Preparation method of graphene

A technology of graphene and graphene, which is applied in the field of graphene preparation, can solve problems such as high preparation cost, easy agglomeration, and impact on application, and achieve the effects of simple preparation method, high single-layer rate, and uniform sheet diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of graphene, comprising: ultrasonicating the graphene oxide aqueous solution, then adjusting its pH value to be alkaline, adding a reducing agent and an alcohol polymer, and heating and reacting to obtain graphene.

[0029] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0030] In the present invention, the graphene oxide aqueous solution is firstly ultrasonicated; the mass concentration of graphene oxide in the graphene oxide aqueous solution is preferably 0.2%-0.35%, more preferably 0.25%-0.35%, and most preferably 0.3%. If the mass fraction of graphene oxide in the graphene oxide aqueous solution is too low, the efficiency will be low, and if it is too high, it will affect the subsequent reduction effect, resulting in incomplete reduction and agglomeration.

[0031] Ultrasound can further stratify graphene oxide, disperse and break up at the same ti...

Embodiment 1

[0040] Ultrasonicate 2L graphene oxide aqueous solution with a mass concentration of 0.3% at 20KHz, 2KW power for 2h, adjust its pH value to 10.5 with ammonia water, then add 3.6g hydrazine hydrate and 2g polyethylene glycol to stir, and control the reaction temperature to 90°C , reacted for 14 hours, and finally cooled down naturally, and washed with water until the pH value was 8 to obtain a graphene aqueous solution.

[0041] figure 1 It is the appearance photo of the graphene aqueous solution obtained in embodiment 1.

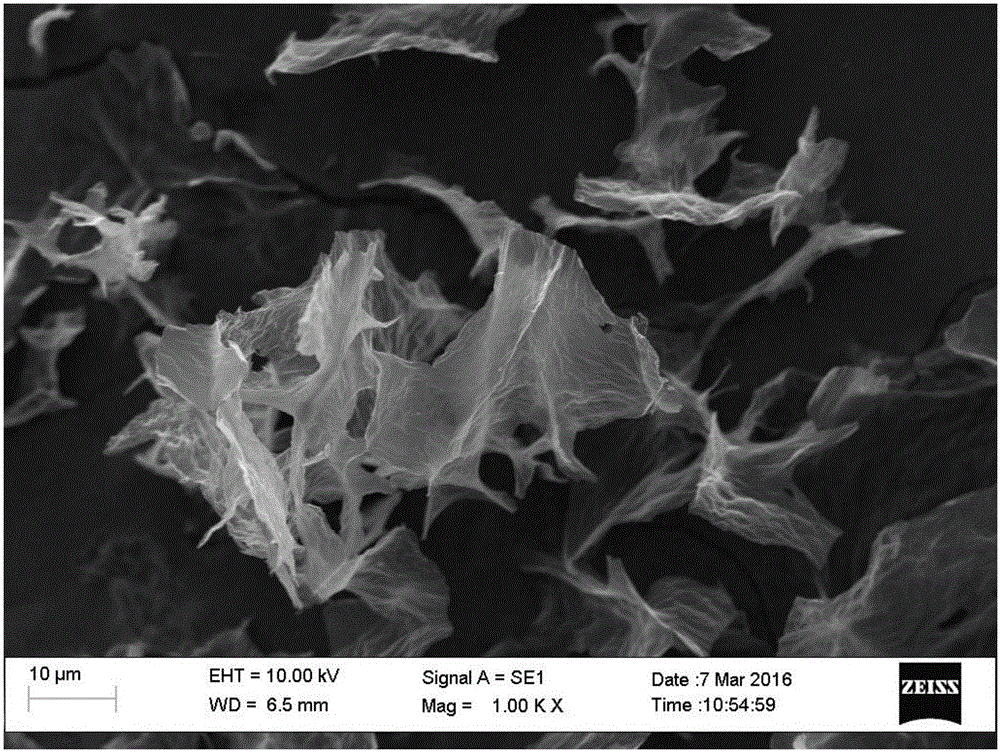

[0042] Utilize scanning electron microscope to scan the Graphene that obtains in embodiment 1, obtain its scan photo such as figure 2 shown.

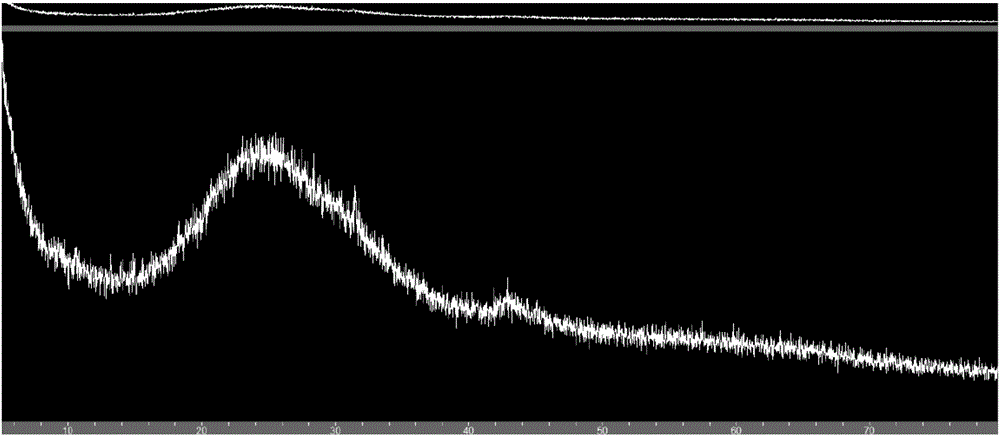

[0043] Utilize X-ray diffraction to analyze the graphene that obtains in embodiment 1, obtain its X-ray diffraction pattern, as image 3 shown.

[0044] Utilize atomic force microscope to analyze the graphene obtained in embodiment 1, obtain its atomic force micrograph, as Figure 4 shown. Depend on Figure 4 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com