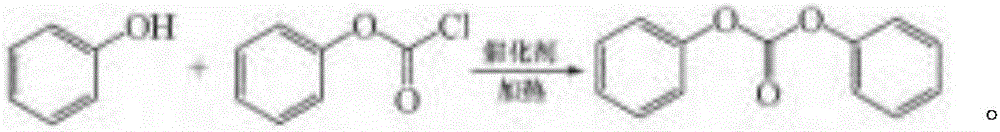

Synthetic method of phenyl chloroformate by taking phenol as raw material

A technology for the synthesis of phenyl chloroformate, which is applied in the preparation of phosgene or haloformate, organic chemistry, etc., can solve the problems of low production efficiency, achieve the effects of avoiding poisonous gas, avoiding waste water, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, add 94Kg phenol in the molten state in the phenol dropping tank, first open the A and B circulation refrigerators connected to the reaction tank, lower the temperature of the lower part of the reaction tank to 0 ° C, then add triphosgene to the lower part of the reaction tank, and The add-on of triphosgene is 299Kg, simultaneously in retort inner bottom, adds catalyzer, and the reaction time is 7 hours, gets middle control sample, gas phase normalization analyzes the area percentage of phenyl chloroformate and main by-product diphenyl carbonate; Next, Extract the above-mentioned central control sample once every 1 hour, so that step 3 continues to react until the area percentage of phenyl chloroformate and the main by-product diphenyl carbonate no longer increases, and the number of extractions is 10 times; again, the reaction tank after the above-mentioned extraction is used nitrogen gas After degassing, the tail gas is passed into the phosgene decomposition towe...

Embodiment 2

[0026] Add 94Kg phenol in the molten state to the phenol dropping tank, first turn on the A and B circulation refrigerators connected to the reaction tank, lower the temperature of the lower part of the reaction tank to 0 ° C, and then add triphosgene to the lower part of the reaction tank, and triphosgene The add-on of chloroformate is 297Kg, simultaneously adds catalyzer to the lower part in the retort, and the reaction time is 7 hours, gets in control sample, gas phase normalization analyzes the area percent of chloroformic acid phenyl ester and main by-product diphenyl carbonate; Next, above-mentioned The central control sample is extracted once every 1 hour, so that step 3 continues to react until the area percentage of phenyl chloroformate and the main by-product diphenyl carbonate no longer increases, and the number of extractions is 10 times; again, the reaction tank after the above extraction is purged with nitrogen gas Finally, pass the tail gas into the phosgene deco...

Embodiment 3

[0031] Add 94Kg phenol in the molten state to the phenol dropping tank, first turn on the A and B circulation refrigerators connected to the reaction tank, lower the temperature of the lower part of the reaction tank to 0 ° C, and then add triphosgene to the lower part of the reaction tank, and triphosgene The add-on of chloroformate is 298Kg, simultaneously adds catalyzer to bottom in reaction tank, and the reaction time is 7 hours, gets middle control sample, gas phase normalization analyzes the area percentage of phenyl chloroformate and main by-product diphenyl carbonate; Next, above-mentioned The central control sample is extracted once every 1 hour, so that step 3 continues to react until the area percentage of phenyl chloroformate and the main by-product diphenyl carbonate no longer increases, and the number of extractions is 10 times; again, the reaction tank after the above extraction is purged with nitrogen gas Finally, pass the tail gas into the phosgene decompositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com