A kind of micelle modified nano zero-valent iron particle and its preparation method and application

A technology for modification and modification of nano-zero-valent iron, which is applied in the field of preparation and modification of nano-materials, can solve problems such as increased application costs and secondary pollution of the environment, and achieves easy operation, good biocompatibility, and oxidation resistance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

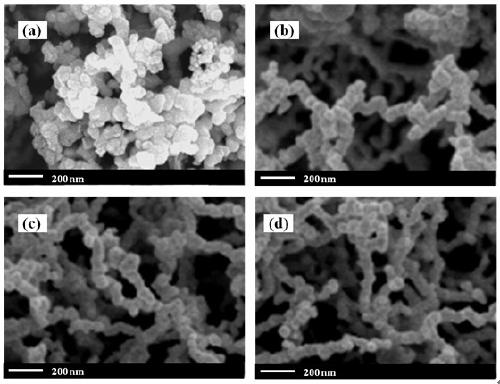

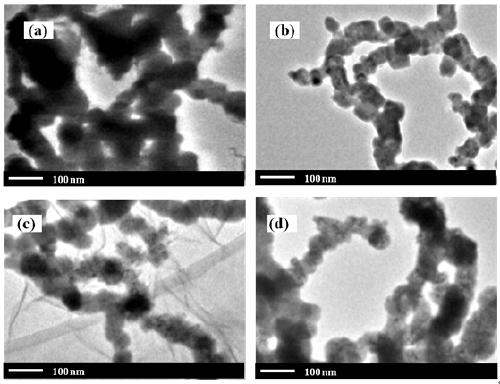

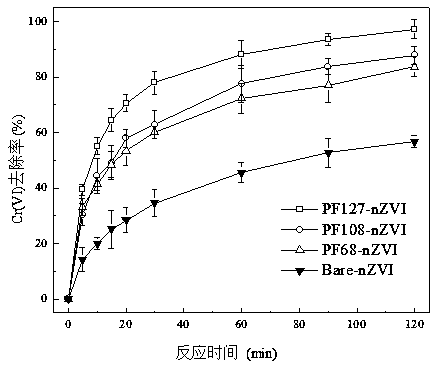

[0037] Preparation of Nano-sized Zero-valent Iron Modified by Three Poloxamers (Poloxamer F68, Poloxamer F108 and Poloxamer F127) and Its Removal of Cr(VI)

[0038] A poloxamer modified nano-zero-valent iron, the modified nano-zero-valent iron includes nano-zero-valent iron and poloxamers (poloxamer F68, poloxamer F108 and poloxamer F127), poloxamer Sharm self-assembles to form micelles coated on the surface of nano-zero-valent iron, and poloxamer micelles modify the surface of nano-zero-valent iron; the concentration of poloxamer added to the modified nano-zero-valent iron is 5mmol / L ; The temperature of the solution is controlled at 30° C. when the poloxamer is added in the preparation process of the nanometer zero-valent iron.

[0039] (1) FeSO 4 Solution preparation: weigh 20g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer to a 100mL volumetric flask, set the volume to the mark, and shake well to obtain 0.7M FeSO 4...

Embodiment 2

[0050] Preparation of Poloxamer F127 Modified Nanoscale Zero-Valent Iron and Its Removal of Orange II Dye

[0051] A poloxamer-modified nano-zero-valent iron, the modified nano-zero-valent iron includes nano-zero-valent iron and poloxamer F127, and the poloxamer F127 self-assembles to form micelles coated on the surface of the nano-zero-valent iron, Poloxamer F127 micelles are used to modify the surface of nano-zero-valent iron; the concentration of poloxamer F127 in the modified nano-zero-valent iron is 0.5mmol / L; When using F127, the temperature of the solution is controlled at 25°C.

[0052] (1) FeSO 4 Solution preparation: weigh 14.3g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve it and transfer it to a 100mL volumetric flask, set the volume to the mark, and shake well to obtain 0.5mol / L FeSO 4 solution.

[0053] (2) NaBH 4 Preparation of the solution: Weigh 5.67g, put it in a beaker, add an appropriate amount of ultrapure w...

Embodiment 3

[0058] Preparation of Nano-sized Zero-Valent Iron Modified by Poloxamer F127 and Removal of Metronidazole

[0059] A poloxamer-modified nano-zero-valent iron, the modified nano-zero-valent iron includes nano-zero-valent iron and poloxamer F127, and the poloxamer F127 self-assembles to form micelles coated on the surface of the nano-zero-valent iron, Poloxamer F127 micelles are used to modify the surface of nano-zero-valent iron; the concentration of poloxamer F127 in the modified nano-zero-valent iron is 8 mmol / L; the addition of poloxamer to the nano-zero-valent iron preparation process The temperature of the solution at F127 was controlled at 40°C.

[0060] (1) FeSO 4 Solution preparation: weigh 25.7g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer it to a 100mL volumetric flask, set the volume to the mark, and shake well to obtain 0.9mol / L FeSO 4 solution.

[0061] (2) KBH 4 Solution preparation: Weigh 7.7g and put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com