A kind of method for preparing isobutene

A technology of isobutene and methyl bromide, which is applied in the field of isobutene production, can solve the problems of low selectivity of a single product, high selectivity of methyl bromide to synthesize isobutene, etc., and achieve simple and easy activation method, high conversion rate of methyl bromide and selectivity of isobutene, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

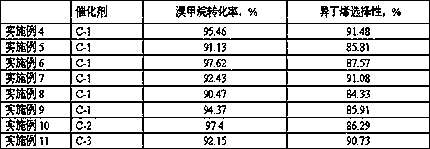

Examples

Embodiment 1

[0027] Weigh an appropriate amount of zinc nitrate and dissolve it in deionized water, and load it on alumina (the pore volume is 0.71ml / g, the specific surface area is 236m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, dried at 120°C for 4h, and calcined at 500°C for 8h to obtain the catalyst precursor ZnO / Al 2 o 3 . Put 5g of the catalyst precursor in a continuous flow fixed-bed reactor, and use a mixed gas of methyl bromide and nitrogen to treat the catalyst precursor. The volume concentration of methyl bromide is 80%, and the treatment conditions are 250°C, 0.3MPa (absolute pressure), 300h -1 , time 2h, prepared isobutene catalyst halide, denoted as C-1. Get catalyst weight composition as ZnBr 2 The weight content based on bromide is 30%, the weight content of ZnO based on oxide is 4%, the total acid content in the catalyst below 450°C is 0.93mmol / g, and the acid content between 250°C and 350°C accounts for the total acid content below 450°C 63.2% of the total...

Embodiment 2

[0029] Weigh an appropriate amount of zinc nitrate and dissolve it in deionized water, and load it on alumina (the pore volume is 0.71ml / g, the specific surface area is 236m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, dried at 80°C for 8h, and calcined at 600°C for 4h to obtain the catalyst precursor ZnO / Al 2 o 3 . Put 5g of the catalyst precursor in a continuous flow fixed-bed reactor, and use bromomethane to treat the catalyst precursor at 250°C, 0.2MPa (absolute pressure), 100h -1 , Time 2h, prepared isobutylene halide catalyst, denoted as C-2. Catalyst weight composition is ZnBr 2 The weight content is 39%, the ZnO weight content is 6%, the total acid content in the catalyst below 450°C is 0.98mmol / g, and the acid content at 250°C-350°C accounts for 64.5% of the total acid content below 450°C.

Embodiment 3

[0031] Weigh an appropriate amount of zinc nitrate and dissolve it in deionized water, and load it on alumina (the pore volume is 0.71ml / g, the specific surface area is 236m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, vacuum dried at 100°C for 8h, and calcined at 400°C for 8h to prepare the catalyst precursor ZnO / Al 2 o 3 . Put 5g of the catalyst precursor in a continuous flow fixed-bed reactor, and use a mixed gas of bromomethane and nitrogen to treat the catalyst precursor. The volume concentration of bromomethane is 30%, and the treatment conditions are 300°C, 0.1MPa (absolute pressure), 500h -1 , Time 4h, prepared isobutylene halide catalyst, denoted as C-3. Get catalyst weight composition as ZnBr 2 The weight content based on bromide is 18%, the weight content of ZnO based on oxide is 2%, the total acid content in the catalyst below 450°C is 0.72mmol / g, and the acid content between 250°C and 350°C accounts for the total acid content below 450°C 66.1% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com