A kind of preparation method of heavy metal ion adsorbent

A technology for heavy metal ions and adsorbents, applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of GO suspension: Dissolve 1gGO in 100mL distilled water, and sonicate for 30min at a frequency of 600w;

[0050] (2) Preparation of GO-MT mixed suspension: Weigh 0.05g of MT powder and add it to 10mL of the above-prepared GO suspension, 500r / min magnetic stirring for 10min, and 600w ultrasonication for 30min to obtain a GO-MT uniform mixed suspension;

[0051] (3) Prepare GO-MT-CS mixed liquid: add 0.2mL acetic acid to MT-GO mixed suspension, then add 0.2g CS powder, and stir magnetically at 500r / min for 2h to obtain a uniform viscous liquid;

[0052] (4) Formation of G-MT-CS hydrogel: Add 0.5g VC to the liquid obtained in (3) above, stir magnetically at 500r / min for 10min, so that VC is fully dispersed in the mixture, and then place it at 50 Reduction reaction in an oven at ℃ for 12 hours to obtain G-MT-CS hydrogel;

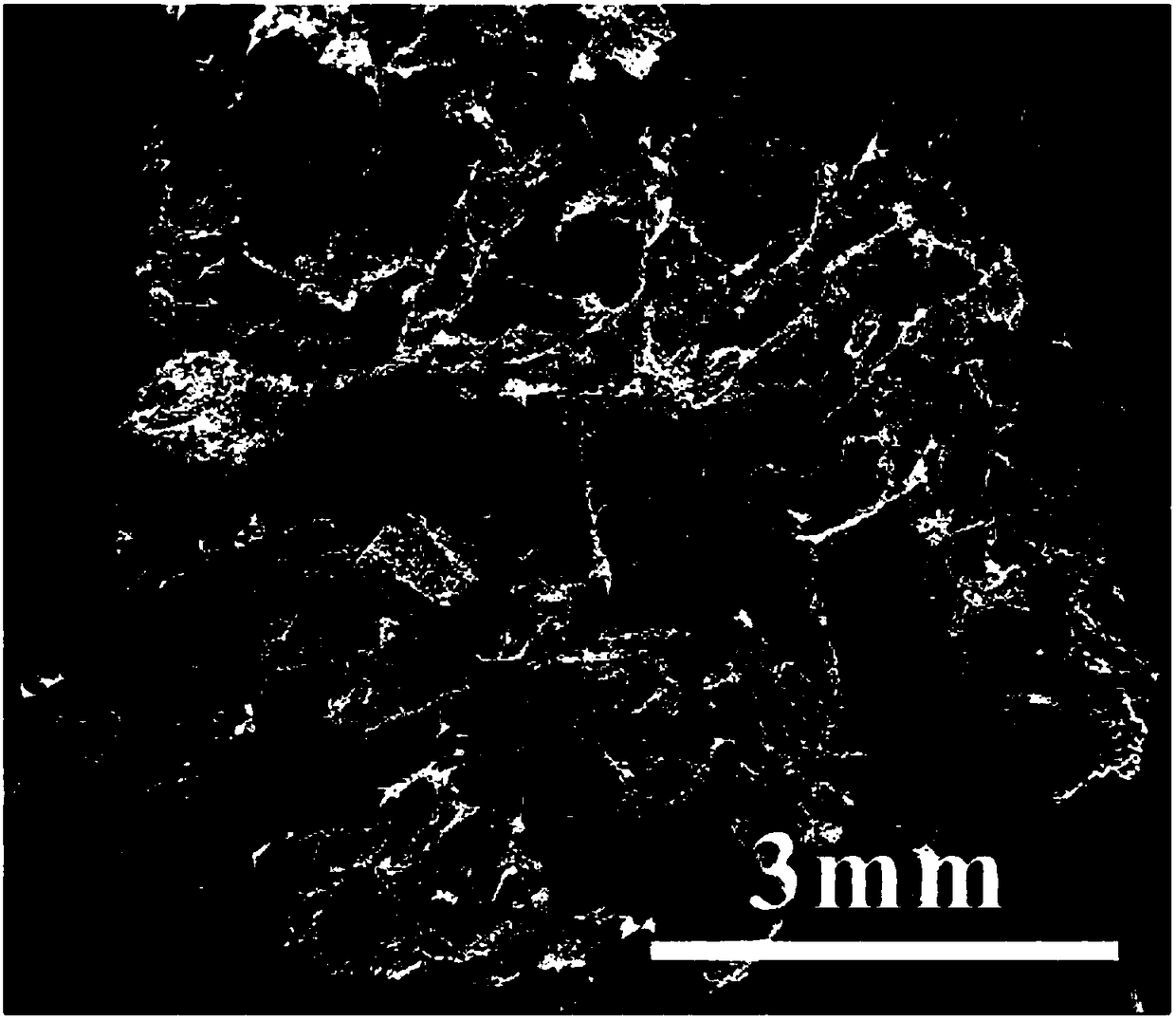

[0053] (5) Preparation of G-MT-CS airgel: freeze-dry the G-MT-CS hydrogel at -50°C and a vacuum of 15Pa to obtain G-MT-CS airgel .

