Grafted copolymer of cellulose and derivatives thereof and synthesizing method of grafted copolymer

A technology of graft copolymer and synthesis method, which is applied in the field of polymer polymerization, can solve the problems that the graft copolymer of aromatic polyester is not suitable, the graft copolymer is not suitable for blending cellulose and PET, etc., and achieves good guidance. and application value, improve the compatibility of the two, and improve the effect of the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]First, dissolve 0.0348g ethylene glycol antimony in 10ml ethylene glycol (EG), add 66.4g terephthalic acid (TPA) into a 250ml four-necked flask, and add 34.6ml ethylene glycol. The reaction was carried out at 230°C under normal pressure for about 11 h until the system became transparent and the esterification reaction was completed. Vacuumize to 5000Pa and increase the system temperature to 265°C, react for 50 minutes, stop the reaction, pour the produced product into water while it is hot, and obtain PET with a number average molecular weight of 2512.

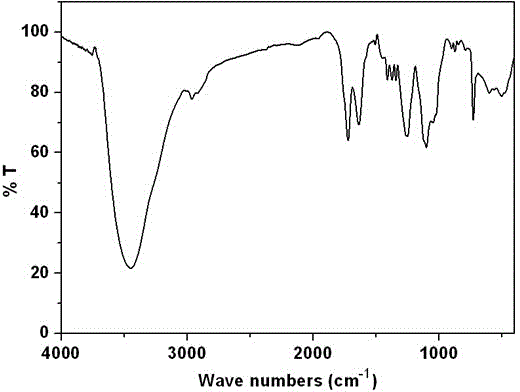

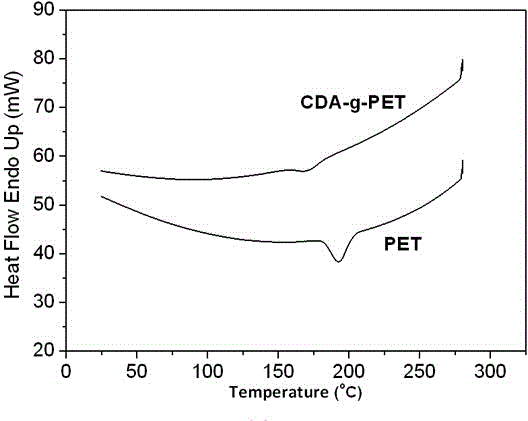

[0032] Take 1 gram of PET with a molecular weight of 2512 and dissolve it in 10ml of tetrachloroethane, add 0.045g of isophorone diisocyanate and 0.1ml of butyltin dilaurate, and react at 70°C for 6 hours to obtain an isocyanate-terminated prepolymer. 1 gram of nanocrystalline cellulose with a number average molecular weight of 50,000 was ultrasonically dissolved in 30 ml of acetone solution, added to the tetrachloroetha...

Embodiment 2

[0034] First, dissolve 0.038g ethylene glycol antimony in 10ml ethylene glycol (EG), add 66 g terephthalic acid (TPA) into a 250ml four-necked flask, and add 30ml ethylene glycol. React at 220°C under normal pressure for about 12 hours until the system becomes transparent and the esterification reaction is complete. Vacuumize to 4000Pa and increase the system temperature to 250°C for 30 minutes of reaction; evacuate to 300Pa and raise the system temperature to 285°C for 10 minutes of polycondensation. The reaction was stopped, and the produced product was poured into water while it was hot to quench to obtain PET with a number average molecular weight of 4316.

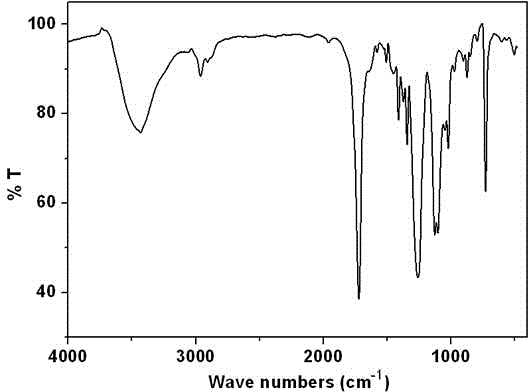

[0035] Dissolve 0.8g of PET with a molecular weight of 4316 in 10ml of tetrachloroethane, add 0.019g of 2,4-toluene diisocyanate and 0.08ml of dibutyltin diacetate, and react at 70°C for 4 hours to obtain a prepolymerized isocyanate things. 0.5 g of cellulose diacetate with a number average molecular weight of 70,000...

Embodiment 3

[0038] First, dissolve 0.042g of ethylene glycol antimony in 10ml of ethylene glycol (EG), add 66g of terephthalic acid (TPA) into a 250ml four-necked flask, and add 20ml of ethylene glycol. The reaction was carried out under normal pressure at 210°C for about 12 h until the system became transparent and the esterification reaction was completed. Vacuumize to 4000Pa and raise the system temperature to 250°C, and react for 30min. Vacuumize to 300 Pa, raise the temperature of the system to 285°C, and polycondense for 20 minutes. The reaction was stopped, and the produced product was poured into water while it was hot to quench to obtain PET with a number average molecular weight of 6036.

[0039] Dissolve 2g of PET with a molecular weight of 6036 in 10ml of tetrachloroethane, add 0.042g of 4,4'-diphenylmethane diisocyanate and 0.2ml of butyltin dilaurate, and react at 70°C for 5 hours to obtain terminal isocyanate prepolymer. 0.5 g of cellulose diacetate with a number average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com