Novel compound and coloring photosensitive composition

A photosensitive composition and compound technology, applied in optics, filters, optical elements, etc., can solve the problems of unsatisfactory solvent resistance and heat resistance, and achieve excellent waveform controllability, solvent resistance and Excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

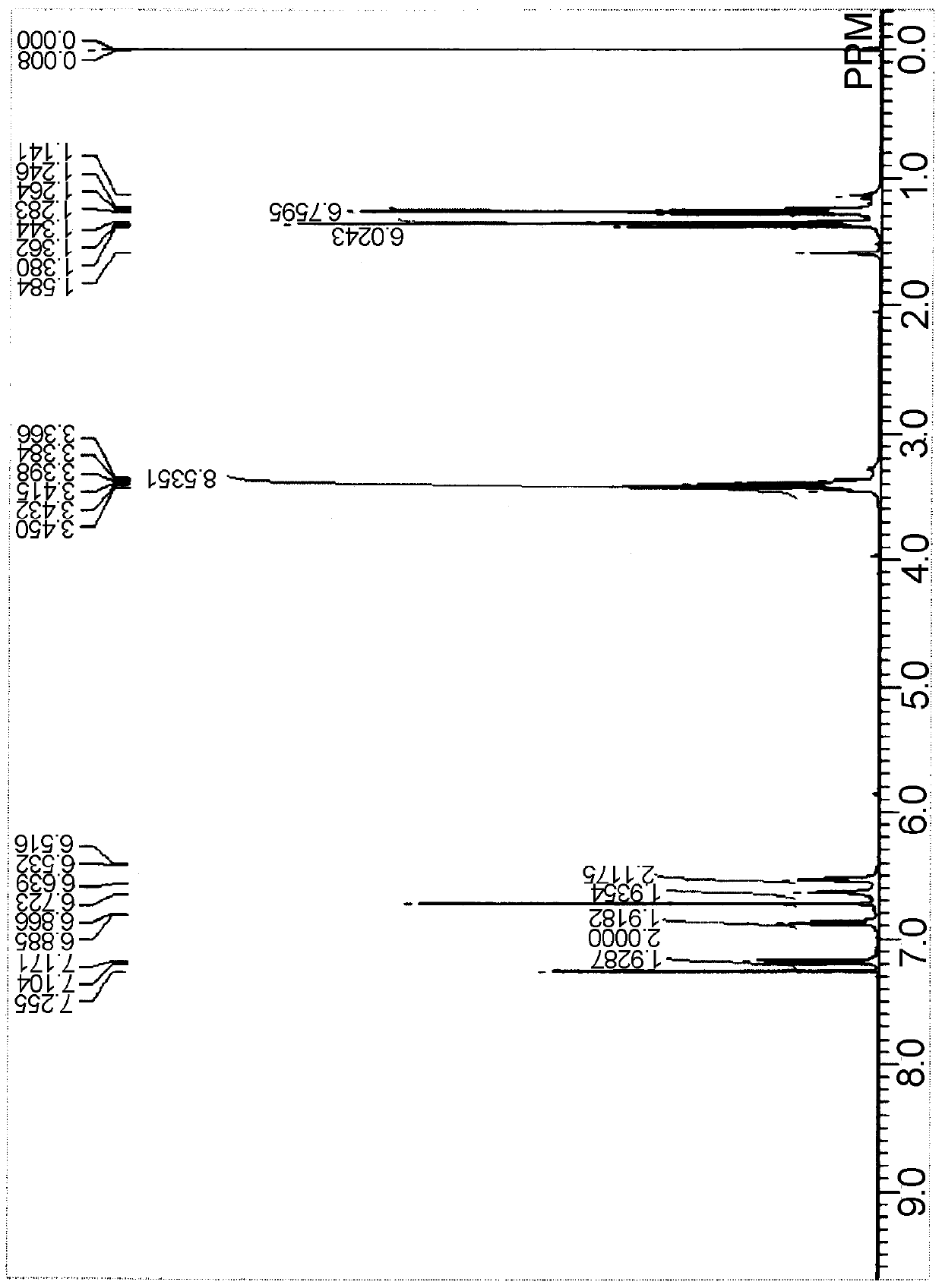

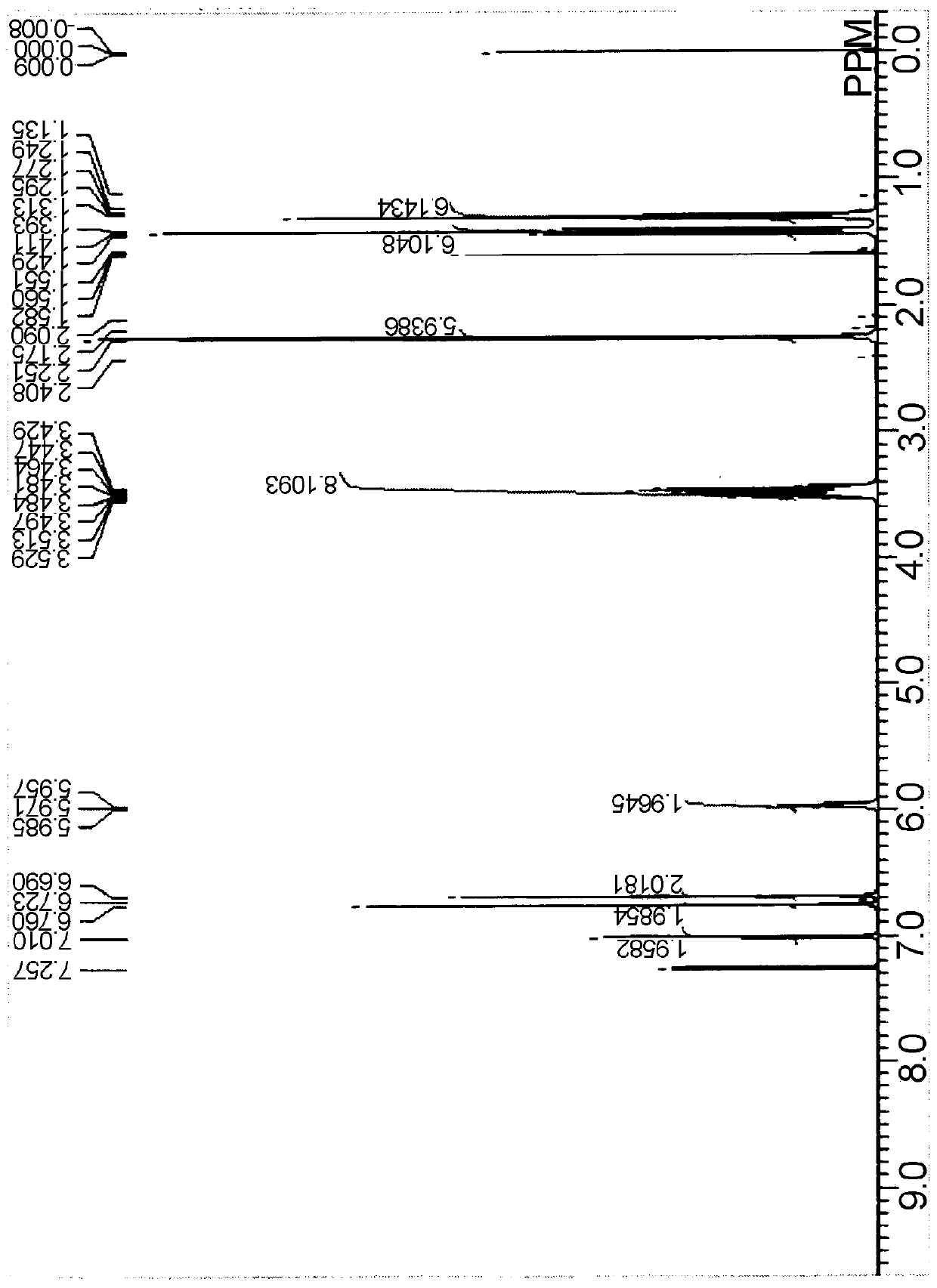

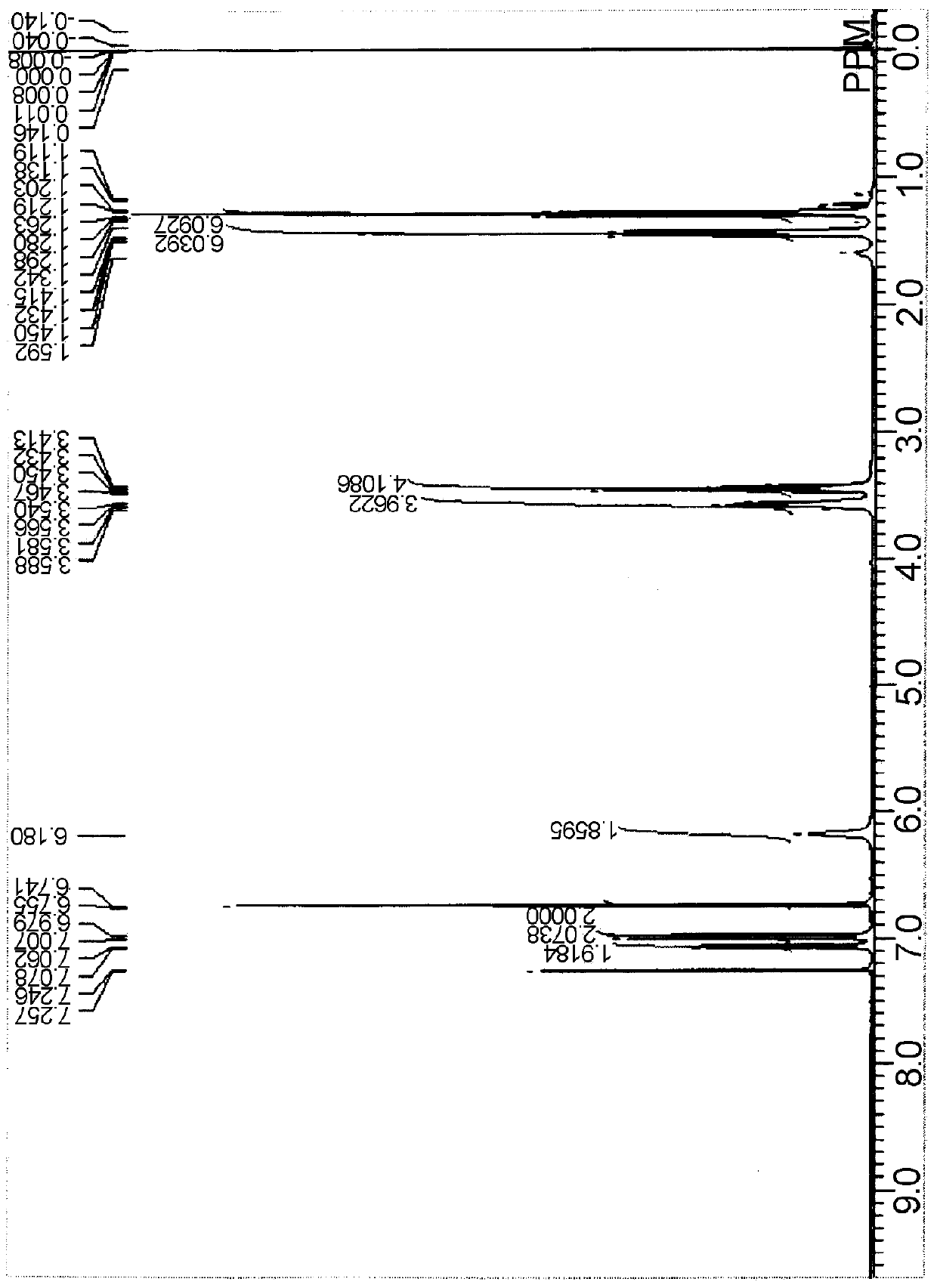

[0178] The synthesis of embodiment 1. compound No.13, No.25, No.26 and No.35

[0179]

[0180] 0.01 mol of the following compound S-1, 0.02 mol of monoethylaminophenol, and 0.03 mol of sulfuric acid were mixed, and stirred at 140° C. for 8 hours. The reaction solution was added dropwise to an aqueous sodium hydroxide solution, the organic matter was extracted with toluene, and after washing with water three times, the solvent was distilled off from the organic layer. The residue was purified by silica gel chromatography (developing solvent: chloroform) to obtain 0.005 mol of a colorless product (52% yield).

[0181] (Compound S-1)

[0182]

[0183]

