Preparation method of calcium glycinate chelate

A technology of calcium glycinate and chelate compound, applied in the field of preparation of calcium glycinate chelate compound, can solve the problems of easily causing stones in the body and gastrointestinal irritation symptoms, restricting the development of industrialization, difficult crystallization of products, etc. The effect of not easy to agglomerate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

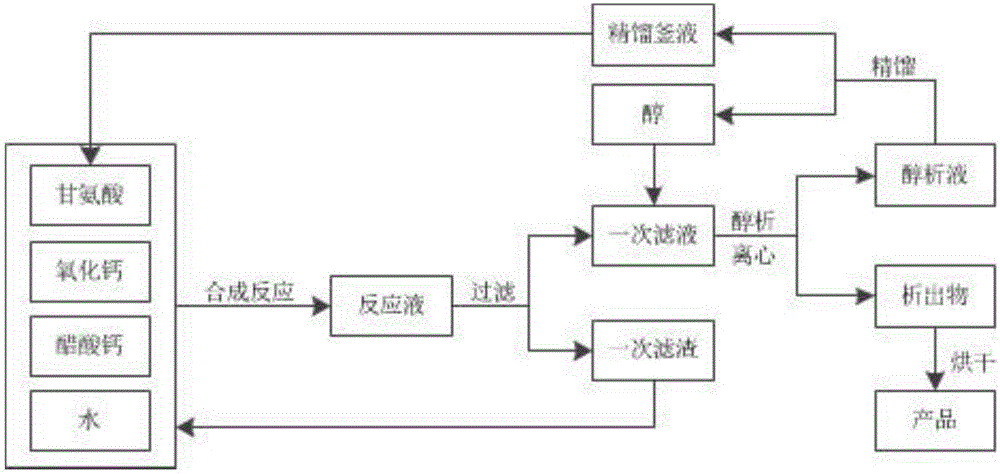

Method used

Image

Examples

Embodiment 1

[0034] Present embodiment is to prepare calcium glycinate chelate, concrete steps are as follows:

[0035] 1) Synthetic reaction: take raw materials glycine 75Kg (about 1 kilomole), calcium oxide 30.8Kg (about 0.55 kilomole), calcium acetate 3.95Kg (about 0.025 kilomole) and water 120 liters, put the raw materials into the reaction kettle, Stir and mix, heat to 75°C, and react for 4 hours to obtain a reaction solution;

[0036] 2) Product purification: filter the reaction solution while it is hot (at a temperature of 75° C.) to obtain a primary filtrate and a primary filter residue, then add 300 liters of ethanol to the primary filtrate for alcohol analysis. Separation, alcohol separation and precipitate were obtained, and the precipitate was dried at 50° C. for 4 hours to obtain 93.7 kg of calcium glycinate chelate product with a yield of 91%. After testing, the product purity was 99.82%.

[0037] 3) Post-treatment: The alcohol separation liquid was rectified at 80°C for 2 h...

Embodiment 2

[0042] Present embodiment is to prepare calcium glycinate chelate, concrete steps are as follows:

[0043] 1) Synthetic reaction: Take 150Kg (about 2 kilomoles) of raw material glycine, 61.6Kg (about 1.1 kilomoles) of calcium oxide, 7.9Kg (about 0.05 kilomoles) of calcium acetate and 240 liters of water, put the raw materials into the reaction kettle, Stir and mix, heat to 70°C, and react for 4 hours to obtain a reaction solution;

[0044] 2) Product purification: filter the reaction solution while it is hot (at a temperature of 70° C.) to obtain a primary filtrate and a primary filter residue, and then add 600 liters of ethanol to the primary filtrate for alcohol analysis. Separation, alcohol separation and precipitate were obtained, and the precipitate was dried at 50° C. for 4 hours to obtain 185.4 kg of calcium glycinate chelate product with a yield of 92%. After testing, the product purity was 100.50%.

[0045] 3) Post-processing: the alcohol separation liquid was rectif...

Embodiment 3

[0047]1) Synthetic reaction: take 75Kg (about 1 kilomol) of raw material glycine, 30.8Kg (about 0.55 kilomol) of calcium oxide, 3.16Kg (about 0.02 kilomol) of calcium acetate and 120 liters of water, and put the raw materials into the reaction kettle. Stir and mix, heat to 90°C, and react for 4 hours to obtain a reaction solution;

[0048] 2) Product purification: filter the reaction solution while it is hot (at a temperature of 80° C.) to obtain a primary filtrate and a primary filter residue, then add 400 liters of ethanol to the primary filtrate for alcohol analysis, and leave it to stand for 3 hours. Separation, alcohol separation liquid and precipitates were obtained, and the precipitates were dried at 40° C. for 6 hours to obtain 92.7 kg of calcium glycinate chelate product with a yield of 90%. After testing, the product purity was 99.95%.

[0049] 3) Post-processing: the alcohol separation liquid was rectified at 80°C for 2.5 hours to obtain 392 liters of ethanol, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com