...

Embodiment 2

[0060] (1) Prepare GO suspension: Dissolve 1gGO in 100mL distilled water, and ultrasonicate at 600w for 30min;

[0061] (2) Preparation of GO-MT mixed suspension: Weigh 0.1gMT powder into 10mL of the above-prepared GO suspension, 500r / min magnetic stirring for 10min, 600w ultrasonication for 30min to obtain GO-MT uniform mixed suspension;

[0062] (3) Preparation of GO-MT-CS mixture: add 0.2 mL of acetic acid to the MT-GO suspension, then add 0.2 g of CS powder, and stir magnetically at 500 r / min for 2 h. Obtain a uniform viscous liquid;

[0063] (4) Formation of G-MT-CS hydrogel: Add 0.5g VC to the liquid obtained in (3) above, stir magnetically at 500r / min for 10min, so that VC is fully dispersed in the mixture, and then place it at 50 The G-MT-CS hydrogel was obtained in an oven at ℃ for 12 hours;

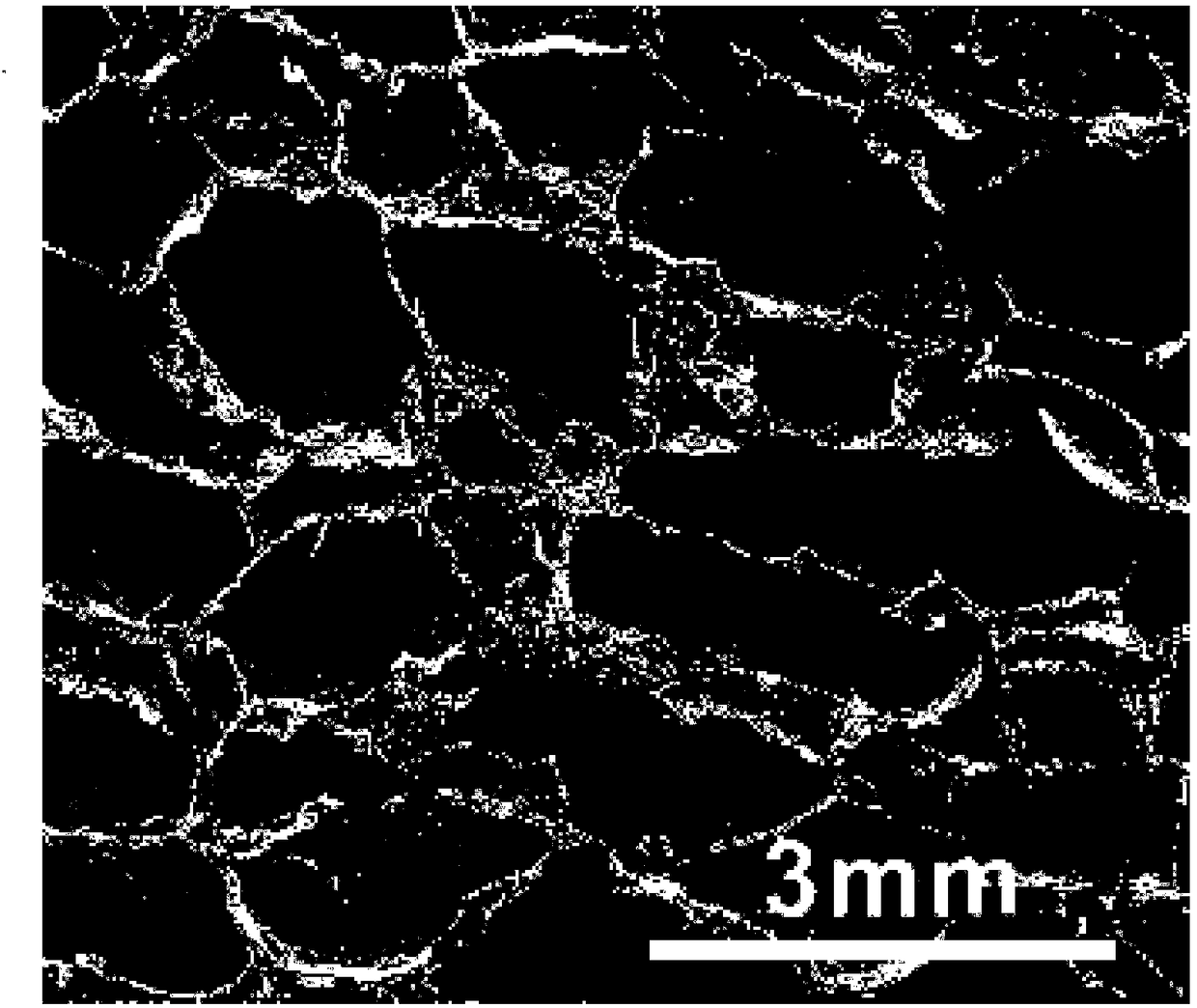

[0064] (5) Preparation of G-MT-CS airgel: freeze-dry the G-MT-CS hydrogel at -50°C and a vacuum of 15Pa to obtain G-MT-CS airgel .

