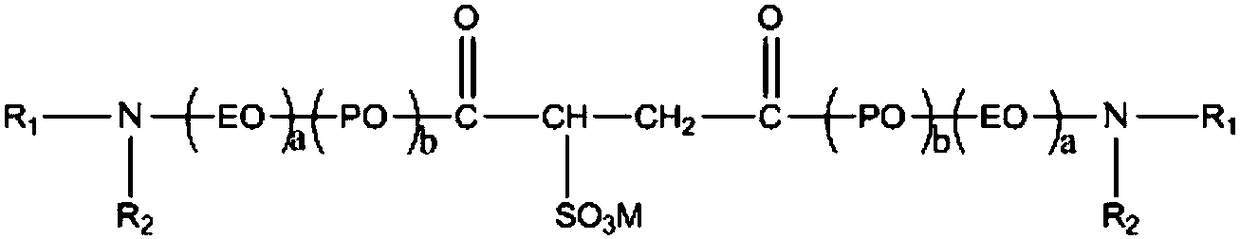

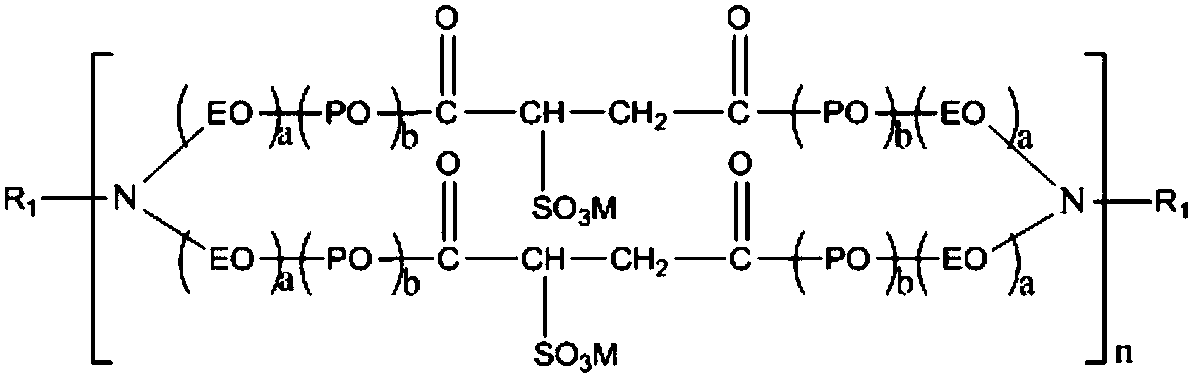

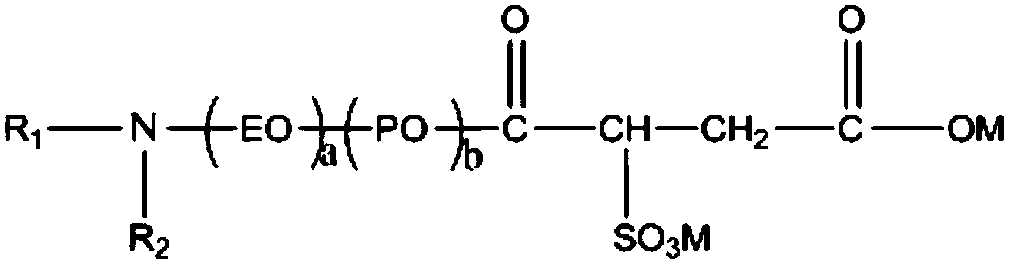

Gemini alkylamine ether succinate sulfonate surfactant and preparation method thereof

A succinic sulfonate and surfactant technology, applied in the chemical field, can solve the problems of poor compatibility of anionic surfactants, and achieve the effects of curbing the product from yellowing, good environmental protection, and curbing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of didodecanyl secondary amine ether (5EO) diester sodium succinate sulfonate shown in formula VII

[0029]

[0030] First put 2.1mol didodecanyl secondary amine ether (5EO) and 1mol maleic anhydride into the experimental device equipped with stirrer, thermometer, water separator and condenser tube, the whole experimental device is inerted 3 times, and finally pass Enter the nitrogen protection, open the condenser, add the catalyst, and then carry out the double esterification reaction at a reaction temperature of 100-240°C. During the reaction, a water separator is used to separate the water. The reaction time is 3-20h, and the acid value is less than 15. Then it is considered that the diesterification reaction is over; cool the product to 50±30°C, use 32% NaOH solution to neutralize to pH=7±0.5, and enter the next step; in the experimental device equipped with a condenser and a thermometer, add cooling And the 50% solution of the neutralized diester and...

Embodiment 2

[0032] Preparation of dioctadecyl secondary amine ether (7EO) monoester sodium succinate sulfonate shown in formula VIII

[0033]

[0034] First put 1.1 mol of dioctadecyl secondary amine ether (7EO) and 1 mol of maleic anhydride into an experimental device equipped with a stirrer, thermometer, water separator and condenser tube. Enter the nitrogen protection, open the condenser, add the catalyst, and then carry out the monoesterification reaction at a reaction temperature of 80-120°C, the reaction time is 3-20h, and the acid value is less than 120, it is considered that the monoesterification reaction is over; the product Cool to 50±30°C, use 32% NaOH solution to neutralize to pH=7±0.5, and enter the next step; in the experimental device equipped with a condenser and a thermometer, add the cooled and neutralized monoester and 0.52mol A 50% solution of sodium pyrosulfite is fed with nitrogen gas, and the reaction temperature is 85-155°C and vigorously stirred for sulfonatio...

Embodiment 3

[0036] The preparation of dodecyl primary amine ether (3EO) diester sodium succinate sulfonate shown in formula IX

[0037]

[0038]First put 1.2 mol of dodecyl primary amine ether (3EO) and 1 mol of maleic anhydride into the experimental device equipped with a stirrer, thermometer, water separator and condenser tube. The whole experimental device is inerted 3 times, and finally the Nitrogen protection, open the condenser, add catalyst, and then carry out diesterification reaction at a reaction temperature of 100-240°C. During the reaction, use a water separator to separate water. The reaction time is 3-20h, and the acid value is less than 15. The diesterification reaction is completed; cool the product to 50±30°C, use 32% NaOH solution to neutralize to pH=7±0.5, and enter the next step; in the experimental device equipped with a condenser and a thermometer, add cooling and neutralizing The mixed diester and 50% solution of 0.53mol sodium metabisulfite are fed with nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com