Cationic polymerization method

A cationic polymerization and proton technology, applied in the field of cationic polymerization, can solve problems such as unsatisfactory, difficult preparation of initiator system, high technical requirements for the preparation of aluminoxane, etc., to reduce energy consumption, improve initiation efficiency, high polymer production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

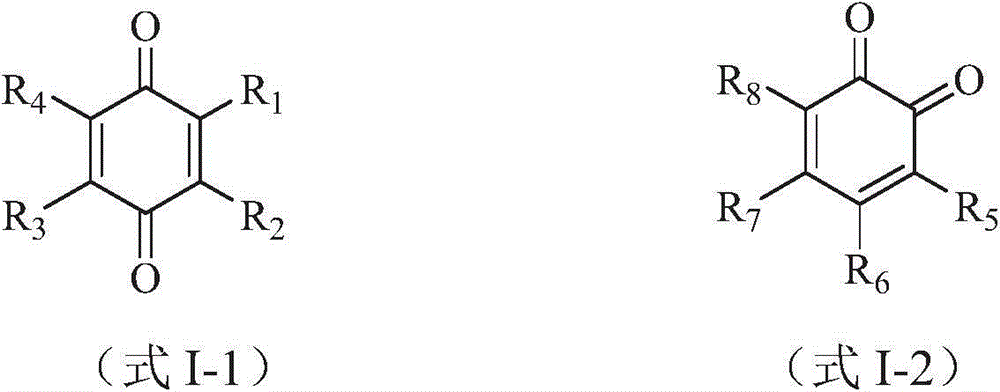

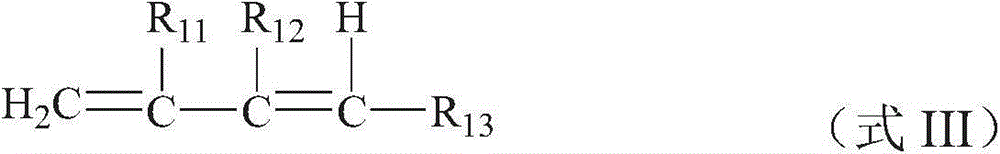

Method used

Image

Examples

Embodiment 1

[0082] (1) Dissolve 0.133 g of tetrachloro-p-benzoquinone in 66.5 g of dichloromethane solution to obtain a tetrachloro-p-benzoquinone solution. By weight, the concentration of tetrachloro-p-benzoquinone in the solution is 2000 ppm.

[0083] At -80℃, add 20mL of dichloromethane solution containing HCl (concentration of 0.0044mol / L) and 1.5mL of ethyl aluminum dichloride (concentration of 0.9mol / L) pre-cooled to -80℃ into 60mL shofar. L) The n-hexane solution and 1 mL of the aforementioned tetrachloro-p-benzoquinone solution are mixed uniformly and aged at -80° C. for 15 minutes to obtain an initiator solution. By weight, the concentration of tetrachloro-p-benzoquinone in the initiator solution is 100 ppm.

[0084] (2) In a 500mL glass reactor equipped with strong constant speed stirring, add 100mL of monochloromethane precooled to -60℃, 80mL of n-hexane precooled to -60℃, and 32mL of isobutylene precooled to -60℃. And 1mL of isoprene pre-cooled to -20°C and mix well. The initiat...

Embodiment 2

[0089] The polymerization was carried out using the same method as in Example 1, except that in the initiator solution obtained in step (1), the concentration of tetrachloro-p-benzoquinone was 400 ppm by weight; in step (2), the concentration of the initiator solution The addition amount is 20 mL, the temperature in the reactor is maintained in the range of -60°C to -65°C during the dropping process of the initiator solution and the polymerization reaction, and the polymerization reaction time is 15 minutes.

[0090] The polymer yield and the degree of unsaturation, molecular weight and molecular weight distribution index of the obtained polymer are listed in Table 1.

Embodiment 3

[0092] The polymerization was carried out using the same method as in Example 1, except that in step (1), the aging time was 30 minutes, and the obtained initiator solution had a concentration of 800 ppm by weight of tetrachloro-p-benzoquinone; step ( In 2), the addition amount of the initiator solution is 10 mL, the temperature in the reactor is maintained in the range of -85°C to -90°C during the dropping process of the initiator solution and the polymerization reaction, and the polymerization reaction time is 15 minutes.

[0093] The polymer yield and the degree of unsaturation, molecular weight and molecular weight distribution index of the obtained polymer are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com