Patents

Literature

33results about How to "Improve weather resistance and aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensitive adhesive for protective film and preparation method thereof

InactiveCN101798491AHigh initial tackImprove cohesive strengthEster polymer adhesivesTectorial membraneFunctional monomer

The invention discloses a pressure sensitive adhesive for a protective film and a preparation method thereof. The pressure sensitive adhesive is formed by polymerizing acrylic monomers through radicals, wherein the acrylic monomers comprise the following components in percent by weight: 30-50 percent of acrylic soft monomer, 5-20 percent of acrylic hard monomer, 0.5-2.5 percent of acrylic functional monomer, 0.5-2.5 percent of acrylic crosslinking monomer, 40-60 percent of solvent, 0.2-2.0 percent of initiating agent and 0.01-0.2 percent of chain transfer agent. The adhesive has higher initial adhesion and permanent adhesion and excellent weather-proof and aging-resisting performances and can meet the requirement of a protective film adhesive with higher strength requirement.

Owner:BEIJING COMENS NEW MATERIALS

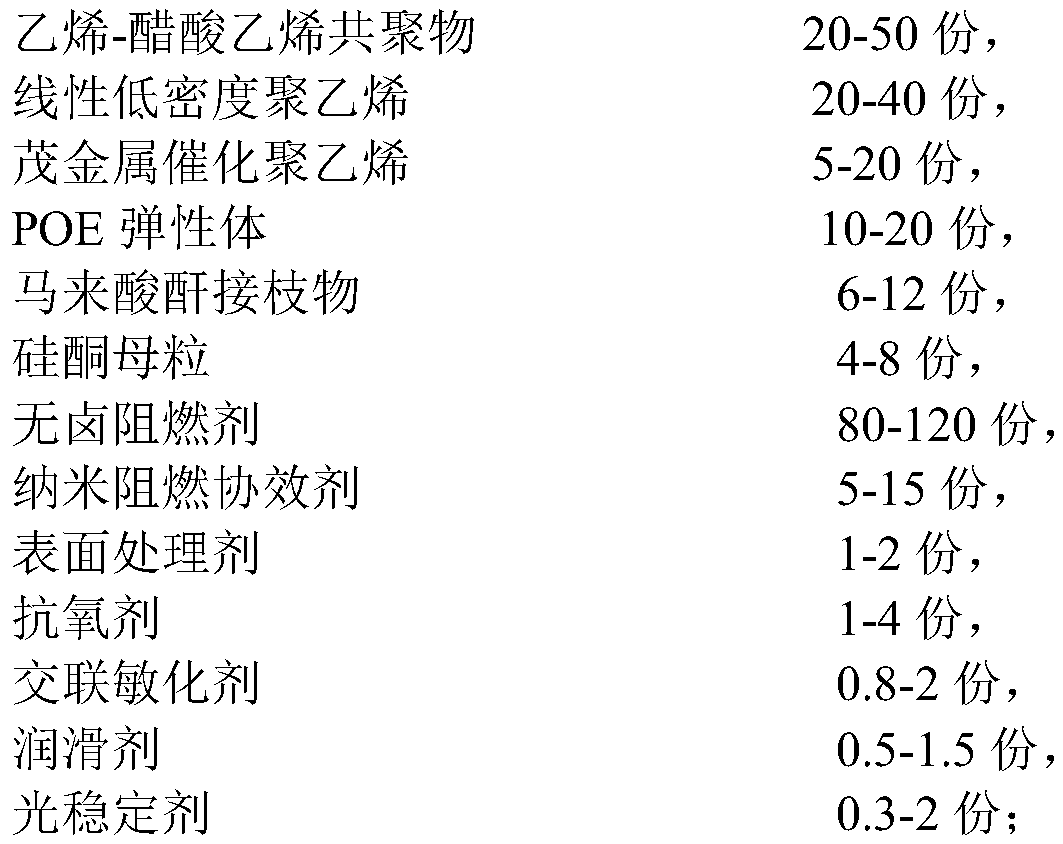

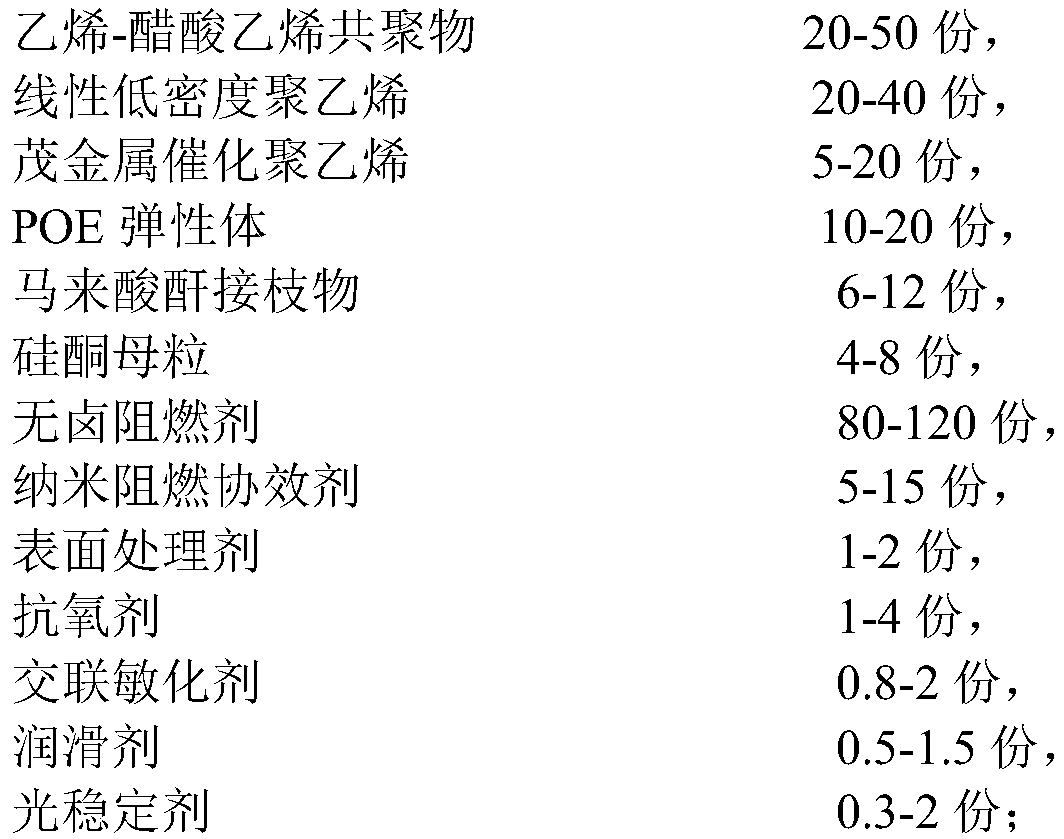

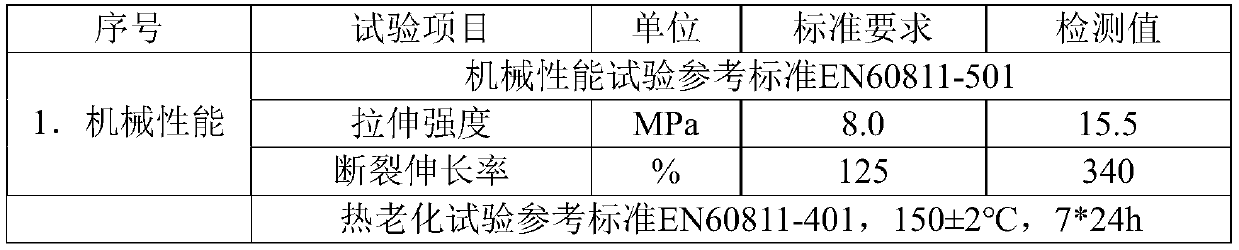

125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for photovoltaic cable and preparation method thereof

PendingCN111234358AGood mechanical propertiesEasy to operatePlastic/resin/waxes insulatorsMaleic anhydrideWeather resistance

The invention discloses a 125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for a photovoltaic cable and a preparation method of the cable material. The cable material is prepared from, by mass 20 to 50 parts of an ethylene-vinyl acetate copolymer, 20 to 40 parts of linear low density polyethylene, 5 to 20 parts of metallocene catalyzed polyethylene, 10-20 parts of a POE elastomer, 6-12 parts of maleic anhydride graft, 4-8 parts of silicone masterbatch, 80-120 parts of a halogen-free flame retardant, 5-15 parts of a nano flame retardant synergist, 1-2 parts of a surface treating agent, 1-4 parts of an antioxidant, 0.8-2 parts of a cross-linking sensitizer, 0.5-1.5 parts of a lubricant and 0.3-2 parts of a light stabilizer. The cable material hasgood mechanical property, electrical insulation property, flame retardant property, weather resistance, aging resistance, scratch resistance, acid and alkali resistance and processability, and a photovoltaic cable prepared from the cable material can meet the requirements of German 2Pfg1169 and European EN50618 standards after being subjected to irradiation processing; the preparation method hasthe advantages of simple operation, high production efficiency and high process automation, and is beneficial to plasticization and dispersion of each raw material component.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

