Preparation method for load type TiO2 catalyst for ester exchange compound diphenyl oxalate

A diphenyl oxalate, supported technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as cumbersome preparation process, and achieve low energy consumption, no corrosion of equipment, and operation. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

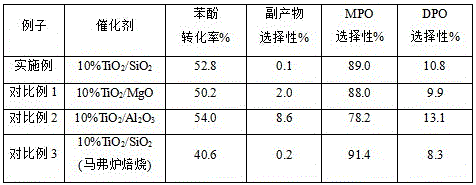

Examples

preparation example Construction

[0020] Supported TiO used in the synthesis of diphenyl oxalate by transesterification of the present invention 2 The preparation method of catalyst, step is as follows,

[0021] 1) Weighing a certain amount of titanium source and dissolving it in absolute ethanol, stirring thoroughly, to obtain an impregnation solution; the titanium source is tetraethyl titanate, tetraisopropyl titanate or tetrabutyl titanate. The purpose of using absolute ethanol is to better realize the dispersion of the titanium source, so that the speed of the subsequent hydrolysis of the titanium source can be eased. Theoretically speaking, the more absolute ethanol is added, the more dispersed the titanium source, the slower the subsequent hydrolysis rate, and the relatively more uniform and finer the prepared catalyst. But from the perspective of laboratory or cost saving, absolute ethanol is mostly 5-100 times (molar ratio) of titanium source.

[0022] Reasons for choosing anhydrous ethanol to dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com