Embodiment 3

[0066] (1) Prepare GO suspension: Dissolve 1gGO in 100mL distilled water, and ultrasonicate at 600w for 30min;

[0067] (2) Preparation of GO-MT mixed suspension: Weigh 0.2g of MT powder into 10mL of the GO suspension prepared above, stir magnetically at 500r / min for 10min, then ultrasonicate at 600w for 30min to obtain a uniform mixed suspension of GO-MT;

[0068] (3) Prepare the GO-MT-CS mixture: add 0.2mL acetic acid to the MT-GO suspension, then add 0.2gCS powder, and stir magnetically at 500r / min for 2h to obtain a uniform viscous liquid;

[0069] (4) Formation of G-MT-CS hydrogel: Add 0.5g VC to the mixed solution obtained in (3) above, stir magnetically at 500r / min for 10min, so that VC is fully dispersed in the mixed solution, and then place it in G-MT-CS hydrogel was obtained in an oven at 50°C for 12 hours;

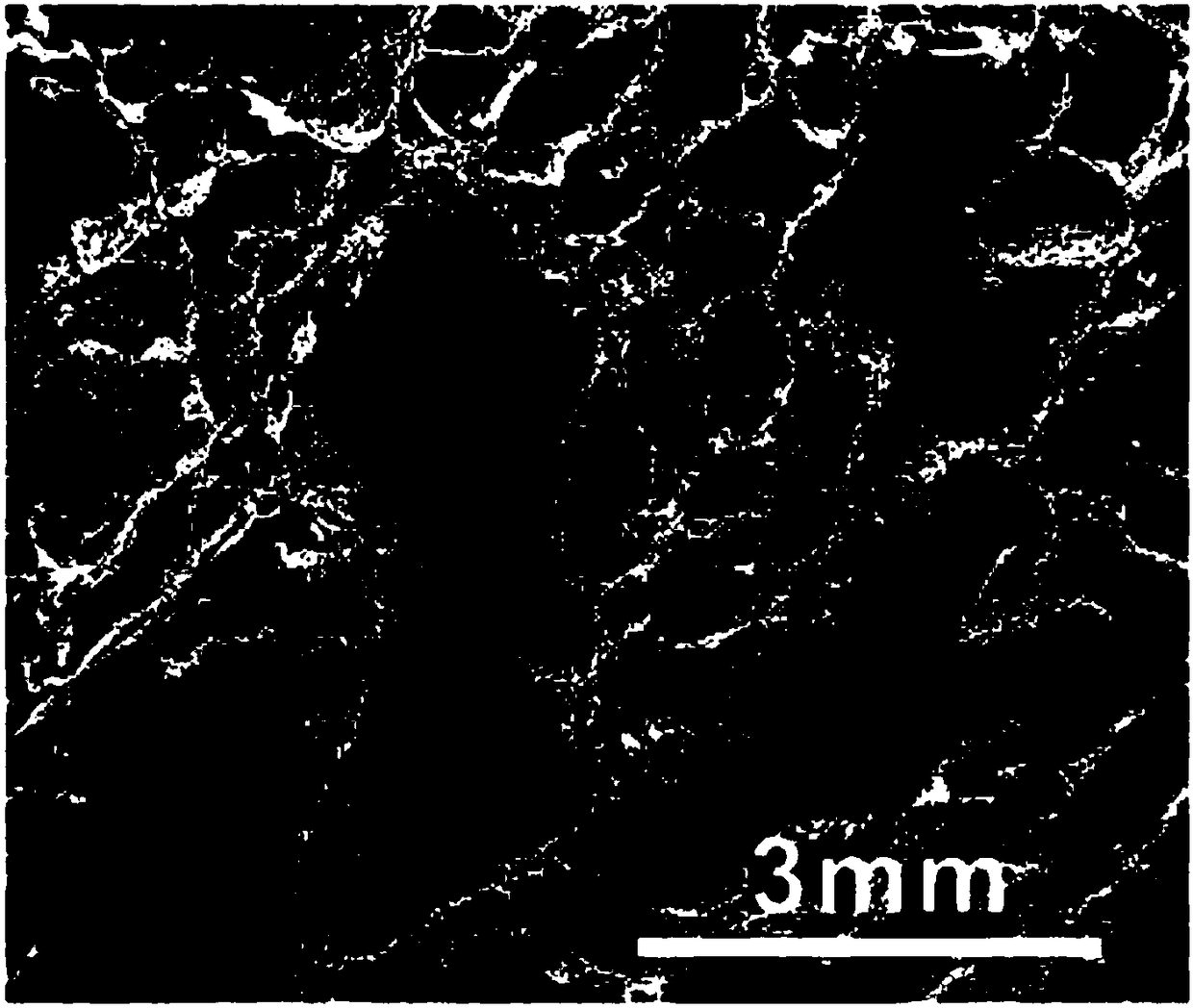

[0070] (5) Preparation of G-MT-CS airgel: freeze-dry the G-MT-CS hydrogel at -50°C and a vacuum of 15Pa to obtain G-MT-CS airgel .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com