Microcapsule double-aqueous-phase purification method of tobacco clove oil, and applications thereof

A clove oil and two-phase technology, which is applied in the field of preparation of cigarette flavors and fragrances, can solve the problems of eugenol deterioration and low purity, and achieve the effects of fine and soft smoke, improved purity and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

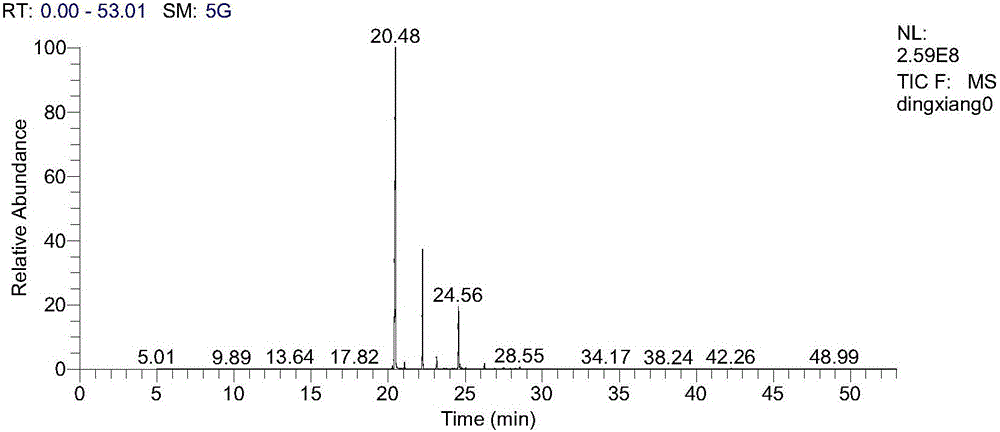

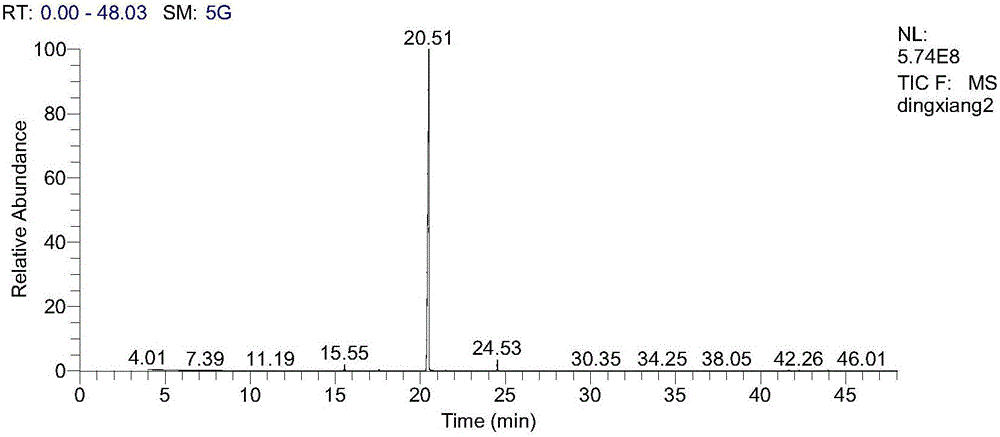

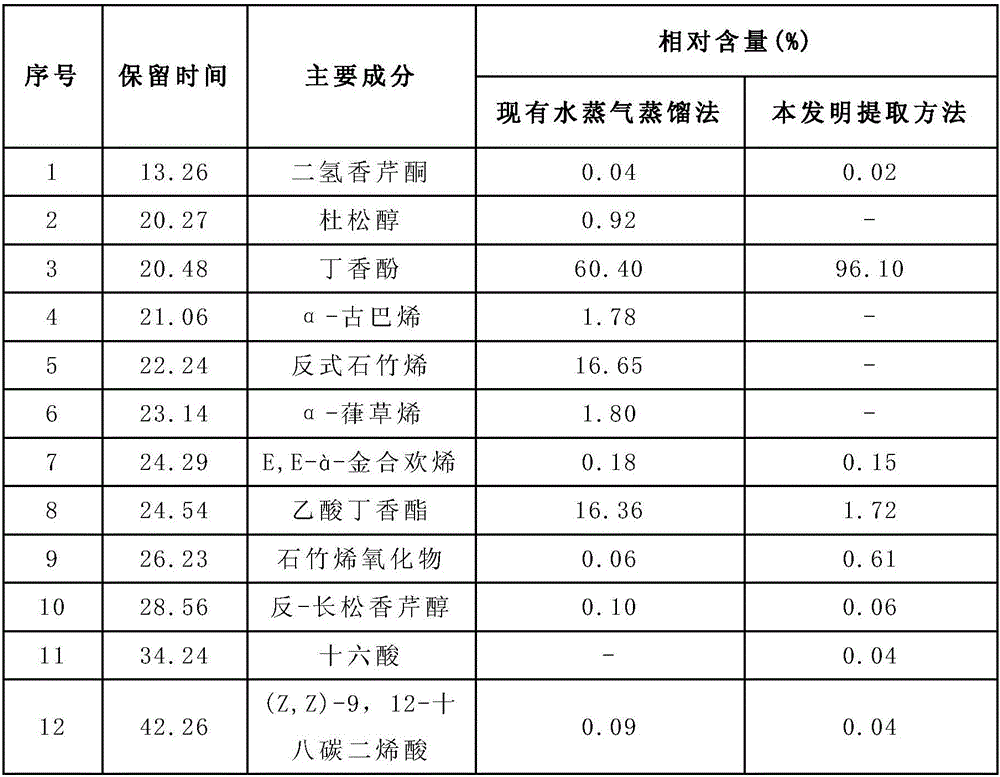

Image

Examples

Embodiment 1

[0030] Embodiment 1, a microcapsule aqueous two-phase extraction method of clove oil for tobacco is characterized in that the specific steps include:

[0031] (1) Place the dried lilac flower buds in an ultrasonic extraction device, use 45% ethanol aqueous solution as a solvent, add 15 times the extraction solvent of the lilac flower bud quality, and ultrasonicate at a temperature of 55°C and an ultrasonic frequency of 50kHz Extract for 40min to obtain clove extract;

[0032] (2) adopt 0.8 micron ceramic membrane to filter the extract, remove the clove raw material that has been extracted;

[0033] (3) Add 30% food-grade β-cyclodextrin vesicle wall material and 15% food-grade sodium sulfate to the filtered extract, and stir the mixture evenly in a constant temperature water bath at 60°C, usually for about 25 minutes ;

[0034] (4) The mixed solution stirred uniformly in the step (3) is left to stand at normal temperature for 3 hours, and the solvent layer and the dextrin mic...

Embodiment 2

[0037] Embodiment 2, a microcapsule aqueous two-phase extraction method of clove oil for tobacco, is characterized in that the specific steps include:

