Preparation method of polylactic acid composite material

A composite material and polylactic acid technology, applied in the field of preparation of polylactic acid composite materials, can solve the problems of slow polylactic acid crystallization rate, product development limitation, unfavorable high-efficiency production, etc., and achieve comprehensive performance optimization, production cost reduction, and comprehensive energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of polylactic acid composite material, comprises the steps:

[0026] Step 1. Weigh 100 parts of polylactic acid, 0.5-2 parts of heat stabilizer, 0.5-3 parts of nucleating agent, 0.2-0.5 parts of crystallization accelerator, and 1-3 parts of organic activated nano-inorganic filler.

[0027] Specifically, the polylactic acid is L-type polylactic acid or D-type polylactic acid.

[0028] Specifically, the heat stabilizer is macromolecule hindered amine and phosphate compound, copper halide series heat stabilizer, triethyl phosphate, or lithium stearate.

[0029] Specifically, the nucleating agent is sodium phosphate, benzoate, or sorbitol.

[0030] Specifically, the accelerator is fatty amide, oleamide, or phthalamide.

[0031] Specifically, the organic activated nanofiller is nano talcum powder, nano montmorillonite, or nano calcium carbonate treated with an organic activator, and the organic activator is specifically a...

Embodiment 1

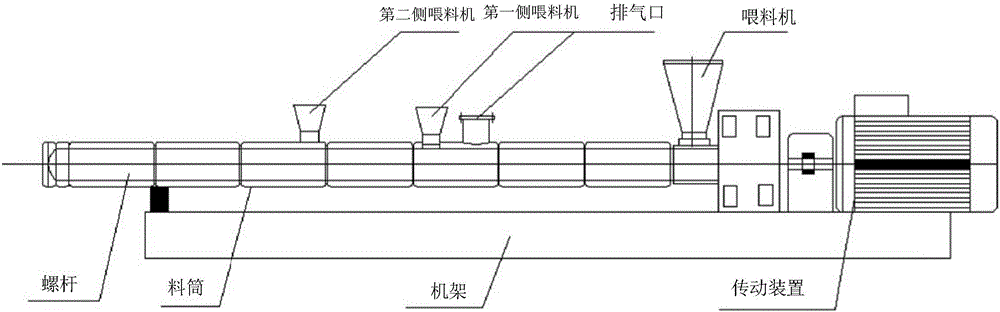

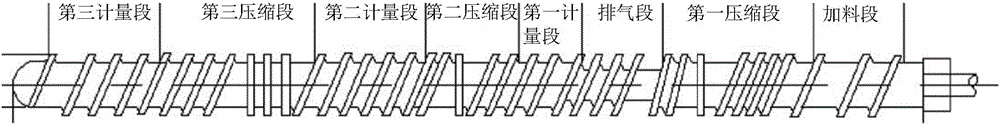

[0041] Take 50kg of undried polylactic acid and 0.5kg of triethyl phosphate, mix them evenly, and throw them into the feeder of the co-rotating twin-screw extruder, turn on the heated co-rotating twin-screw extruder, the melt pressure Control between 1 ~ 5MPa, the vacuum degree is controlled at about 0.05MPa, add 0.5kg4,6-di-tert-butylphenyl phosphate sodium and 0.1kg oleamide into the first side feeder, in the twin-screw shear After fully mixing, plasticizing and dispersing under the action, enter the second metering section, add 0.5kg of organically activated organic talcum powder of about 10,000 meshes into the second side feeder, and fully mix, melt, and Dispersion, so that the ordered structure of the nano-layered organic activated talc powder is completely destroyed, and it is evenly dispersed in the polymer matrix to obtain a polylactic acid rice composite material with transparency, high temperature resistance, and high mechanical properties.

Embodiment 2

[0043] Take 100kg undried polylactic acid, 0.5kgThemstab TM After the S220 is mixed evenly, put it into the feeder of the co-rotating twin-screw extruder, turn on the heated co-rotating twin-screw extruder, control the melt pressure between 1 and 5 MPa, and control the vacuum at 0.08 At about MPa, add 1kg dimer metaphosphate and 0.2kg stearamide into the first side feeder, fully mix, plasticize and disperse under the shearing action of the twin-screw, and then enter the second metering section. Add 1 kg of organic activated montmorillonite of about 10,000 meshes into the side feeder, fully mix, melt and disperse in the compression section again, so that the ordered structure of nano-layered organic activated montmorillonite is completely destroyed and uniform Dispersed in the polymer matrix, a polylactic acid composite material with transparency, high temperature resistance and high mechanical properties can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com