Die-free digital adaptation method for dental prosthesis

An oral prosthesis and prosthesis technology, which is applied to dental prostheses, additive manufacturing, dentures, etc., can solve the problems that product deformation cannot be directly measured, the measurement accuracy of calipers is limited, and the accuracy cannot be analyzed, so as to shorten the production time and save money. The effect of manpower and easy data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described in further detail with reference to the accompanying drawings and specific embodiments.

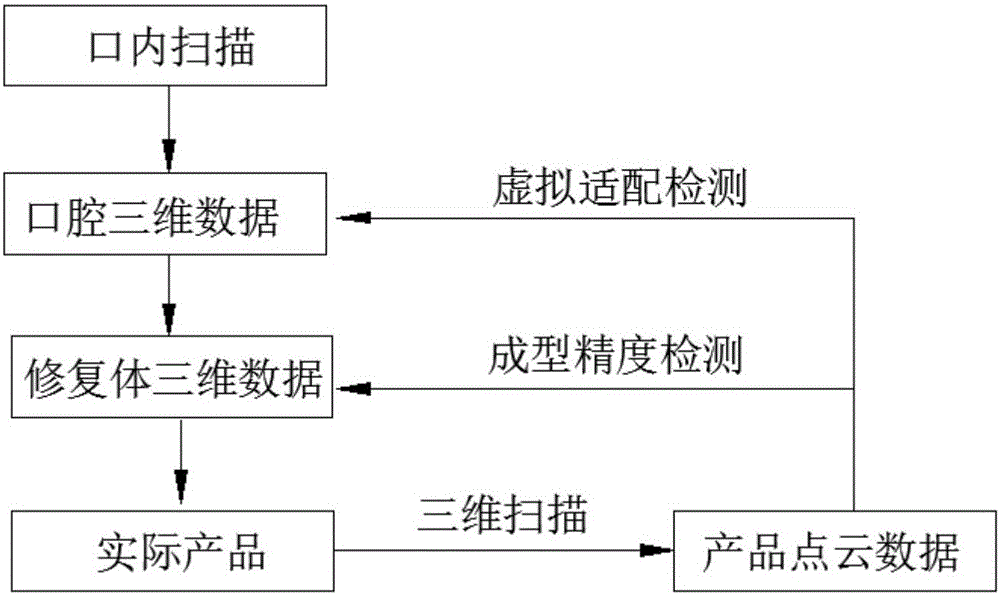

[0035] The moldless digital adaptation process for oral restorations disclosed in the present invention, such as figure 1 Shown.

[0036] The entire process is to obtain three-dimensional data of the oral cavity through intraoral scanning, and then design a dental restoration model based on this data, and then manufacture it to obtain the product entity. Then use reverse engineering technology to obtain product point cloud data, compare this data with the product design model in the software, and match the three-dimensional data of the oral cavity.

[0037] Any product will inevitably have errors and deformations in the manufacturing process. This is especially true for dental restoration products. Because they are used in the oral cavity, they have higher requirements for dimensional accuracy, shape accuracy and matching. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com