4-0.5MPa, followed by ethanol ultrasonic cleaning for 5 minutes, and then compressed air. blow dry.

[0071]Step (2) Depositing a CoNiCrAlY metal bonding layer on the surface of the treated metal substrate by using LPPS process, the thickness of which is 80-100 μm. In addition to the LPPS process, VPS, HVOF and other processes can also be used.

[0072] Step (3) Before spraying the ceramic layer on the surface of the metal bonding layer, in order to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com