[0184] 2.56 g (0.005 mol) of the colorless substance obtained in step 1, 19.75 g of water, and 3.95 g of hydrochloric acid were added, and after stirring, 9.27 g of a 35% by mass ferric chloride aqueous solution was added, and stirred at 80° C. for 8 hours. After cooling to room temperature, chloroform was added, the aque...

Embodiment 2 and comparative example 2

[0190] Example 2 and Comparative Example 2. Preparation of Colored Alkali Developable Photosensitive Composition

[0191] Preparation of Alkali Developable Photosensitive Composition

[0192] 30.33 g of ACA Z251 (manufactured by Daicel-Cytec Co., Ltd.) and 11.04 g of Aronix M-450 (manufactured by Toagosei Co., Ltd.) as (B) component, and 1.93 g of IRGACURE 907 (manufactured by BASF Co., Ltd.) as (C) component, as ( 20.08 g of PGMEA of E) component, and 0.01 g of FZ2122 (made by Toray-Dow Corning) which are other components were mixed, and it stirred until the insoluble matter disappeared, and obtained the alkali-developing photosensitive composition.

[0193] Preparation of dye solution

[0194] 0.10 g of the compounds described in Table 3 and 1.90 g of PGMEA were added as (A) component, respectively, and they were stirred and dissolved, and it was set as dye liquid No.1-No.2 and comparison dye liquid No.1-No.2.

[0195] Preparation of Colored Alkali Developable Photosens...

Embodiment 3 and comparative example 3

[0200] Example 3 and Comparative Example 3. Heat resistance evaluation by firing

[0201] Colored alkali-developable photosensitive compositions No.1 and No.2 obtained in Example 2 and comparative colored alkali-developable photosensitive compositions No.1 and No.2 obtained in Comparative Example 2 were respectively prepared at 410 rpm×7 Second conditions were applied on a glass substrate, and dried on a hot plate (90° C., 90 seconds). Gained coating film utilizes ultra-high pressure mercury lamp to expose (150mJ / cm 2 ). The coating film after exposure was baked on the condition of 230 degreeC x 30 minutes. The color difference (ΔEab*) before and after firing was investigated. The better the heat resistance, the higher the value of the color difference. The results are shown in Table 4.

[0202] Table 4

[0203] compound (dye) Color difference△Eab* Evaluation example 1-1 Compound No.25 1.74 Evaluation example 1-2 Compound No.26 1.50 Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com