A method for comprehensive recovery of zinc, iron and carbon in blast furnace gas mud

A technology for blast furnace gas sludge and iron slag, which is applied to the preparation/purification of carbon, the improvement of process efficiency, and the photographic process, etc. Economic benefits, efficient utilization, and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

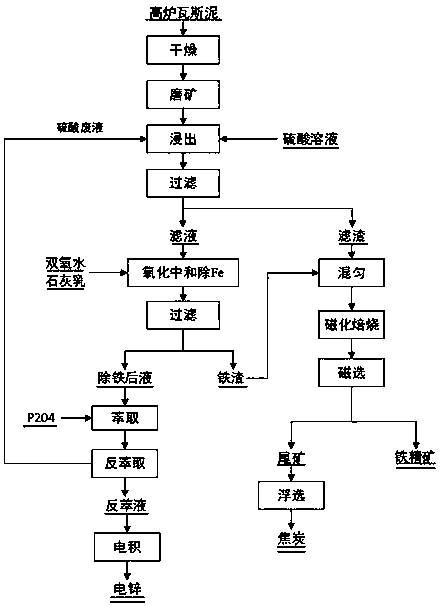

Image

Examples

Embodiment 1

[0022] In this example, a blast furnace gas mud from a steel plant in Sichuan is selected. The content of Zn in the gas mud is 9.13%, the content of TFe is 25.21%, and the content of C is 24.34%.

[0023] Table 1 Composition analysis of blast furnace gas sludge in a steel plant in Sichuan

[0024] .

[0025] The method for the comprehensive recovery of blast furnace gas sludge zinc, iron and carbon described in this embodiment specifically includes the following steps:

[0026] (1) First put the blast furnace gas mud into an electric blast drying oven to dry for 24 hours, then crush it, grind it with a mill for 10 minutes, and sieve to obtain 200-mesh blast furnace gas mud.

[0027] (2) Put the blast furnace gas marl obtained in step (1) into a beaker and put it into a constant temperature water bath. It is leached with 16% sulfuric acid solution, and filtered to obtain the filter residue and filtrate.

[0028] (3) Pour the filtrate obtained from step (2) into a beaker an...

Embodiment 2

[0036] Blast furnace gas mud from a steel plant in Yunnan was selected. The content of Zn in the blast furnace gas mud was 19.17%, the content of total iron was 22.98%, and the content of C was 15.29%.

[0037] Table 2 Composition analysis of blast furnace gas sludge in a steel plant in Yunnan

[0038] .

[0039] The method for the comprehensive recovery of blast furnace gas sludge zinc, iron and carbon described in this embodiment specifically includes the following steps:

[0040] (1) First put the blast furnace gas mud into an electric blast drying oven to dry for 48 hours, then crush it, grind it with a mill for 12 minutes, and sieve to obtain 200-mesh blast furnace gas mud powder.

[0041] (2) Put the blast furnace gas mud powder obtained in step (1) into a beaker and put it into a constant temperature water bath. It is leached with 20% sulfuric acid solution, and filtered to obtain the filter residue and filtrate.

[0042] (3) Pour the filtrate obtained from step (2...

Embodiment 3

[0050] Blast furnace gas mud from another iron and steel plant in Yunnan was selected. The content of Zn in the blast furnace gas mud was 13.44%, the content of total iron was 21.18%, and the content of C was 17.62%.

[0051] Table 3 Composition analysis of blast furnace gas sludge in a steel plant in Yunnan

[0052] .

[0053] The method for the comprehensive recovery of blast furnace gas sludge zinc, iron and carbon described in this embodiment specifically includes the following steps:

[0054] (1) First put the blast furnace gas mud into an electric blast drying oven to dry for 40 hours, then crush it, grind it with a mill for 15 minutes, and sieve to obtain 200-mesh blast furnace gas mud powder.

[0055] (2) Put the blast furnace gas mud powder obtained in step (1) into a beaker and put it into a constant temperature water bath. It is leached with 18% sulfuric acid solution, and filtered to obtain the filter residue and filtrate.

[0056] (3) Pour the filtrate obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com