Preparation method of 5-amino-1-(2,6-dichloro-4-trifluoromethylphenyl)-3-cyanopyrazole

A technology of dichlorotrifluorotoluene and trifluoromethylphenyl is applied in the field of preparation of 5-amino-1--3-cyanopyrazole, and can solve the problem of inconvenient on-site operation, low safety factor and large amount of solid waste and other problems, to achieve the effect of improving recycling rate, reducing equipment requirements, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of 5-amino-1-(2,6-dichloro-4-trifluoromethylphenyl)-3-cyanopyrazole, comprising the following steps:

[0034] a) Using 3,4-dichlorotrifluorotoluene and dimethylamine as raw materials, using caustic soda as an acid-binding agent, and using sodium dithionite and benzyltriethylammonium chloride as catalysts to obtain 2-chloro-4- Trifluoromethyl-N,N-dimethylaniline;

[0035] b) Add sulfuryl chloride, liquid caustic soda, and azobisisobutyronitrile to the 2-chloro-4-trifluoromethyl-N,N-dimethylaniline obtained in step a) to obtain 2,6-di Chloro-4-trifluoromethylaniline;

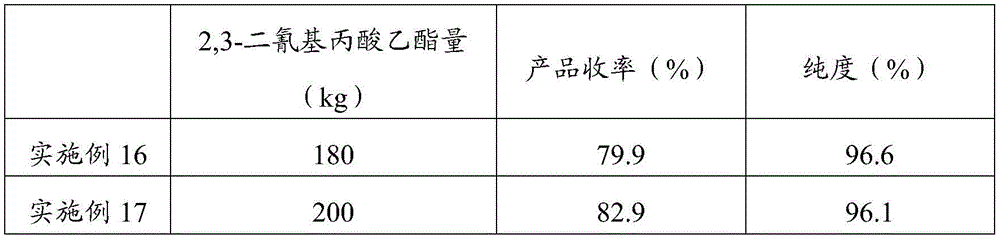

[0036] c) adding 2,6-dichloro-4-trifluoromethylaniline obtained in step b) to nitrosyl sulfate for diazotization reaction, and then adding ethyl 2,3-dicyanopropionate for diazotization Link reaction, and then carry out cyclization reaction with concentrated ammonia water in ammonia water medium, namely.

[0037] The raw materials adopted in the invention are cheap and easy to obtain,...

Embodiment 1

[0053] Under vacuum, put 1000kg of 3,4-dichlorobenzotrifluoride into the autoclave, start stirring, then put in 150kg of caustic soda, 25kg of sodium dithionite, 1.8kg of benzyltriethylammonium chloride, turn off the vacuum, and quickly put in 1800L40 % dimethylamine aqueous solution, slowly warming up to 160°C, pressure 2.0MPa, control the reaction rate of the raw material 3,4-dichlorobenzotrifluoride, the reaction is complete; after the reaction, slowly open the high pressure when the pressure is 0.4MPa The valve from the kettle to the washing kettle transfers the material to the washing kettle, and the remaining dimethylamine gas is condensed through the condenser and enters the secondary water absorption system for absorption; the material is layered in the washing kettle, and the water layer is transferred to the water absorption system as The absorption water continues to absorb the dimethylamine condensed in the next batch of material transfer process, detect the dimethy...

Embodiment 2~3

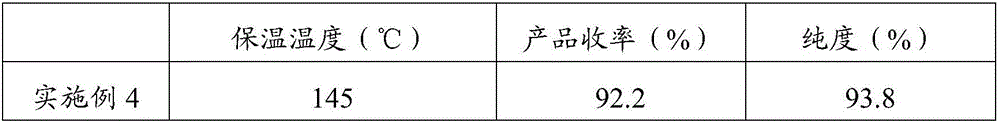

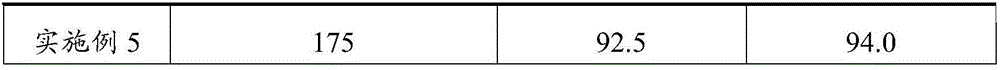

[0056] With reference to the method of Example 1, change the add-on of dimethylamine, other conditions are identical with Example 1, and the results are as shown in Table 1.

[0057] The impact of the addition amount of table 1 dimethylamine on the amine alkylation reaction

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com