Glass fiber-reinforced AES resin material and preparation method thereof

A technology of resin material and glass fiber, which is applied in the field of glass fiber reinforced AES resin material and its preparation, can solve the problems of low strength of AES resin, insufficient mechanical properties of AES, wide application of cost constraints, etc., and achieves easy implementation, wide application range, The effect of bending performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

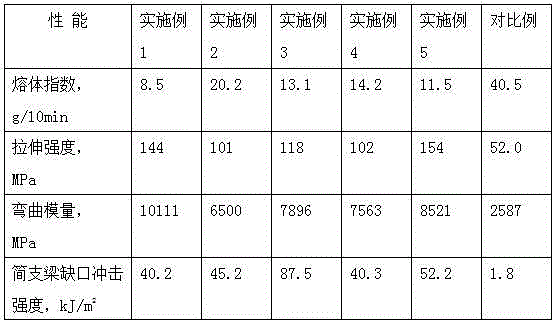

Embodiment 1~5 and comparative example 1

[0027] Each component and parts by weight in the following embodiments are shown in Table 1, and then the glass fiber reinforced AES resin material is prepared according to the following preparation method, and the preparation steps are:

[0028] 1. Weigh each component according to the proportioning in Table 1;

[0029] 2. Put AES, compatibilizer, coupling agent and tributyl citrate in a high mixer and mix for 2 to 10 minutes;

[0030] 3. Put the mixed raw materials in the twin-screw extruder, and then directly add the continuous non-alkali glass fiber through the feeding section of the extruder; then melt extrusion, drawing, water cooling, and pelletizing to obtain glass fiber Reinforced AES resin material; among them, the aspect ratio of the twin-screw extruder is 40:1; the temperature of the screw barrel is set as: the temperature of the first zone is 210°C, the temperature of the second zone is 215°C, the temperature of the third zone is 215°C, and the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com