A kind of alticrn high temperature wear-resistant coating and preparation method thereof

A high-temperature wear-resistant and wear-resistant layer technology, used in coatings, metal material coating processes, vacuum evaporation plating, etc., can solve the problems of discharge stability, controllability to be improved, and low HIPIMS deposition rate. Excellent high temperature friction and wear resistance, strong bonding force and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

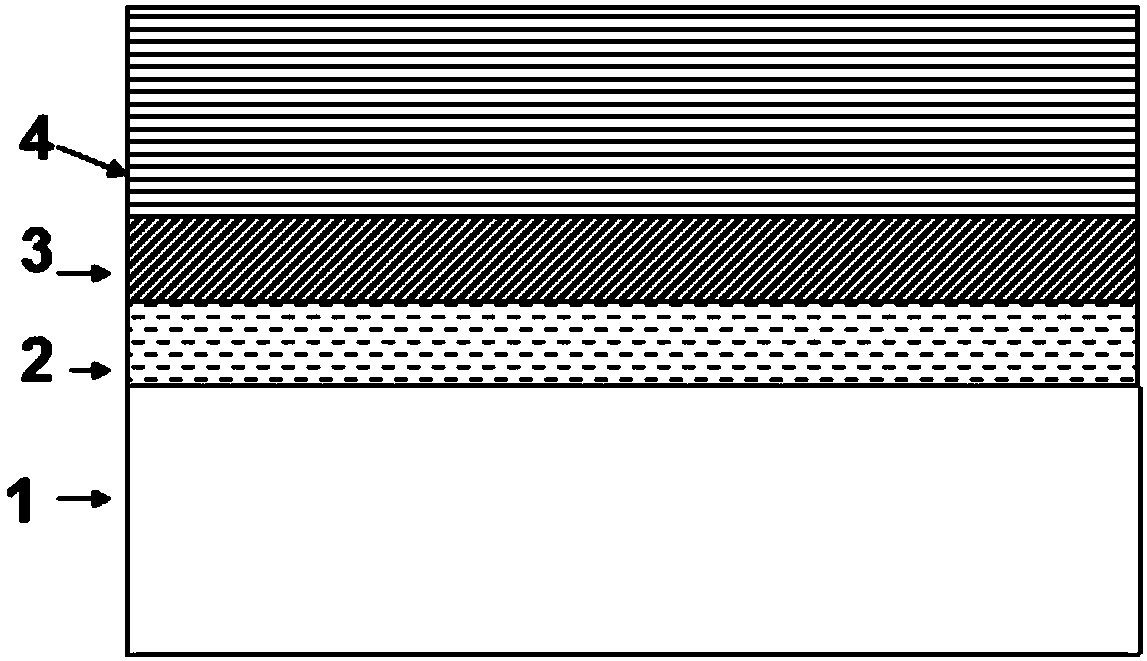

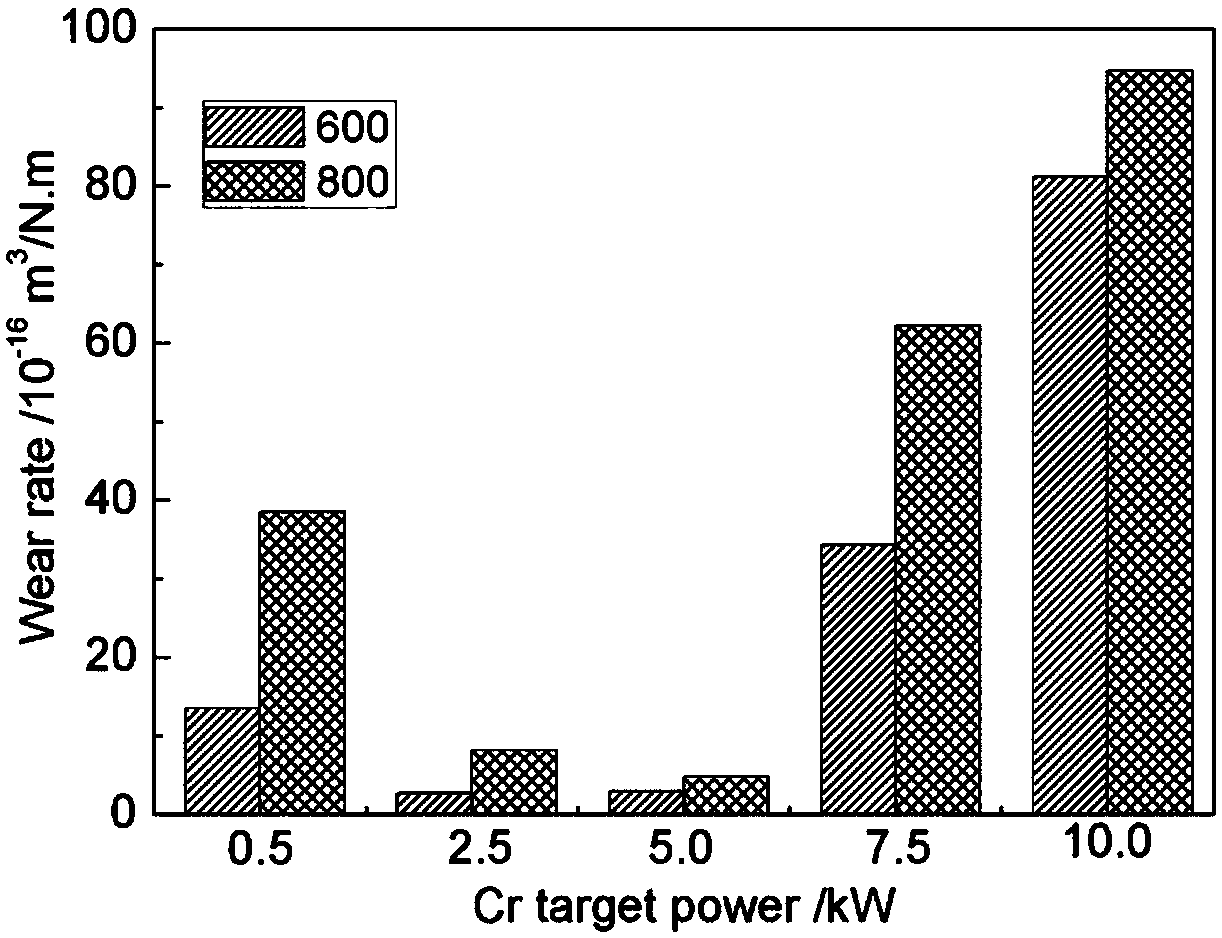

[0028] A kind of AlTiCrN high temperature wear-resistant coating, described coating is made of AlTi binding layer 2, AlTiN transition layer 3 and AlTiCrN main wear-resistant layer 4, as figure 1; The AlTi bonding layer 2 is attached to the cemented carbide 1 with a thickness of 0.1 nanometer and a composition of Al50at.% and Ti 50at.%; an AlTiN transition layer 3 is attached to the AlTi bonding layer 2 with a thickness of 0.5 microns and a composition of Al25at. %, Ti 15at.%, N 60at.%; the AlTiCrN main wear-resistant layer 4 is attached to the AlTiN transition layer 3, the thickness is 1 micron, and the composition is Al 30at.%, Ti 20at.%, Cr 1at.%, N 49at .%.

