Composite catalyst for treating antibiotic wastewater and preparing method and application thereof

A composite catalyst and antibiotic wastewater technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as biochemical pool damage, and reduce the load of wastewater systems , reduce COD value, improve the effect of sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of colloidal carbon spheres

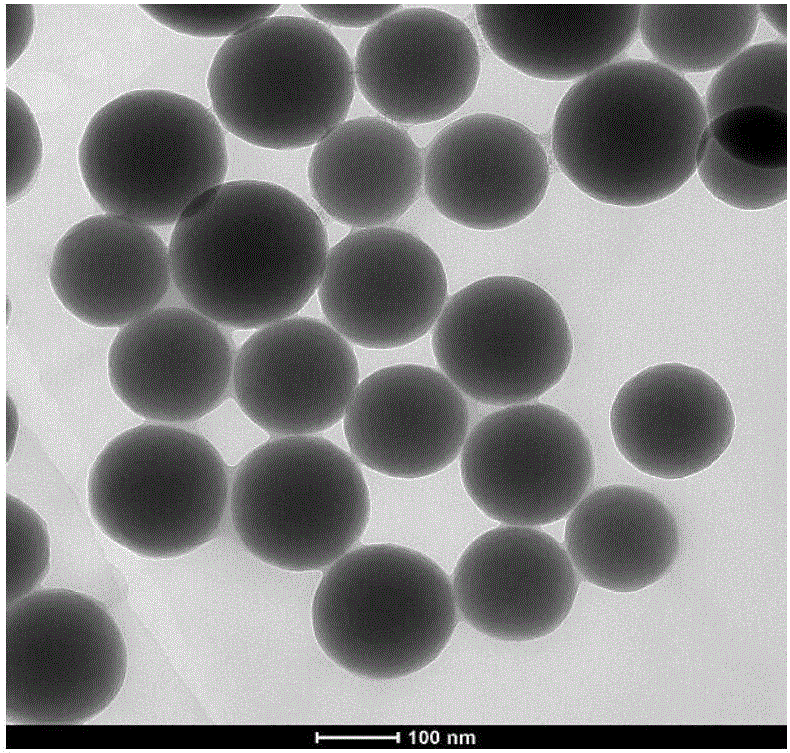

[0027] Weigh 10g of sucrose and dissolve it in 80mL of distilled water, then add 0.1mL of 0.1moL / L dilute hydrochloric acid solution, place the solution in an autoclave after ultrasonication, react at a constant temperature at 180°C for 4h, centrifuge the obtained product, and use After rinsing with deionized water and ethanol, place it in a vacuum oven at 80°C for 8 hours to obtain colloidal carbon spheres, such as figure 1 .

