Laser anti-fake paint, preparation method thereof, and laser transfer membrane and preparation method thereof

A laser anti-counterfeiting and laser transfer technology, applied in coating, sputtering, metal material coating processes, etc., can solve the problems of producer health threats, consumer threats, strong and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a preparation method of the laser anti-counterfeiting coating described in the above technical solution, comprising the following steps:

[0036] Ethyl acetate, n-propyl acetate, propylene glycol methyl ether, butyl acetate, cellulose compound and acrylate homopolymer are mixed and heated to obtain a laser anti-counterfeiting coating.

[0037] In the present invention, the type, consumption and source of said ethyl acetate, n-propyl acetate, propylene glycol methyl ether, butyl acetate, cellulosic compound and acrylate homopolymer are the same as those of ethyl acetate, The types, amounts and sources of n-propyl acetate, propylene glycol methyl ether, butyl acetate, cellulosic compounds and acrylate homopolymers are the same and will not be repeated here.

[0038] In the present invention, the heating method preferably adopts circulating water heating of coiled pipelines. The present invention can not only reduce energy consumption and re...

Embodiment 1

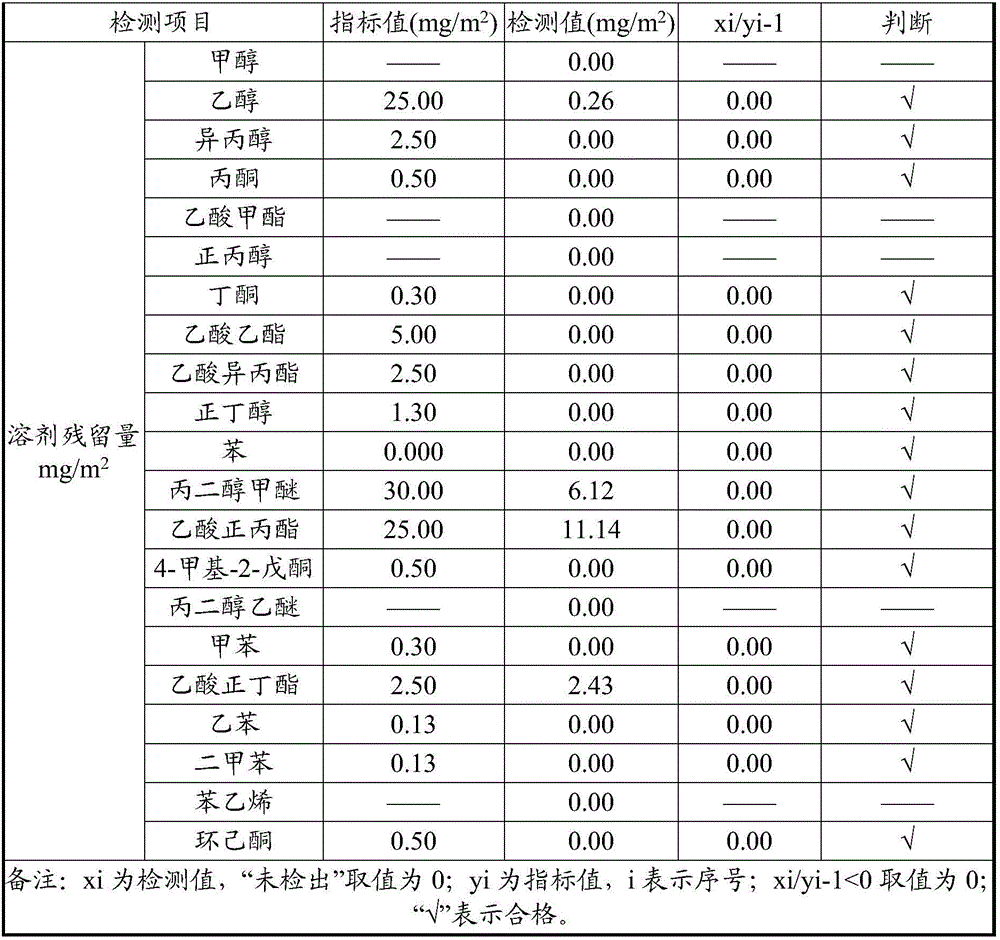

[0058] 40kg ethyl acetate, 20kg n-propyl acetate, 3kg propylene glycol methyl ether, 1kg butyl acetate, 10kg acetate-propionate cellulose and 12kg polymethyl methacrylate homopolymer were mixed, the acetate-propionate cellulose The softening point of polymethyl methacrylate is 155-165°C, and the softening point of polymethyl methacrylate is 160°C; the circulating hot water in the coiled pipe is used to heat the wall of the container, so that the temperature of the paint is kept at 45°C, and the speed of the mixer is 1400r / min. The stirring time is 3h, and the laser anti-counterfeiting coating is obtained;

[0059] The viscosity of described laser anti-counterfeit coating is to be coated with 3# cup 18s;

[0060] Coat the above-mentioned paint on the PET base film at a machine speed of 110m / min, and then dry it in an oven at 75°C, 105°C, 135°C, 120°C and 110°C, and the dry coating amount of the paint is 1.2 g / m 2 Carry out molding after drying, the temperature of molding is 1...

