Plate strip surface scale removal device and method

A technology for descaling equipment and strips, used in workpiece surface treatment equipment, metal processing equipment, cleaning methods and appliances, etc., can solve the specific technical differences, scratches on the surface of strips, no further explanation of gas technology links and other aspects. Auxiliary equipment and other issues to achieve the effect of improving surface quality, ensuring quality and reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

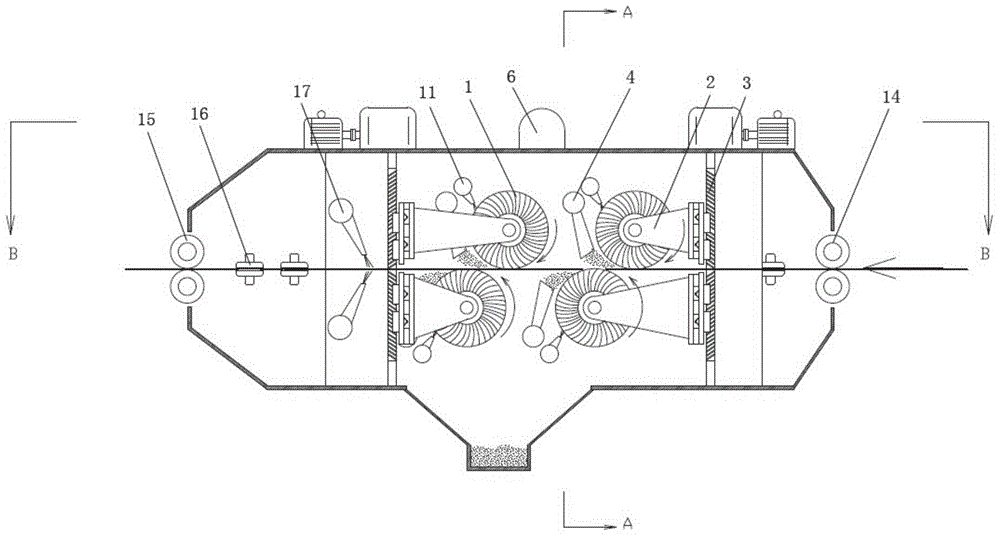

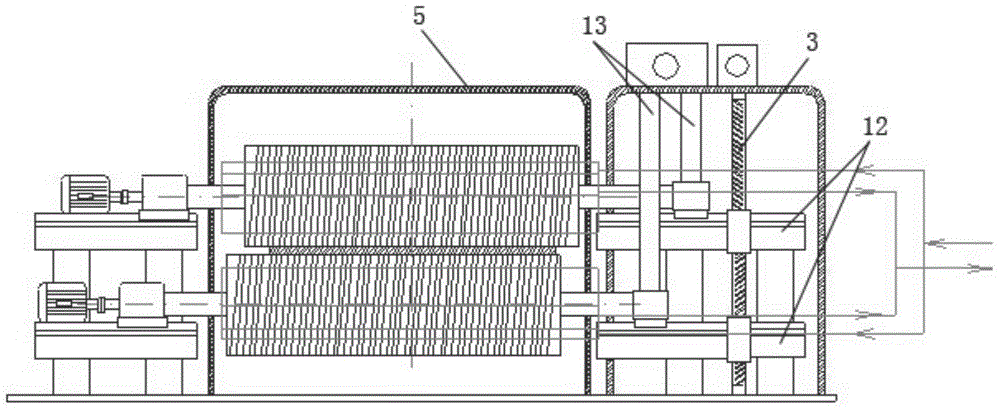

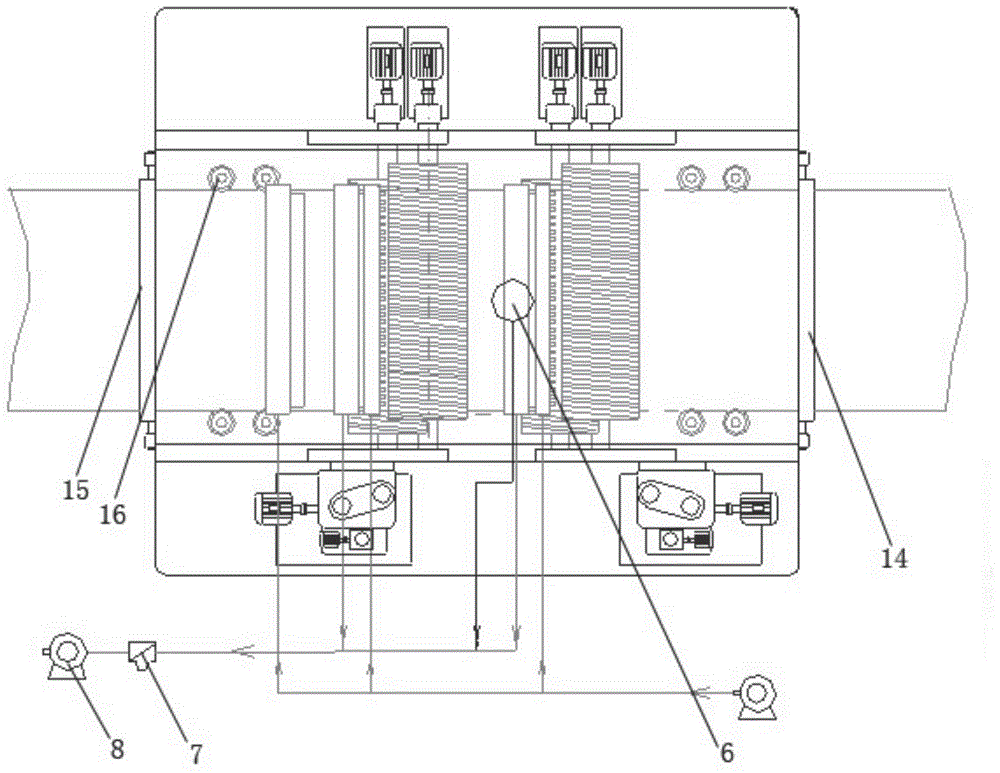

[0094] Such as figure 1 As shown, this figure only takes 2 pairs of brush rollers as an example, but the present invention is not limited to figure 1 2 pairs of brush rollers shown.

[0095] At the beginning of descaling, according to the thickness of the strip, the motor drives the brush roller to move up and down the gearbox, and the pair of brush rollers are opened up and down the roll gap through the movable screw; the strip is conveyed to the Exit pinch rollers to keep the strip tensioned within the unit. Start the high-speed nozzle and start the discharge fan. The roller gap between the brush roller pair is adjusted by the brush roller moving up and down by the motor, so that the flexible abrasive belt brush strip of the brush roller is in contact with the surface of the strip.

[0096] The drive motors of the brush rollers are respectively started to remove the oxide scale on the surface of the strip. The removed oxide scale is sent to the dust removal pipeline throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com