Instant and salt-baked pig tails and preparation method thereof

A technology of pig tails and tails, applied in the field of ready-to-eat salt-baked pig tails and its preparation, to achieve the effects of high production efficiency, good quality and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

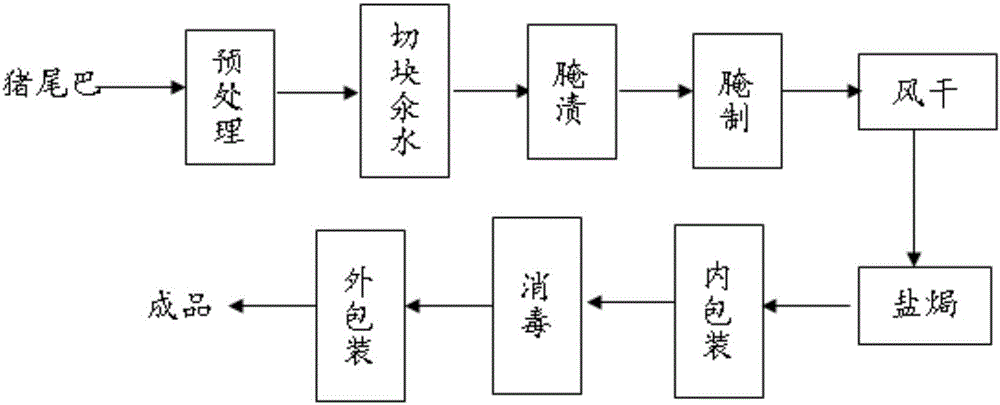

[0032] Example 1, see figure 1 :

[0033] The invention provides a kind of ready-to-eat salt-baked pig tail and a preparation method thereof, comprising the following steps:

[0034] 1) Pretreatment: Purify the pig tail;

[0035] 2) Cut into pieces and soak in water: cut the purified pig tail into pieces, put it in a boiling water pot for a while, remove and drain;

[0036] 3) Pickling: Weigh the drained pig tails and place them in a container, add a prepared salt solution with a mass concentration of 2%, submerge all the pig tails, stir evenly, the temperature is 5°C, and the pickling time is 1.5h, pick up the pig tail, wash it with clean water and drain it;

[0037] 4) Pickling: including preparation of pickling solution and pickling:

[0038] ①Preparation of extracts from Chinese herbal medicines: put star anise, peppercorns, bay leaves, cinnamon bark, fennel, nutmeg, red pepper, grass fruit, lotus seeds, coix seed and Gastrodia elata into traditional Chinese medicine e...

Embodiment 2

[0047] The invention provides a kind of ready-to-eat salt-baked pig tail and a preparation method thereof, comprising the following steps:

[0048] 1) Pretreatment: Purify the pig tail;

[0049] 2) Cut into pieces and soak in water: cut the purified pig tail into pieces, put it in a boiling water pot for a while, remove and drain;

[0050] 3) Pickling: Weigh the drained pig tails and place them in a container, add a prepared salt solution with a mass concentration of 3%, submerge all the pig tails, stir evenly, the temperature is 2°C, and the pickling time is 0.8h, pick up the pig tail, wash it with clean water and drain it;

[0051] 4) Pickling: including preparation of pickling solution and pickling:

[0052] ①Preparation of extracts from Chinese herbal medicines: put star anise, peppercorns, bay leaves, cinnamon bark, fennel, nutmeg, red pepper, grass fruit, lotus seeds, coix seed and Gastrodia elata into traditional Chinese medicine extraction tanks, and add 12 times the...

Embodiment 3

[0061] The invention provides a kind of ready-to-eat salt-baked pig tail and a preparation method thereof, comprising the following steps:

[0062] 1) Pretreatment: Purify the pig tail;

[0063] 2) Cut into pieces and soak in water: cut the purified pig tail into pieces, put it in a boiling water pot for a while, remove and drain;

[0064] 3) Pickling: Weigh the drained pig tails and place them in a container, add a prepared salt solution with a mass concentration of 2%, submerge all the pig tails, stir evenly, the temperature is 5°C, and the pickling time is 1h, pick up the pig tail, wash it with clean water and drain it;

[0065] 4) Pickling: including preparation of pickling solution and pickling:

[0066] ①Preparation of extracts from Chinese herbal medicines: put star anise, peppercorns, bay leaves, cinnamon bark, cumin, nutmeg, red pepper, grass fruit, lotus seeds, coix seed and Gastrodia elata into traditional Chinese medicine extraction tanks, and add 13 times the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com