Preparation method of mineral source fulvic acid urea

A technology of fulvic acid and fulvic acid, which is applied in the direction of urea compound fertilizer, fertilizer mixture, organic fertilizer, etc., to achieve the effect of high quality and high performance, good slow release effect and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

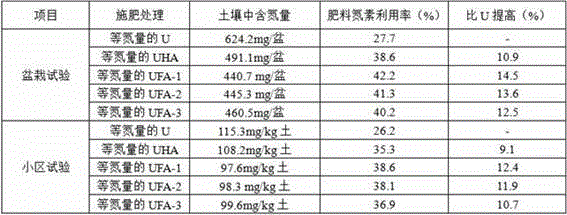

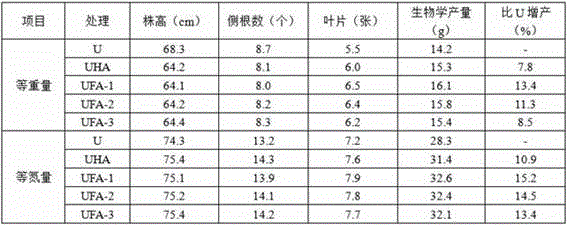

Examples

Embodiment 1

[0023] Mineral source fulvic acid urea described in the present embodiment is prepared according to the following steps:

[0024] (1) Dry the young coal to a moisture content of 20%, crush it and pass it through an 80-mesh sieve to obtain young coal powder for later use;

[0025] (2) Pulverize the rice flour and pass through an 80-mesh sieve to obtain rice flour, which is set aside;

[0026] (3) Mix the rice wheat stone powder and the young coal powder according to the weight ratio of 1:2000 to obtain the mixed powder and set aside;

[0027] (4) Pre-mix the three according to the mass ratio of potassium hydroxide solution: peracetic acid solution: hydrogen peroxide solution = 1: 5: 100 to obtain an oxidizing solution for later use, wherein the mass fraction of potassium hydroxide solution is 20 %, the mass percent concentration of peracetic acid in the peracetic acid solution is 20%, and the mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is ...

Embodiment 2

[0035] Mineral source fulvic acid urea described in the present embodiment is prepared according to the following steps:

[0036] (1) Dry the young coal to a moisture content of 18%, crush it and pass it through a 90-mesh sieve to obtain young coal powder for later use;

[0037] (2) Pulverize the rice flour and pass through a 90-mesh sieve to obtain rice flour and set aside;

[0038](3) Mix the rice wheat stone powder and the young coal powder according to the weight ratio of 1:1000 to obtain the mixed powder for later use;

[0039] (4) Pre-mix the three according to the mass ratio of potassium hydroxide solution: peracetic acid solution: hydrogen peroxide solution = 1:3:80 to obtain an oxidizing solution for later use, wherein the mass fraction of potassium hydroxide solution is 10 %, the mass percent concentration of peracetic acid in the peracetic acid solution is 15%, and the mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is 25%;

[004...

Embodiment 3

[0047] Mineral source fulvic acid urea described in the present embodiment is prepared according to the following steps:

[0048] (1) Dry the young coal to a moisture content of 15%, crush it and pass it through a 100-mesh sieve to obtain young coal powder for later use;

[0049] (2) Pulverize the rice flour and pass through a 100-mesh sieve to obtain rice flour and set aside;

[0050] (3) Mix the rice wheat stone powder and the young coal powder according to the weight ratio of 1:500 to obtain the mixed powder and set aside;

[0051] (4) According to the mass ratio of potassium hydroxide solution: peracetic acid solution: hydrogen peroxide solution = 1:1:50, the three are pre-mixed to obtain the oxidized solution, and the potassium hydroxide solution is 5% by mass. %, the mass percent concentration of peracetic acid in the peracetic acid solution is 10%, and the mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is 35%;

[0052] (5) According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com