High-ionic conductance full-solid-state composite cathode piece, battery comprising same and preparation method

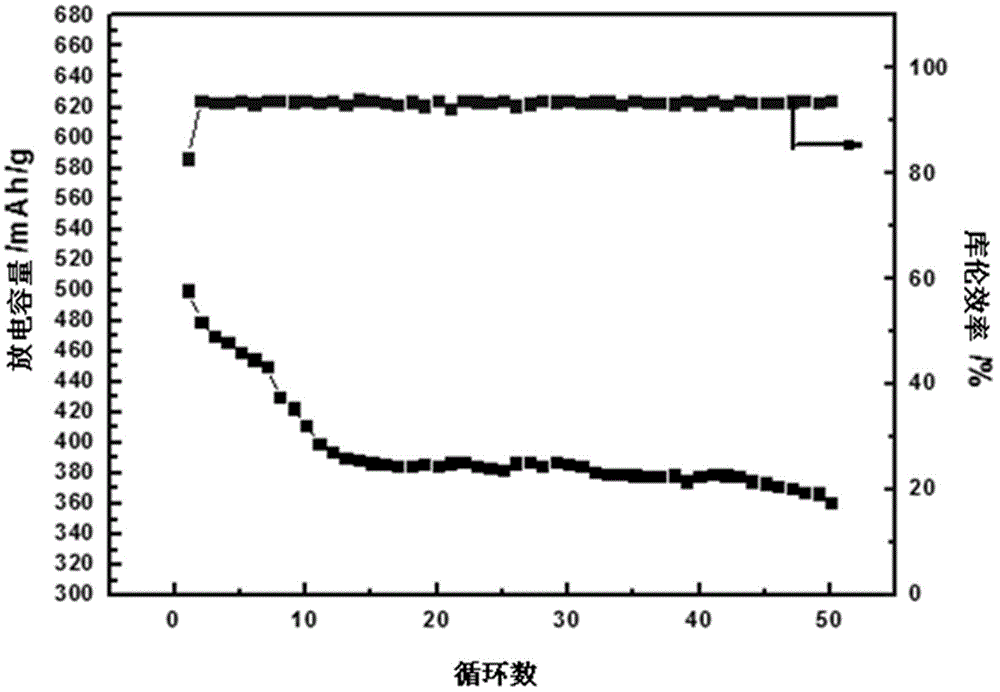

A composite positive electrode and ion conduction technology, which is applied in electrode manufacturing, electrode collector coating, non-aqueous electrolyte storage battery, etc., can solve the problems of inability to withstand the impact and extrusion of lithium-ion batteries, large interface impedance between positive electrode and solid electrolyte, and Inorganic solid electrolytes have poor flexibility and other problems, achieving excellent cycle performance and stability, shortening test time, and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An all-solid-state composite Li with high ionic conductivity 2 Preparation of S cathode sheet and preparation of composite solid electrolyte:

