Preparation method of enzyme cross-linked mixed protein hydrolysate cement foaming agent

A technology of cement foaming agent and hydrolyzed protein, which is applied in the field of foaming agent, can solve the problems of low technological content, environmental protection and safety hazards in use, low research and development capabilities, etc., and achieve good foaming ratio and foam stability, Good application security, excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

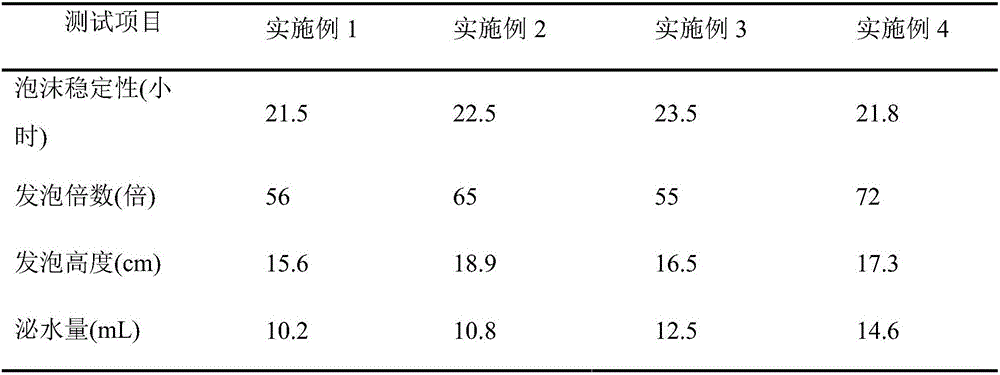

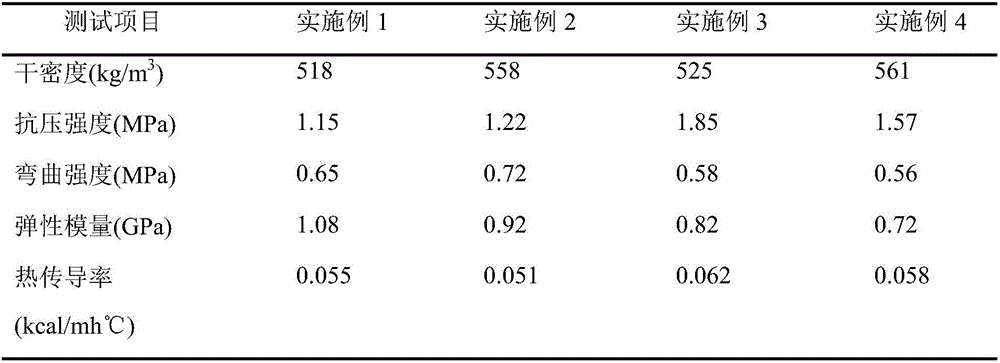

Examples

preparation example Construction

[0022] A preparation method of enzyme crosslinking mixed hydrolyzed protein cement foaming agent, the steps are as follows:

[0023] (1) Preparation of the first protein solution raw material: put the ground and dried animal hoof horns into a container, add water, then add sodium bisulfite, mix and soak overnight; place the mixed solution in a 50-60°C Put it in a water bath for 2-3 hours, then raise the temperature of the water bath to 100°C, add calcium hydroxide, and continue hydrolysis at 100°C for 10-12 hours to obtain a hydrolyzed solution, filter the obtained hydrolyzed solution, and adjust the pH to 7-8 spare;

[0024] (2) Preparation of the second protein solution raw material: take degreased and washed animal hair and put it into a container, first add water, then add sodium bisulfite, mix and soak overnight; put the mixed solution in a 50-60°C Put it in a water bath for 1-2 hours, then raise the temperature of the water bath to 100°C, add calcium hydroxide, and cont...

Embodiment 1

[0035] An enzyme crosslinking mixed hydrolyzed protein cement foaming agent comprises the following steps:

[0036] 1) First prepare the first hydrolyzed protein raw material: put 50 g of ground and dried animal hoof keratin into a container, add 1000 mL of water, then add 10 g of sodium bisulfite, and soak overnight. The mixed solution was left in a water bath at 60°C for 2 hours. Then the temperature of the water bath was rapidly raised to 100°C, and Ca(OH) 2 25g, continued hydrolysis at this temperature for 10 hours, filtered the prepared hydrolyzed solution, and adjusted the pH to 7 for later use.

[0037] 2) Preparation of the second hydrolyzed protein raw material: put 50 g of degreased and washed animal hair (human hair, waste cow wool) into a container, add 1000 mL of water, then add 2 g of sodium bisulfite, and soak overnight. The mixed solution was left in a water bath at 60°C for 1 hour. Then the temperature of the water bath was rapidly raised to 100°C, and Ca(...

Embodiment 2

[0046] An enzyme crosslinking mixed hydrolyzed protein cement foaming agent comprises the following steps:

[0047] 1) First prepare the first hydrolyzed protein raw material: put 50 g of ground and dried animal hoof keratin into a container, add 1000 mL of water, then add 7 g of sodium bisulfite, and soak overnight. The mixed solution was left in a water bath at 60°C for 2.5 hours. Then the temperature of the water bath was rapidly raised to 100°C, and Ca(OH) 2 22g, the hydrolysis was continued at this temperature for 11 hours, the prepared hydrolyzed solution was filtered, and the pH was adjusted to 7.5 for later use.

[0048] 2) Preparation of the second hydrolyzed protein raw material: put 50 g of degreased and washed animal hair (human hair, waste cow wool) into a container, add 1000 mL of water, then add 5 g of sodium bisulfite, and soak overnight. The mixed solution was left in a water bath at 60°C for 2 hours. Then the temperature of the water bath was rapidly rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com