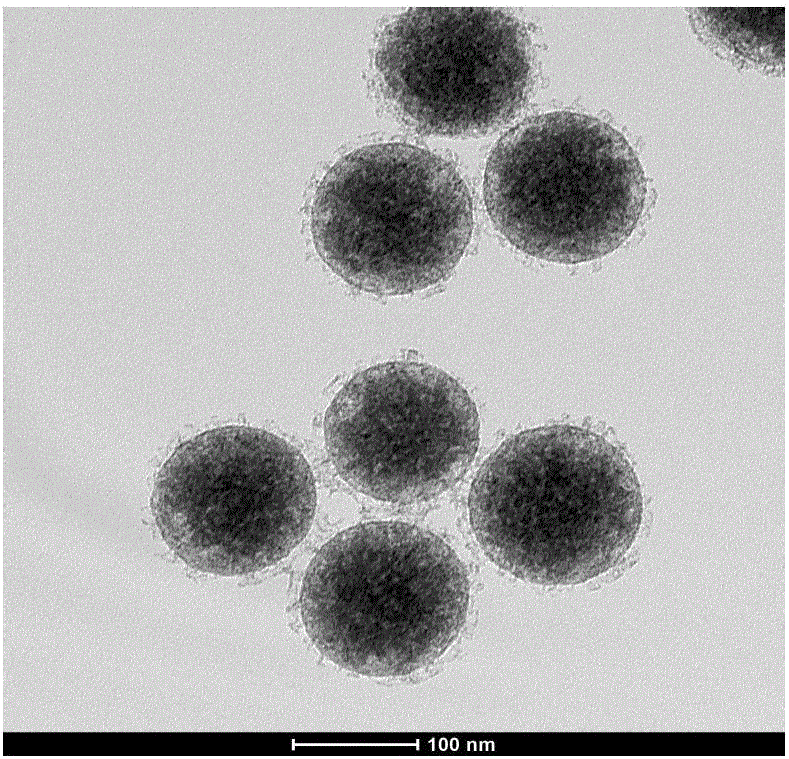

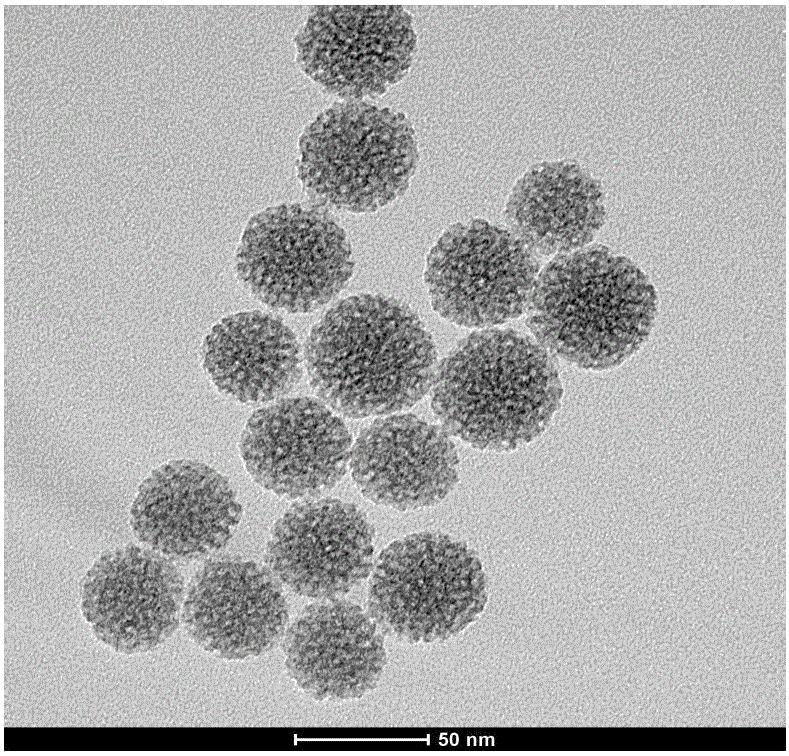

[0028] (2) Preparation of C@2%NiO / TiO 2

[0029] Take by weighing 10g colloidal carbon spheres and join in the mixed solution of 41g tetrabutyl titanate and 82g isopropanol, disperse evenly; 0.471g Ni(NO 3 ) 2 After being dissolved in water, it was added dropwise into the obtained mixed solution with a dropper, and the obtained colloid was subjected to ultrasound, standing, and vacuum drying, and then placed in a muffle furnace at 300°C for calcination for 3 hours to obtain C@2%NiO / TiO 2 ,Such...

Embodiment 2

[0035] (1) Preparation of colloidal carbon spheres

[0036] Weigh 10g of sucrose and dissolve it in 85mL of distilled water, then add 0.20mL of 0.1moL / L dilute hydrochloric acid solution, place the solution in an autoclave after ultrasonication, react at a constant temperature at 200°C for 6h, centrifuge the obtained product, and use After rinsing with deionized water and ethanol, they were placed in a vacuum oven at 90°C for 10 h to obtain colloidal carbon spheres.

[0037] (2) Preparation of C@1.5% Fe 2 o 3 / TiO 2

[0038] Take by weighing 10g colloidal carbon spheres and join in the mixed solution of 45g tetrabutyl titanate and 135g isopropanol, disperse evenly; 0.569g Fe(NO 3 ) 3 After being dissolved in water, it was added dropwise into the obtained mixed solution with a dropper, and the obtained colloid was subjected to ultrasonication, standing still, and vacuum-dried, and then placed in a muffle furnace at 350°C for calcination for 4.5 hours to obtain C@1.5%Fe 2 ...

Embodiment 3

[0043] (1) Preparation of colloidal carbon spheres

[0044] Weigh 10g of sucrose and dissolve it in 100mL of distilled water, then add 0.30mL of 0.15moL / L dilute hydrochloric acid solution, place the solution in an autoclave after ultrasonication, and react at a constant temperature of 240°C for 8h, centrifuge the obtained product, and use After rinsing with deionized water and ethanol, place them in a vacuum oven at 140°C for 12 hours to dry to obtain colloidal carbon spheres.

[0045] (2) Preparation of C@2.5%ZnO / TiO 2 spherical structure

[0046] Take by weighing 10g colloidal carbon spheres and join in the mixed solution of 50g tetrabutyl titanate and 250g isopropanol, disperse evenly; 0.583g Zn(NO 3 ) 2 After being dissolved in water, it was added dropwise to the obtained mixed solution with a dropper, and the obtained colloid was subjected to ultrasonication, standing still, and vacuum-dried, and then placed in a muffle furnace at 400°C for calcination for 6 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com