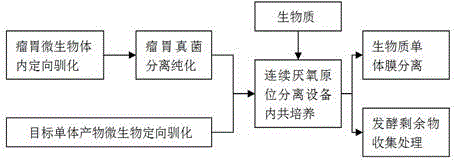

System for preparing biomass monomer through microbial coculture

A co-cultivation and biomass technology, applied in the field of biomass monomer preparation system, can solve the problems of high energy consumption, low fermentation efficiency, continuous fermentation, etc., and achieve the effect of improving efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Select goats as ruminant animals, select the biomass to be used as the carbon source after straw separation and treatment, feed the experimental animals, gradually reduce the addition of concentrated feed, and feed the prepared co-cultivation of ethanol-producing microorganisms, which can use five-carbon sugar and Six-carbon sugar Candida, fed to experimental animals for one month. Absorb the rumen content by using negative pressure gastric tube method, anaerobically roll the tube, purify goat rumen microorganisms, and cultivate them in an anaerobic incubator. After culturing for a period of time, gradually add ethanol-producing microbial metabolites to the medium for co-cultivation direction acclimatization Cultivation, sent to a small continuous culture and membrane separation device for rumen microbial amplification culture, the purified rumen microbial fiber decomposing fungi include Caecomyes single-center thallus, single-flagellate zoospores, spherical, branched rh...

Embodiment 2

[0023]Select ruminant dairy cows, select the biomass to be used as the carbon source after straw separation and treatment, feed the experimental animals, gradually reduce the addition of concentrated feed, and add at the same time to prepare ethanol-producing microorganisms for co-cultivation, which can use five carbons Candida of sugars and six-carbon sugars, fed to experimental animals for more than one month. Absorb the rumen content by negative pressure gastric tube method, anaerobically roll the tube, purify the rumen microorganisms of cows, and cultivate them in an anaerobic incubator. After a period of cultivation, gradually add ethanol-producing microbial metabolites to the medium for co-cultivation direction acclimatization Cultivated, sent to a small continuous culture and membrane separation device for enlarged culture of rumen microorganisms, and purified rumen microorganisms Ruminococcus. Rumen microorganisms are put into medium-sized anaerobic continuous culture ...

Embodiment 3

[0025] Select ruminant yellow cattle, select the biomass to be used as the carbon source after straw separation and treatment, feed the experimental animals, gradually reduce the addition of concentrated feed, and feed the prepared co-culture ethanol-producing microorganisms, which can use five-carbon sugar and Six-carbon sugar ethanol-producing bacteria, fed to experimental animals for more than one month. Absorb the rumen content by negative pressure gastric tube method, anaerobically roll the tube, purify cattle rumen microorganisms, and cultivate them in an anaerobic incubator. After culturing for a period of time, gradually add ethanol-producing microbial metabolites to the medium for co-cultivation direction acclimatization Culture, sent to small continuous culture and membrane separation device for rumen microorganism amplification culture, purified rumen microorganism Neocallimastix single-center bacteria, multi-flagellated zoospores, rich silky rhizoids N.frontalis, N....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com