Preparation method and device of in situ aluminum matrix composite

An aluminum-based composite material, in-situ technology, applied in the field of aluminum-based composite materials, can solve problems such as uneven distribution of composite particles, limited effective depth of melt, and difficulty in meeting production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

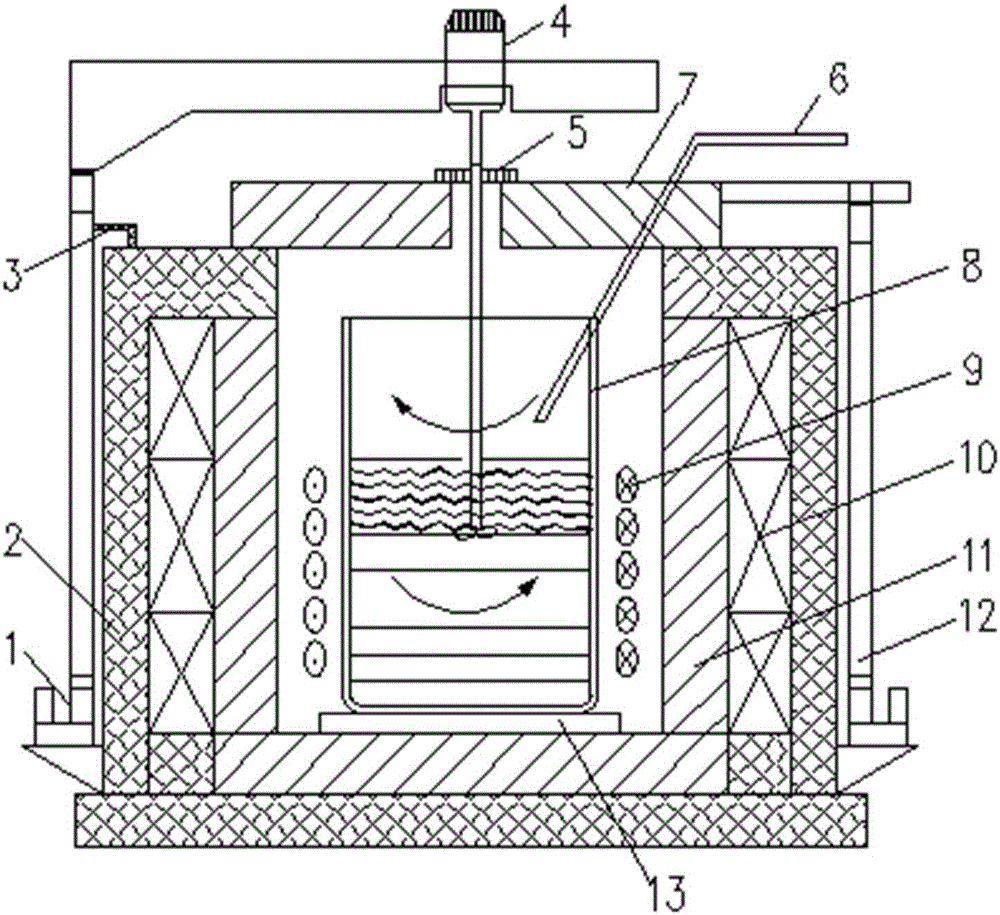

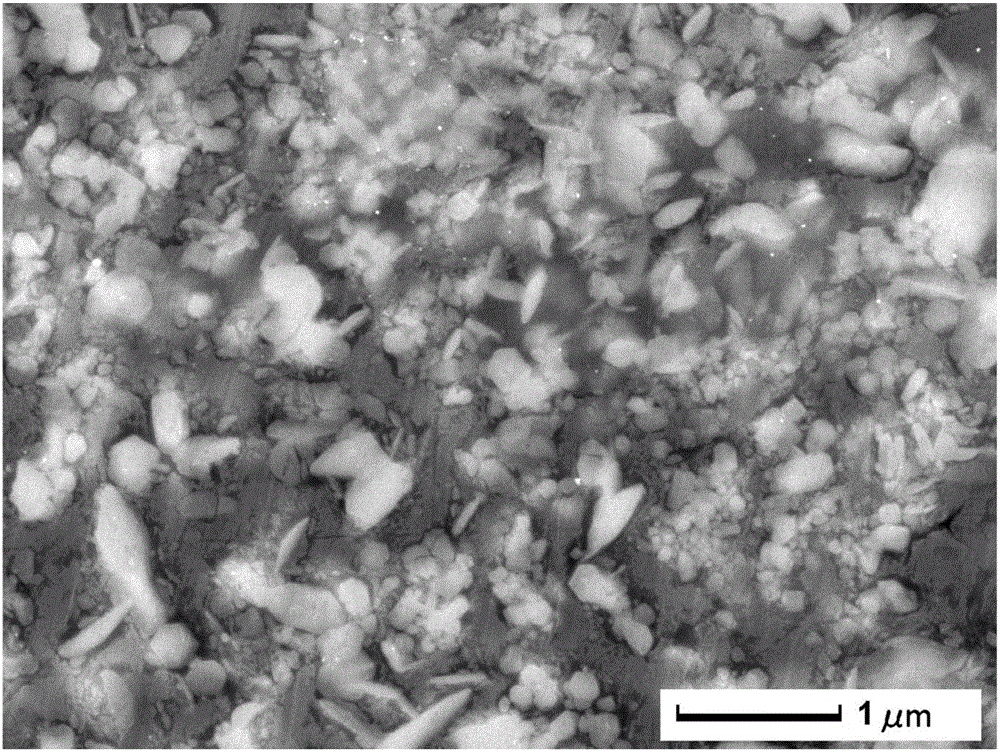

[0024] with K 2 ZrF 6 、KBF 4 As the reactant, the mixed and ground reactant powder was dried at 200°C for 2 hours for later use; the A356 aluminum alloy was placed in a graphite crucible and heated and melted with an induction coil. When the temperature reached 850°C, the dried mass was A356 The reactant powder with 20% aluminum alloy mass is pressed into the aluminum alloy melt with a bell jar; the graphite rotor is placed at the reaction interface between the aluminum alloy melt and the reactant, and the electromagnetic stirring device (frequency 10Hz) and the graphite rotor stirring device are turned on (rotating speed 150r / min), after reacting for 30min, drop the graphite rotor to the place 40mm away from the bottom of the crucible, increase the frequency of electromagnetic stirring (frequency 20Hz) and graphite rotor rotating speed (rotating speed 300r / min), after stirring for 20min, stand still, remove Gas, slag removal, when the temperature drops to 720 ° C, casting m...

Embodiment 2

[0027] Take Na 2 B 4 o 7 、K 2 ZrF 6As the reactant, the mixed and ground reactant powder was dried at 300°C for 3 hours and set aside; the A357 aluminum alloy was placed in a graphite crucible and heated and melted by an induction coil. When the temperature reached 850°C, the dried mass was The reactant powder