Treatment system for removing benzenes in petrochemical industry waste gas

A technology for industrial waste gas and treatment system, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems that the treatment effect is difficult to meet the emission requirements, the operation and maintenance costs are high, and the initial investment is large. The effect of popularization and application, good treatment effect and relatively small area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

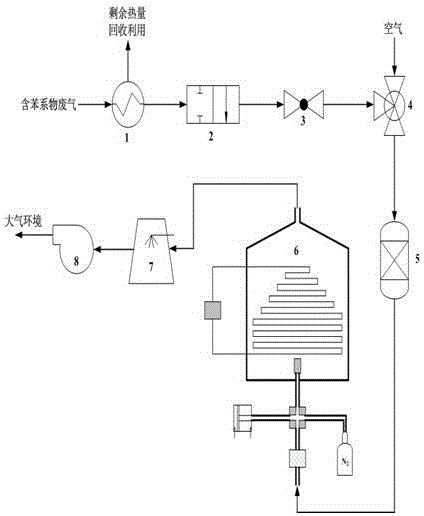

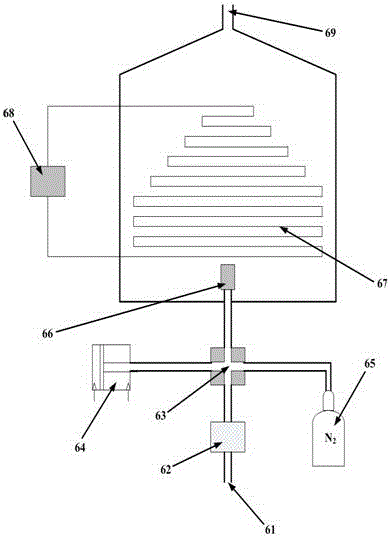

[0033] like figure 1 As shown, the treatment system for removing benzene series in petrochemical industrial waste gas includes waste heat exchanger 1, gas overheating protection device 2, thermal gas mass flow meter 3, mixed gas flow regulating valve 4, bag filter 5, Tungsten coil surface activation-ozone oxidation treatment device 6, flue gas washing and purification tower 7, induced draft fan 8, etc. Among them, the petrochemical industrial waste gas containing benzene series enters the waste heat exchanger 1 through the gas pipeline, where it undergoes heat exchange. The superheated exhaust gas is cooled and stabilized, and the obtained residual heat is available for use. The outlet of the waste heat exchanger 1 is connected to the gas overheating protection device 2 through the gas pipeline. When the temperature is still too high, the gas path can be temporarily cut off to protect the back-end processing device. The outlet of the gas overheating protection device 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com