Super-hydrophobic anti-ice-coagulation compound asphalt face layer structure and preparation method thereof

A technology of composite asphalt and anti-condensation ice, which is applied in the direction of on-site coagulation pavement, road repair, road, etc., can solve the problems of rare reports and unpublished super-hydrophobic materials, and improve the anti-icing and deicing performance. , Improve the use performance, the effect of good self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

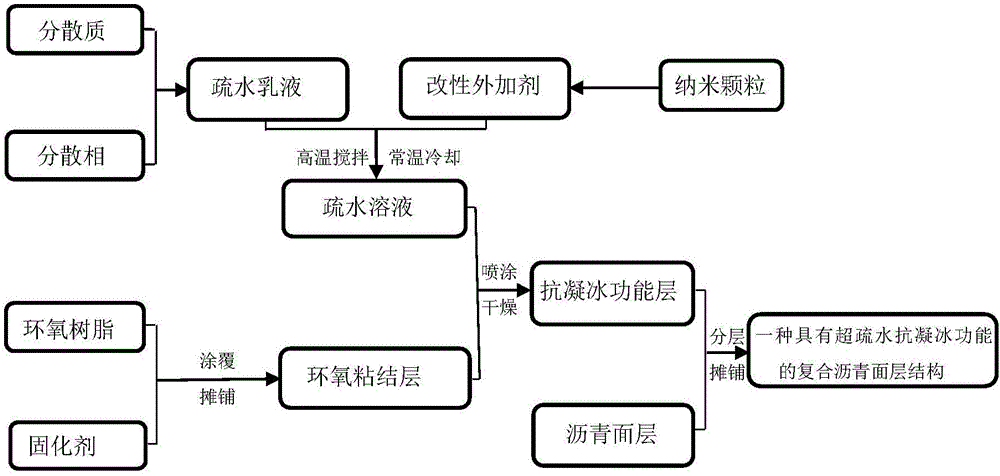

Method used

Image

Examples

Embodiment 1

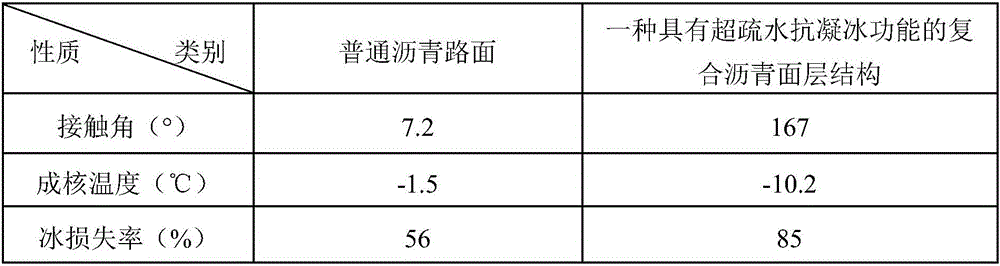

[0023] Example 1: A composite asphalt pavement structure I with superhydrophobic anti-icing function, according to the following mass ratio

[0024] Select material:

[0025] Emulsion material:

[0026] Propyltrimethoxysilane powder: 5%;

[0027] PTFE: 15%;

[0028] Deionized water: 80%.

[0029] Modified admixture:

[0030] Nano Zinc Oxide: Nano Zinc Oxide is added according to 5.0% of the mass of the emulsion material;

[0031] Epoxy bonding layer:

[0032] Epoxy resin adopts 850S epoxy resin, 20 parts;

[0033] The curing agent uses 40 parts of 593 amine curing agent and 20 parts of m-diphenylamine;

[0034] Main asphalt mixture:

[0035] The asphalt adopts road petroleum asphalt that meets the specification requirements;

[0036] Use fine-grained formula I (AC-13, I) asphalt concrete mixture;

[0037] With reference to the preparation method described in claim 8, a composite asphalt pavement structure with a superhydrophobic anti-icing function has a total thickn...

Embodiment 2

[0041] Example 2: A composite asphalt pavement structure I with superhydrophobic anti-icing function, according to the following mass ratio

[0042] Select material:

[0043] Emulsion material:

[0044] Propyltrimethoxysilane powder: 5%;

[0045] PTFE: 10%;

[0046] Deionized water: 85%.

[0047] Modified admixture:

[0048] Nano Zinc Oxide: Nano Zinc Oxide is added according to 5.0% of the mass of the emulsion material;

[0049] Epoxy bonding layer:

[0050] Epoxy resin adopts 850S epoxy resin, 20 parts;

[0051] The curing agent uses 40 parts of 593 amine curing agent and 20 parts of m-diphenylamine;

[0052] Main asphalt mixture:

[0053] The asphalt adopts road petroleum asphalt that meets the specification requirements;

[0054] Use fine-grained formula I (AC-13, I) asphalt concrete mixture;

[0055] With reference to the preparation method described in claim 8, a composite asphalt pavement structure with a superhydrophobic anti-icing function has a total thicknes...

Embodiment 3

[0059] Example 3: A composite asphalt pavement structure I with superhydrophobic anti-icing function, according to the following mass ratio

[0060] Select material:

[0061] Emulsion material:

[0062] Propyltrimethoxysilane powder: 8%;

[0063] PTFE: 12%;

[0064] Deionized water: 80%.

[0065] Modified admixture:

[0066] Nano Zinc Oxide: Nano Zinc Oxide is added according to 5.0% of the mass of the emulsion material;

[0067] Epoxy bonding layer:

[0068] Epoxy resin adopts 850S epoxy resin, 20 parts;

[0069] The curing agent uses 40 parts of 593 amine curing agent and 20 parts of m-diphenylamine;

[0070] Main asphalt mixture:

[0071] The asphalt adopts road petroleum asphalt that meets the specification requirements;

[0072] Use fine-grained formula I (AC-13, I) asphalt concrete mixture;

[0073] With reference to the preparation method described in claim 8, a composite asphalt pavement structure with a superhydrophobic anti-icing function has a total thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com