[0038] (1) Place the dried clove buds in an ultrasonic extraction device, use 40% ethanol aqueous solution as a solvent, add 10 times the mass of clove buds as an extraction solvent, and ultrasonicate at a temperature of 60°C and an ultrasonic frequency of 40kHz Extract for 60min to obtain clove extract;

[0039] (2) adopt 200 mesh sieves to filter the extract, remove the clove raw material that has been extracted;

[0040] (3) Add 50% food-grade β-cyclodextrin vesicle wall material and 12% food-grade sodium chloride to the filtered extract, and stir the mixture in a constant temperature water bath at 50°C for 30 minutes until uniformly mixed;

[0041] (4) The mixed solution stirred uniformly in the step (3) is left to stand at normal temperature for 3 hours, and the solvent layer and the dextrin microcapsule layer are obtain...

Embodiment 3

[0044] Embodiment 3, a microcapsule aqueous two-phase extraction method of clove oil for tobacco, is characterized in that the specific steps include:

[0045] (1) Place the dried clove buds in an ultrasonic extraction device, use 50% ethanol aqueous solution as a solvent, add 15 times the mass of clove buds as an extraction solvent, and ultrasonicate at a temperature of 40°C and an ultrasonic frequency of 70kHz Extract for 30min to obtain clove extract;

[0046] (2) Adopt disc centrifuge to filter extract, remove the clove raw material that has been extracted;

[0047] (3) Add 35% food-grade α-cyclodextrin vesicle wall material and 20% food-grade sodium hydroxide to the filtered extract, and stir the mixture in a constant temperature water bath at 30°C for 15 minutes until uniformly mixed;

[0048] (4) The mixed solution stirred uniformly in the step (3) is left to stand at normal temperature for 3 hours, and the solvent layer and the dextrin microcapsule layer are obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com