Corrosion-resistant water-based ultrathin fireproof coating for steel structure

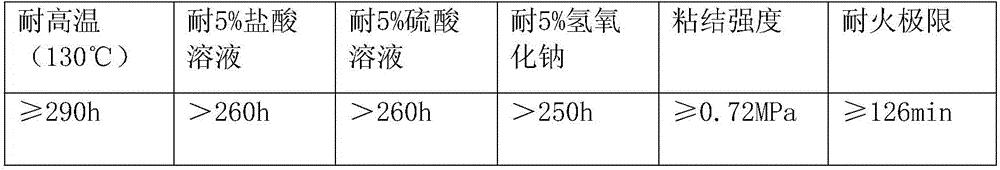

A fireproof coating, ultra-thin technology, applied in the field of coatings, can solve the problems of poor corrosion resistance and flame retardancy, single film-forming material, poor synergistic effect of flame retardants, etc., to achieve excellent corrosion resistance, weather resistance Good aging resistance and strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a nitrogen protection atmosphere, triethoxyborane and silicon tetrachloride are mixed and stirred in a weight ratio of 100:1, and the metallocene catalyst and the cocatalyst are slowly added while stirring for a stirring reaction for 5 hours; then Slowly add silicon tetrachloride and excess distilled water that account for 60% of the weight of triethoxyborane to the aforementioned reaction solution for hydrolysis reaction for 5 hours, then wash the reaction product and remove small molecules by distillation under reduced pressure to obtain a liquid Polyborosiloxane flame retardant;

[0028] (2) Mix 10 parts of polyborosiloxane flame retardant, 30 parts of intumescent flame retardant, 5 parts of isothiazolinone derivatives and additives (polyurea grafted hydroxyl acrylic resin, dispersant, rust inhibitor) Add 1 part to 15 parts of water for mixing, then pump into a grinder to grind to a fineness ≤ 80 μm; finally add 5 parts of styrene-acrylic emulsion and 10 parts...

Embodiment 2

[0032] (1) In a nitrogen protection atmosphere, triethoxyborane and silicon tetrachloride were mixed and stirred in a weight ratio of 100:8, and a metallocene catalyst and a cocatalyst were slowly added while stirring for a stirring reaction for 9 hours; then Slowly add silicon tetrachloride accounting for 140% by weight of triethoxyborane and excess distilled water to the aforementioned reaction solution for hydrolysis reaction for 6 hours, then wash the reaction product and remove small molecules by distillation under reduced pressure to obtain liquid Polyborosiloxane flame retardant;

[0033] (2) 15 parts of polyborosiloxane flame retardant, 55 parts of intumescent flame retardant, 3 parts of 1,2-benzisothiazolin-3-one and auxiliary agent (polyurea grafted hydroxyl acrylic resin, Dispersant, antirust agent) 3 parts are added to 30 parts of water for mixing, then pumped into the grinder and ground to a fineness ≤ 80 μm; finally, 10 parts of styrene-acrylic emulsion and 25 pa...

Embodiment 3

[0035] (1) In a nitrogen protection atmosphere, triethoxyborane and silicon tetrachloride were mixed and stirred in a weight ratio of 100:5, and a metallocene catalyst and a cocatalyst were slowly added to carry out a stirring reaction for 7 hours while stirring; Slowly add silicon tetrachloride and excess distilled water that account for 100% of the weight of triethoxyborane to the aforementioned reaction solution for hydrolysis for 5 hours, then wash the reaction product and remove small molecules by distillation under reduced pressure to obtain a liquid Polyborosiloxane flame retardant;

[0036] (2) 12 parts of polyborosiloxane flame retardant, 40 parts of intumescent flame retardant, 4 parts of isothiazolinone derivatives and auxiliary agents (polyurea grafted hydroxyl acrylic resin, dispersant, rust inhibitor) Add 2 parts to 20 parts of water for mixing, then pump into a grinder to grind to a fineness ≤ 80 μm; finally add 8 parts of styrene-acrylic emulsion and 15 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com