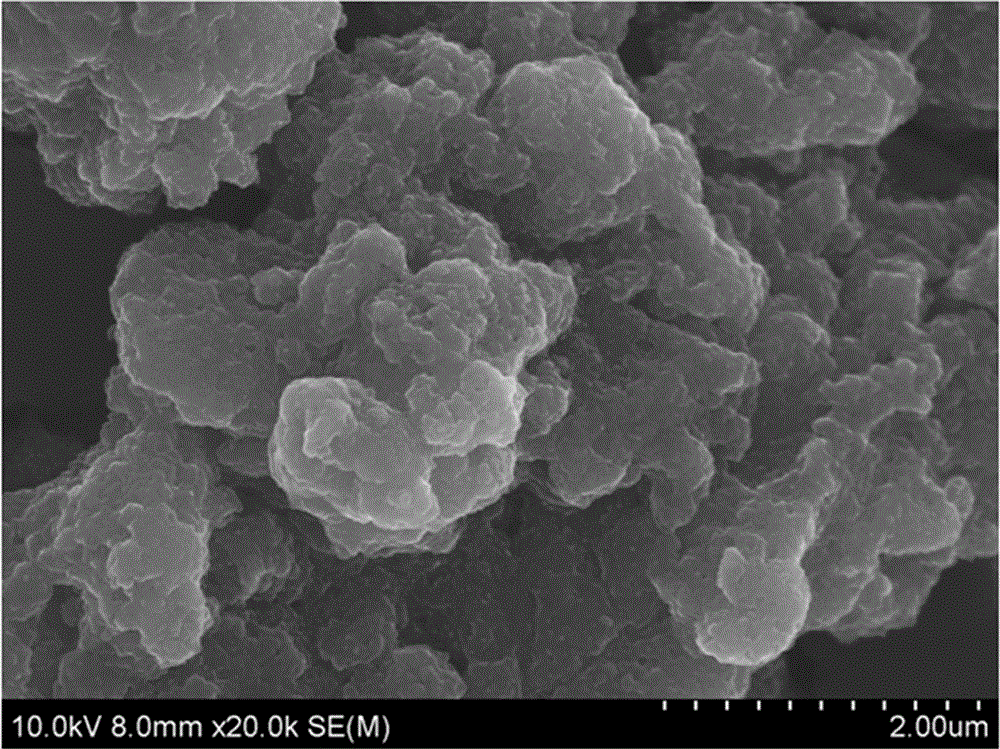

[0044] (1) A certain amount of Li with a purity of 99.99% 2 Dissolve S in the analytical alcohol, and prepare Li with a concentration of 0.5mol / L 2 S ethanol solution, fully dissolved and stirred for 1h. (2) Weigh a certain amount of carbon nanotubes (CNTs) that have been dried at 120°C in advance, and the mass ratio of CNTs: Li 2 S=20:80, slowly added to the solution in (1), stirred while adding, and finally the mixed solution was stirred slowly for 2 hours, and baked under the infrared light physiotherapy apparatus for 10 hours until completely dry to obtain CNT@Li 2 S composite active material. (3) The prepared CNT@Li 2 The S composite material is placed in a vacuum ball mill tank (glove box operation) and sealed, and then ball milled for 3 hours at 1050rpm / min with a high-energy ball mill to obtain the nanoscale composi...

Embodiment 2

[0046] An all-solid-state composite Li with high ionic conductivity 2 Preparation of S cathode sheet and preparation of composite solid electrolyte:

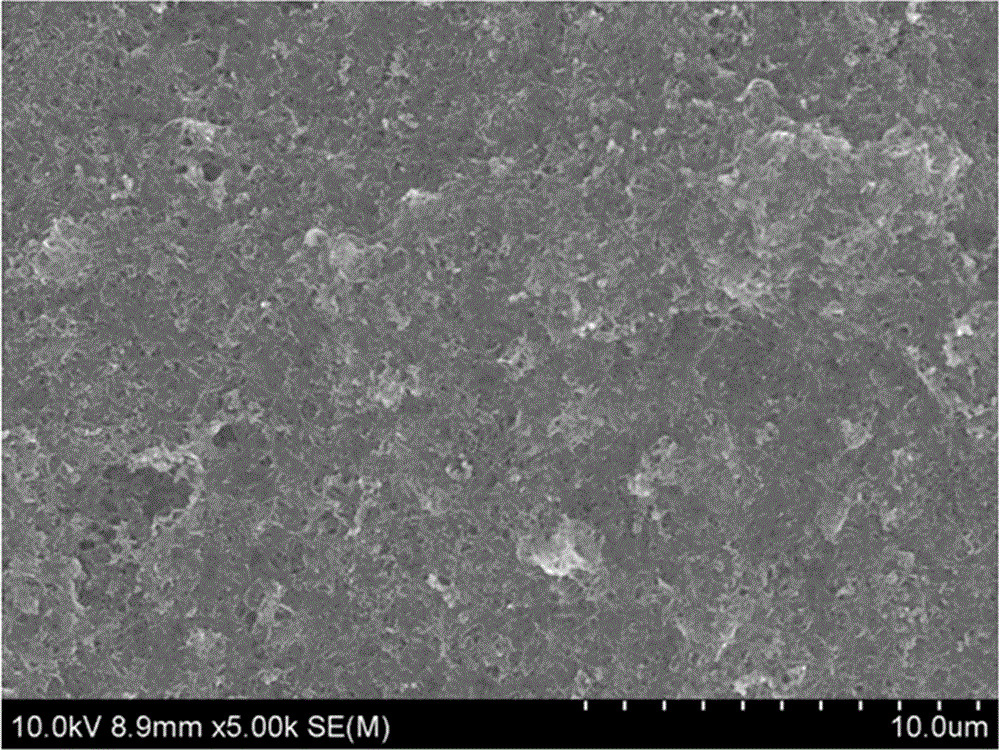

[0047] A certain amount of Li with a purity of 99.99% 2 Dissolve S in the analytical alcohol, and prepare Li with a concentration of 0.5mol / L 2 S ethanol solution, fully dissolved and stirred for 1h. (2) Weigh a certain amount of carbon nanotubes (CNTs) that have been dried at 110°C in advance, and the mass ratio of CNTs: Li 2 S=20:80, slowly added to the solution in (1), stirred while adding, and finally the mixed solution was stirred slowly for 2 hours, and baked under the infrared light physiotherapy apparatus for 10 hours until completely dry to obtain CNT@Li 2 S composite active material. (3) Final preparation of solid-state composite cathode sheet: according to the mass ratio of CNT@Li 2 S: CB (carbon black): PVDF=40:45:15 Weigh a certain mass of substances for use. Add the binder PVDF to the NMP solution and stir fo...

Embodiment 3

[0049] An all-solid-state composite Li with high ionic conductivity 2 Preparation of S cathode sheet and preparation of composite solid electrolyte:

[0050] Weigh a certain amount of Li with a purity of 99.99% 2 S and carbon nanotubes (CNTs) dried at 120°C, the mass ratio of CNT: Li 2 S=25:75. Place it in a vacuum ball mill jar and perform high-energy ball milling at 1000 rpm / min for 3 hours to obtain nanoscale composite materials. (2) Final preparation of solid-state composite cathode sheet: according to the mass ratio of Li 2 S@CNT: CB (carbon black): PVDF=40:45:15 Weigh a certain mass of substances for use. Add the binder PVDF to the NMP solution and stir for 1 hour, then add the conductive agent CB and stir for 1 hour, and finally add the active material CNT@Li 2 S was stirred together for 10 h and then coated. The positive current collector was made of Al foil. After the coating was completed, it was dried at 110 ° C for 10 h, and a high ion conductivity all-solid-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com