Selenium-containing rubber material for tire and preparation method of material

A technology for rubber materials and tires, applied in the field of selenium-containing rubber materials for tires and their preparation, can solve problems such as irreparable losses, and achieve the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) In parts by mass, weigh raw materials: 100 parts of natural rubber NR, 3 parts of crosslinking agent, 1 part of accelerator CZ (N-cyclohexyl-2-benzothiazyl sulfenamide), 5 parts of active zinc oxide , 1 part of antioxidant 4010 (N-cyclohexyl-N'-phenyl-p-phenylenediamine), 30 parts of white carbon black, 10 parts of liquid coumarone, 1 part of titanate; the crosslinking agent is sulfur powder (95% by mass content of sulfur) and selenium powder (95% by mass content of selenium, directly purchased in the market, 100 orders) are mixed in a mass ratio of 1:0.25;

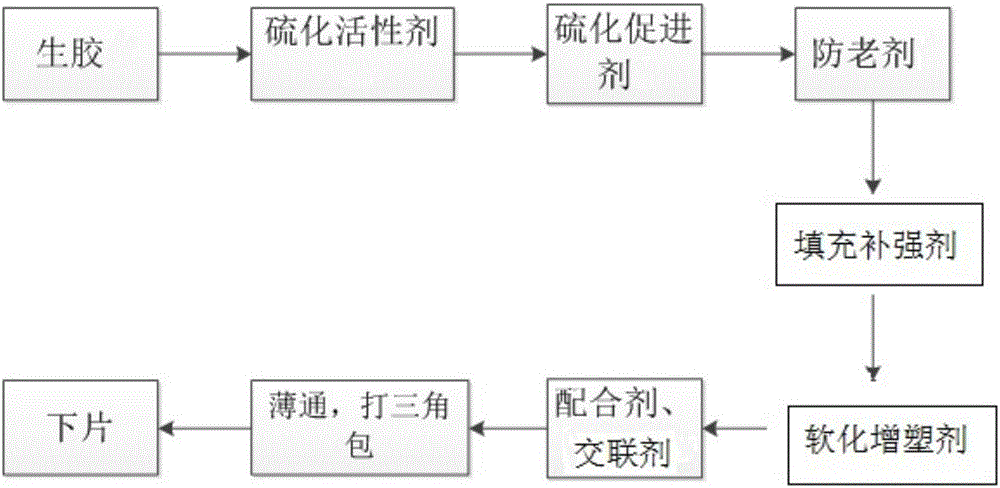

[0034] (2) Mixing: Add the materials weighed in step (1) into the internal mixer in order for mixing, the roller temperature is 50°C, and the feeding sequence is as follows: figure 1 As shown, the details are: natural rubber, active zinc oxide, accelerator CZ, anti-aging agent 4010, white carbon black, liquid coumarone, titanate, selenium powder, sulfur powder, thin through-out sheet, packed in a triangular bag...

Embodiment 2

[0036] (1) In parts by mass, weigh raw materials: 100 parts of natural rubber NR, 2 parts of crosslinking agent, 1 part of accelerator CZ (N-cyclohexyl-2-benzothiazyl sulfenamide), 5 parts of active zinc oxide , 1.5 parts of antioxidant 4010 (N-cyclohexyl-N'-phenyl-p-phenylenediamine), 35 parts of white carbon black, 8 parts of liquid coumarone; the cross-linking agent is sulfur powder (sulfur mass content 95% ) and selenium powder (selenium mass content 95%, direct purchase in the market, 100 orders) is mixed in a mass ratio of 1:1;

[0037] (2) Mixing: Add the materials weighed in step (1) into the internal mixer in order for mixing, the roller temperature is 50°C, and the order of addition is: natural rubber, active zinc oxide, accelerator CZ, anti-aging agent 4010, white Carbon black, liquid coumarone, selenium powder, sulfur powder, thin slices, packed into triangular bags, and sliced to obtain selenium-containing rubber materials.

Embodiment 3

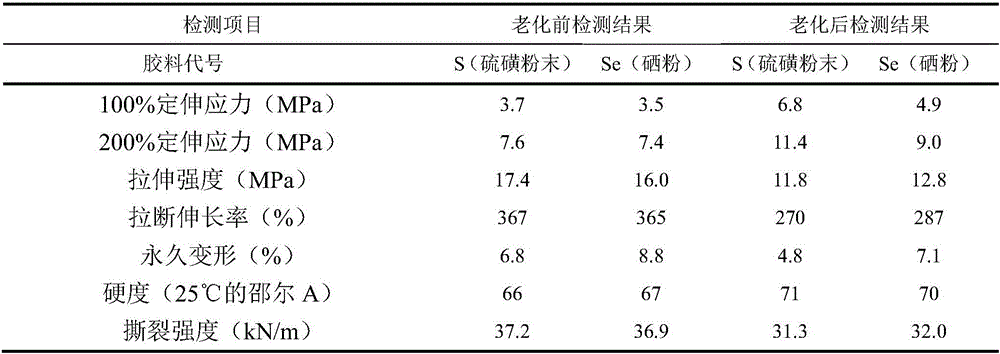

[0039] The difference between this example and Example 1 is that the crosslinking agent does not contain sulfur powder, all of it is selenium powder, and the prepared selenium-containing rubber material is recorded as Se (selenium powder). The heat aging performance test is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com