Biomass carbonizing technology and system with high carbon production

A biomass charcoal, biomass raw material technology, applied in the carbonization furnace, biofuel, petroleum industry and other directions, can solve the problems of production, environmental pollution, lack of in-depth process research, etc., to reduce temperature, save energy, increase carbon production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

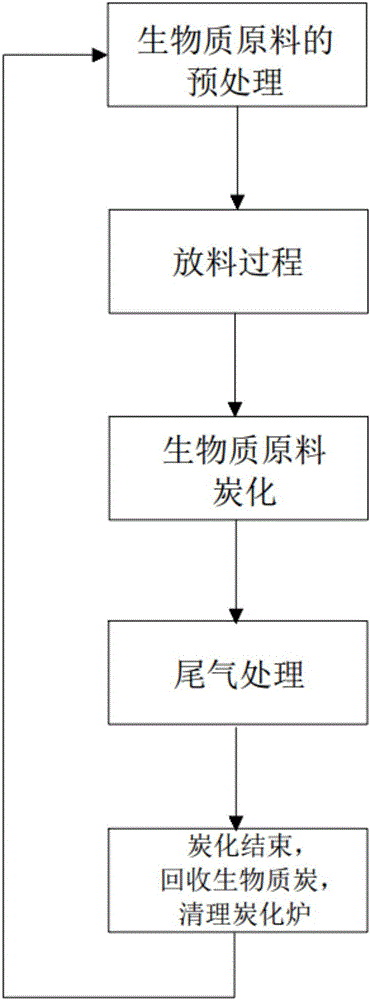

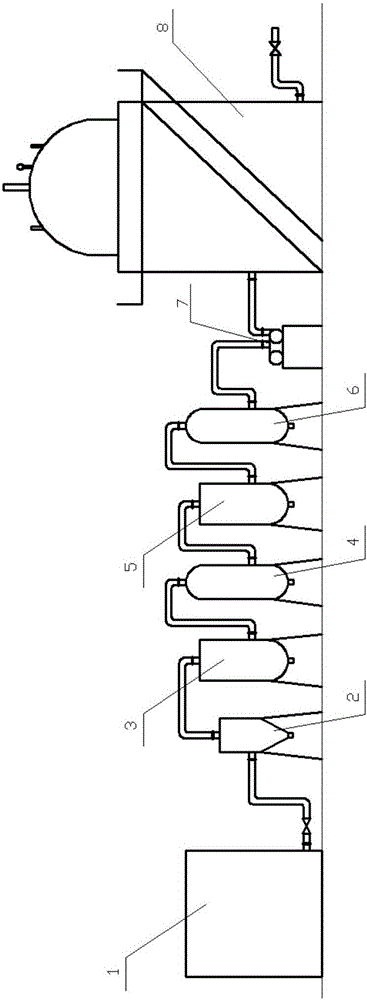

Method used

Image

Examples

Embodiment 1

[0081] The process conditions are as follows: the total amount of biomass raw materials is 3 tons, the crushed size of biomass raw materials is 5cm, the carbonization temperature is 300°C, the carbonization time is 8.5h, the induced wind speed is 11m / s, the time interval between fan cycle opening and closing is 10min, and primary condensation The condensation temperature in the process of recovering wood vinegar is 25°C, and the condensation temperature in the process of recovering wood vinegar through secondary condensation is 15°C; as a result of carbonization, 0.9 tons of biomass charcoal is produced, and the carbonization rate is 30%.

Embodiment 2

[0083] The process conditions are as follows: the total amount of biomass raw materials is 3 tons, the crushed size of biomass raw materials is 5 cm, the carbonization temperature is 350 ° C, the carbonization time is 8 hours, the induced wind speed is 11.5 m / s, the time interval between fan cycle opening and closing is 15 minutes, and the primary condensation The condensation temperature in the process of recovering wood vinegar is 25°C, and the condensation temperature in the process of recovering wood vinegar through secondary condensation is 15°C; as a result of carbonization, 0.92 tons of biomass charcoal is produced, and the carbonization rate is 30.6%.

Embodiment 3

[0085] The process conditions are as follows: the total amount of biomass raw materials is 3 tons, the crushed size of biomass raw materials is 5cm, the carbonization temperature is 400°C, the carbonization time is 7.5h, the induced wind speed is 12m / s, the time interval between fan cycle opening and closing is 20min, and primary condensation The condensation temperature in the process of recovering wood vinegar is 25°C, and the condensation temperature in the process of recovering wood vinegar through secondary condensation is 15°C; as a result of carbonization, 1.3 tons of biochar are produced, and the carbonization rate is 43.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com