Embodiment 2

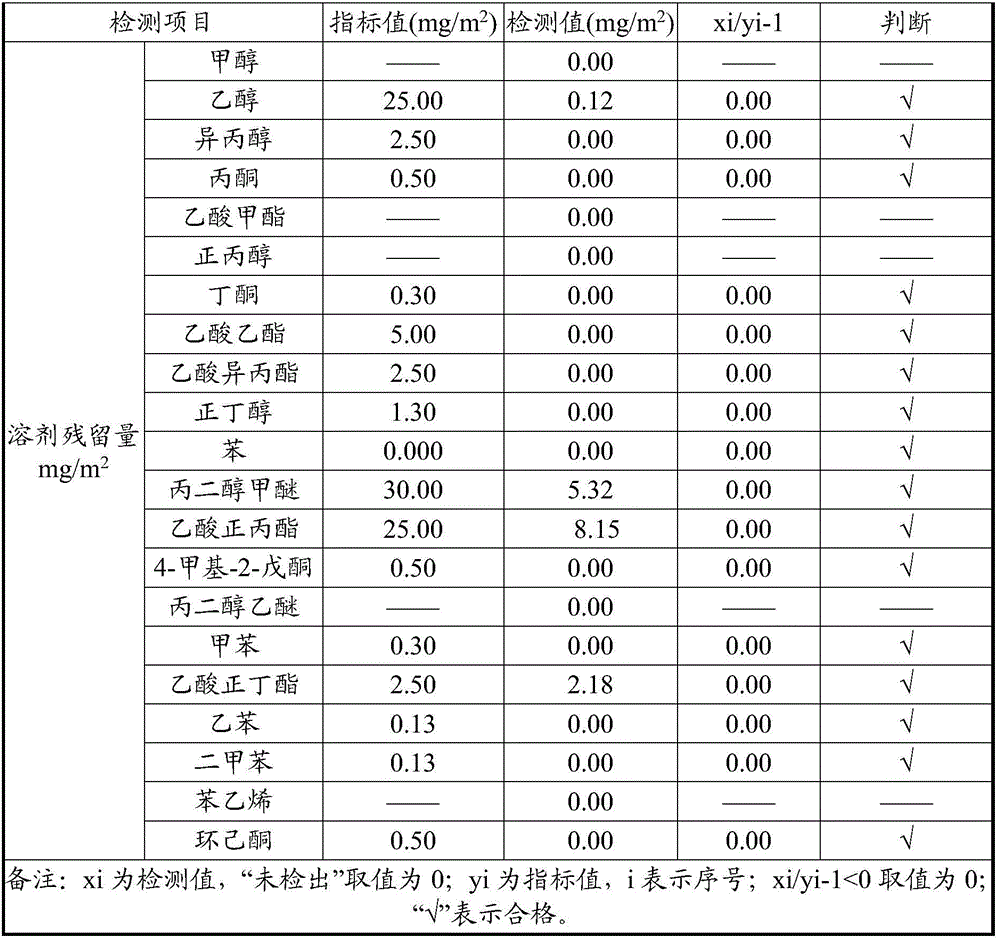

[0067] 45kg of ethyl acetate, 23kg of n-propyl acetate, 5kg of propylene glycol methyl ether, 2kg of butyl acetate, 8kg of cellulose acetate-butyrate and 10kg of polymethyl methacrylate homopolymer are mixed, and the cellulose acetate-butyrate The softening point of polymethyl methacrylate is 170-180°C, and the softening point of polymethyl methacrylate is 178°C; the circulating hot water of the coiled pipe is used to heat the wall of the container, so that the temperature of the paint is kept at 43°C, and the speed of the mixer is 1500r / min. The stirring time is 2.5h to obtain the laser anti-counterfeiting coating;

[0068] The viscosity of described laser anti-counterfeiting coating is to be coated with 3# cup 20s;

[0069] Coat the above-mentioned paint on the PET base film at a machine speed of 100m / min, and then dry it in an oven at 73°C, 109°C, 137°C, 122°C and 113°C, and the dry coating amount of the paint is 1.15 g / m 2 Carry out molding after drying, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com