A method for efficiently preparing artificial zeolite from water plant sludge and its application

A technology of artificial zeolite and sludge, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problems of poor reuse, incomplete treatment, high energy consumption, and achieve high utilization High, improve production efficiency, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

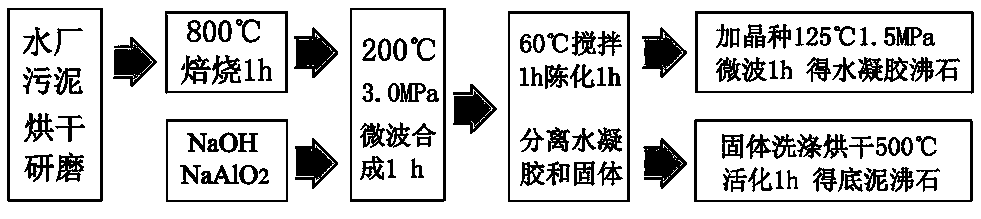

[0034] like figure 1 The shown process flow prepares hydrogel artificial zeolite and bottom mud artificial zeolite, specifically as follows:

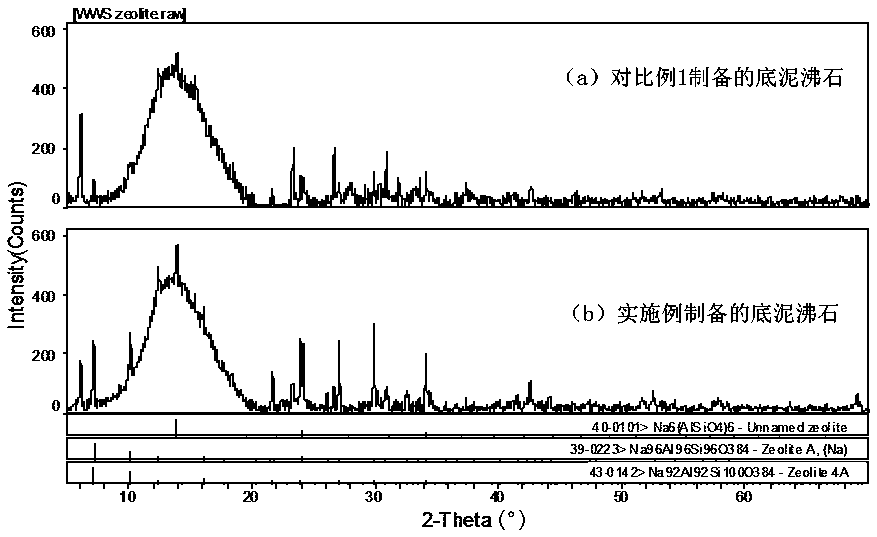

[0035] (1) Crush and dry the sludge from the water plant, then grind it into powder and spread it on a large porcelain boat, and bake it at 800°C for 1 hour, the inner and outer layers of soil will appear pottery red. white, indicating that the roasting is not sufficient, and it needs to be mixed and then roasted until it is completely pottery red to obtain marl ash. At this time, the main component of marl ash is SiO 2 and AlPO 4 Crystalline powder, its XRD of insufficiently sintered inner soil and fully sintered topsoil as figure 2 It can be seen from the figure that if the roasting is not sufficient, there will be more impurities;

[0036] (2) Dissolve 7.5 g of marl in 50 mL of 0.5 mol / L NaOH solution, add 5.0 g of NaAlO 2 , and mix well to obtain the reaction mixture, the molar ratio of Si and Al in the reaction mixture is 1:1, ...

Embodiment 2

[0041] (1) Mash and dry the sludge from the waterworks, then grind it into powder and spread it evenly in a large porcelain boat, and bake it at 750°C for 1.2 hours. Both the inner and outer layers of the sludge appear pottery red, indicating that the roasting is complete. Marl ash is obtained. At this time, the main component of marl is SiO 2 and AlPO 4 crystal powder;

[0042] (2) Dissolve 6.0 g of marl in 50 mL of 0.6 mol / L NaOH solution, and then add 4.8 g of NaAlO 2 , and mix well to obtain the reaction mixture, the molar ratio of Si and Al in the reaction mixture is 1:1.2, the solid-liquid ratio is 0.12 (the mass ratio of marl ash to NaOH solution is 0.12), and the microwave hydrothermal synthesis instrument (microwave The wavelength is 12.2 cm, the frequency is 2450 MHz), and the temperature is raised to 100°C (upper limit: 1.2 MPa) in 10 minutes, and maintained for 3 minutes; the temperature is raised to 195°C in 14 minutes, and the reaction is maintained for 30 minu...

Embodiment 3

[0047] (1) Smash and dry the sludge from the waterworks, then grind it into powder and spread it in a large porcelain boat, and bake it at 850°C for 0.8h. The inner and outer layers of the sludge are pottery red, indicating that the roasting is complete Marl ash is obtained. At this time, the main component of marl is SiO 2 and AlPO 4 crystal powder;

[0048] (2) Dissolve 7.5 g of marl in 50 mL of 0.4 mol / L NaOH solution, and then add 4.0 g of NaAlO 2 , and mix well to obtain a reaction mixture, the molar ratio of Si and Al in the reaction mixture is 1:0.8, the solid-liquid ratio is 0.15 (the mass ratio of marl ash to NaOH solution is 0.15), and the microwave hydrothermal synthesis instrument (microwave The wavelength is 12.2 cm, the frequency is 2450 MHz), the temperature is raised to 100°C (upper limit: 1.2 MPa) in 10 minutes, and maintained for 3 minutes; the temperature is raised to 205°C in 16 minutes, and the reaction is maintained for 60 minutes; naturally cooled to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com