with 10% mass of A357 aluminum alloy is pressed into the aluminum alloy melt with a bell jar; the graphite rotor is placed at the reaction interface between the aluminum alloy melt and the reactant, and the electromagnetic stirring device (frequency 2Hz) is turned on to stir with the graphite rotor device (rotating speed 50r / min), after reacting for 30min, place the graphite rotor at a distance of 40mm from the bottom of the crucible, increase the frequency of electromagnetic stirring (frequency 10Hz) and the rotating speed of the graphite rotor (rotating speed 150r / min), after stirring for 20min, let stand, After degassing and slag removal, when the temperature drop...

Embodiment 3

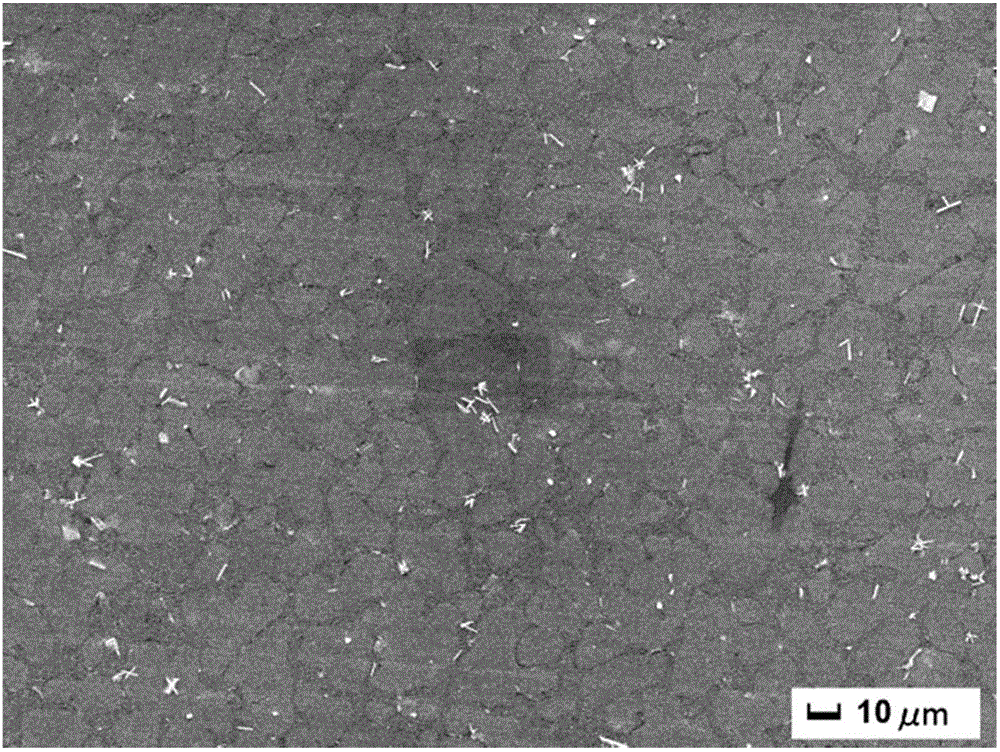

[0030] with K 2 ZrF 6 and KBF 4 For the reactant, according to generate 3wt.% nanometer ZrB 2 The particles are chemically proportioned, and the mixed and ground reactant powder is dried at 200°C for 3 hours for later use; the 6063 aluminum alloy is placed in a graphite crucible and heated and melted by an induction coil. When the temperature reaches 850°C, the dried The reactant powder whose mass is 20% of the 6063Al alloy mass is pressed into the aluminum alloy melt with a bell jar. Place the graphite rotor at the reaction interface between the aluminum alloy melt and the reactant, turn on the electromagnetic stirring device (frequency 6Hz) and the graphite rotor stirring device (rotational speed 100r / min), and after reacting for 30min, place the graphite rotor at a distance of 40mm from the bottom of the crucible At the place, increase the electromagnetic stirring frequency (frequency 15Hz) and the graphite rotor speed (rotation speed 250r / min), stir for 20 minutes, let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com