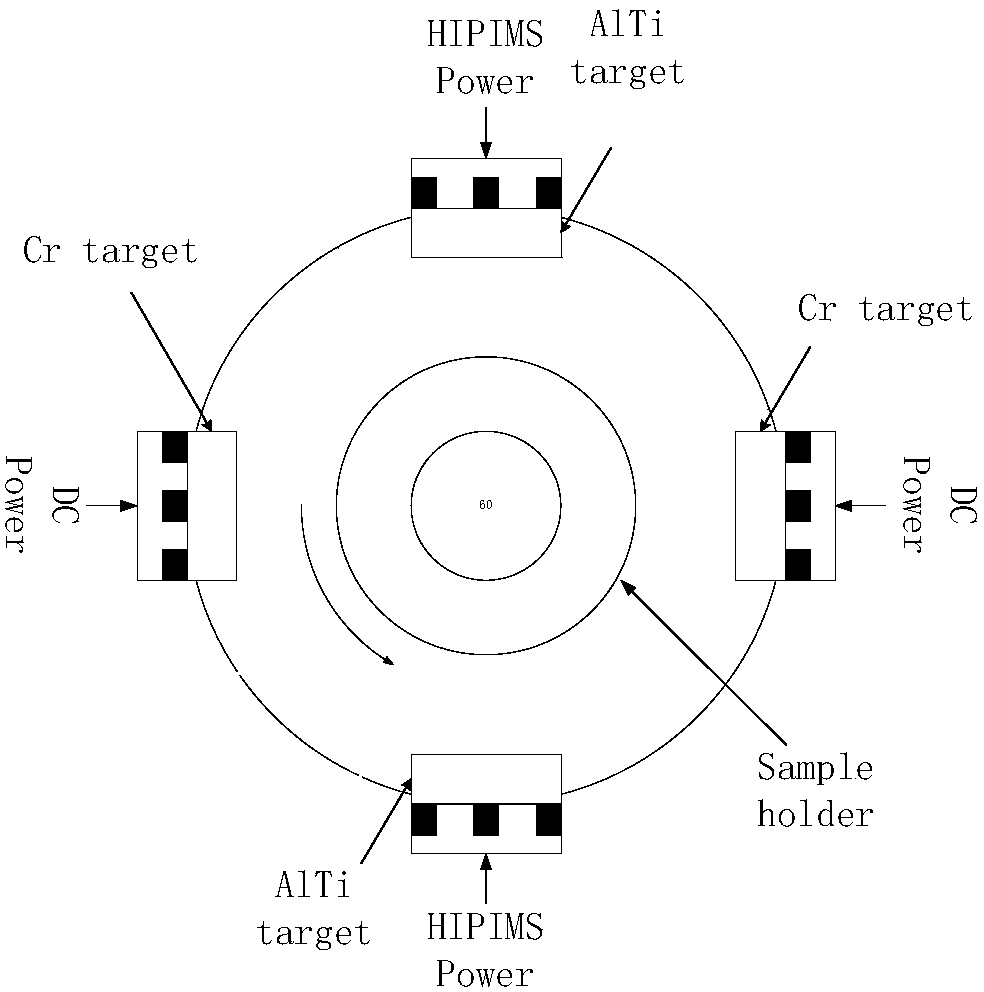

[0029] A preparation method of the AlTiCrN high-performance high-temperature wear-resistant coating is as follows:

[0030] Clamp the cleaned cemented carbide 1 on the workpiece rack and start vacuuming. When the vacuum degree reaches 1×10 ~3 At Pa, start heating and degassing, and the temperature is controlled at 30...

Embodiment 2

[0033] A kind of AlTiCrN high temperature wear-resistant coating, described coating is made of AlTi binding layer 2, AlTiN transition layer 3 and AlTiCrN main wear-resistant layer 4, as figure 1 ; The AlTi bonding layer 2 is attached to the cemented carbide 1 with a thickness of 0.5 nanometers and a composition of Al60at.% and Ti 40at.%; an AlTiN transition layer 3 is attached to the AlTi bonding layer 2 with a thickness of 1 micron and a composition of Al30at. %, Ti 20at.%, N 50at.%; the AlTiCrN main wear-resistant layer 4 is attached to the AlTiN transition layer 3, the thickness is 2 microns, and the composition is Al 16at.%, Ti 14at.%, Cr 10at.%, N 60at .%.

[0034] A preparation method of the AlTiCrN high-performance high-temperature wear-resistant coating is as follows:

[0035] Clamp the cleaned cemented carbide 1 on the workpiece rack and start vacuuming. When the vacuum reaches 3×10 ~3 At Pa, start heating and degassing, and the temperature is controlled at 400°C. ...

Embodiment 3

[0038] A kind of AlTiCrN high temperature wear-resistant coating, described coating is made of AlTi binding layer 2, AlTiN transition layer 3 and AlTiCrN main wear-resistant layer 4, as figure 2 ; The AlTi bonding layer 2 is attached to the cemented carbide 1, the thickness is 1 micron, and the composition is Al 67 at.%, Ti 33 at. %; the AlTiN transition layer 3 is attached to the AlTi bonding layer 2, the thickness is 2 microns, and the composition is Al 35at.%, Ti25at.%, N 40at.%; AlTiCrN main wear-resistant layer 4 is attached to the AlTiN transition layer 3, the thickness is 3 microns, the composition is Al10at.%, Ti 10at.%, Cr 30at.%, N 50at .%.

[0039] A preparation method of the AlTiCrN high-performance high-temperature wear-resistant coating is as follows:

[0040] Clamp the cleaned cemented carbide 1 on the workpiece rack and start vacuuming. When the vacuum degree reaches 5×10 ~3 At Pa, start heating and degassing, and the temperature is controlled at 500°C. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com