Watersoluble pure acrylic emulsion for construction and method of producing the same

InactiveCN101368053AModerate viscosityImprove stabilityEmulsion paintsSodium bicarbonatePotassium persulfate

The invention discloses aqueous building pure acrylic emulsion and a preparation method thereof, which belongs to the technical field of paint and is improved based on the prior art. The emulsion is synthesized with the materials by the following weight percent: 65 to 75 percent of de-ionized water; 10 to 15 percent of methyl methacrylate; 10 to 20 percent of butyl acrylate; 1 to 5 percent of methacrylic acid; 0.4 to 1 percent of OP-10; 0.1 to 0.5 percent of sodium dodecyl benzene sulfonate; 0.1 to 0.6 percent of potassium persulfate; 0.1 to 0.5 percent of sodium bicarbonate; 0.1 to 0.5 percent of reactive emulsifying agent; and 0.1 to 0.2 percent of ammonia. The aqueous building pure acrylic emulsion has the advantages of acid resistance, alkali resistance, excellent imperviousness, excellent low temperature flexibility, weatherability and ageing resistance, proper viscosity of pure acrylic emulsion, high stability, simple synthetic process, low price, no environmental pollution and meeting the technical requirement of aqueous building pure acrylic emulsion, thus being very promising in application in market.

Owner:JIANGSU UNIV OF SCI & TECH

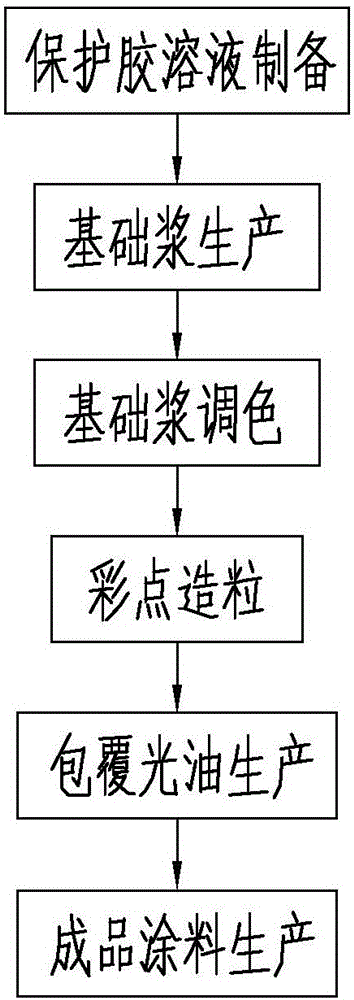

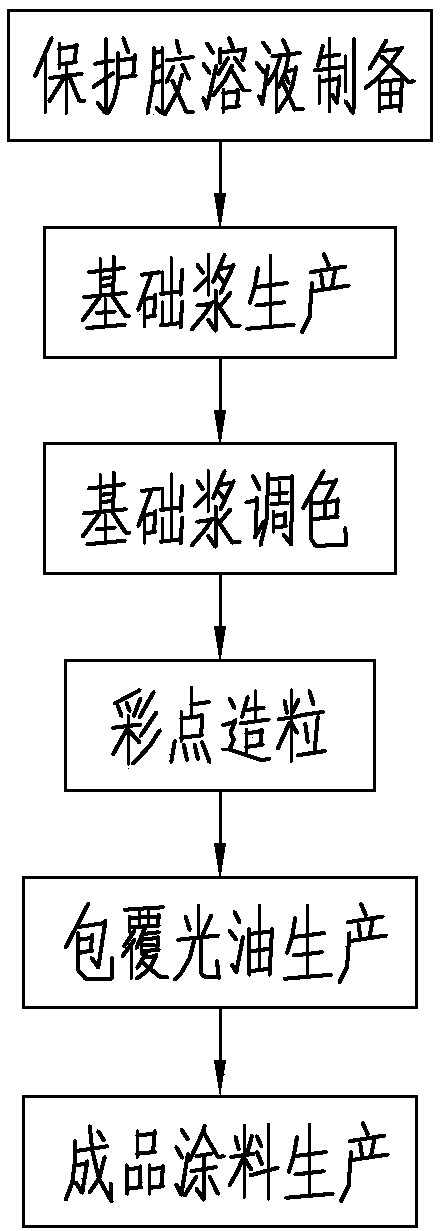

Production method of water-in-water colorful paint containing color sand

ActiveCN105925096ACost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

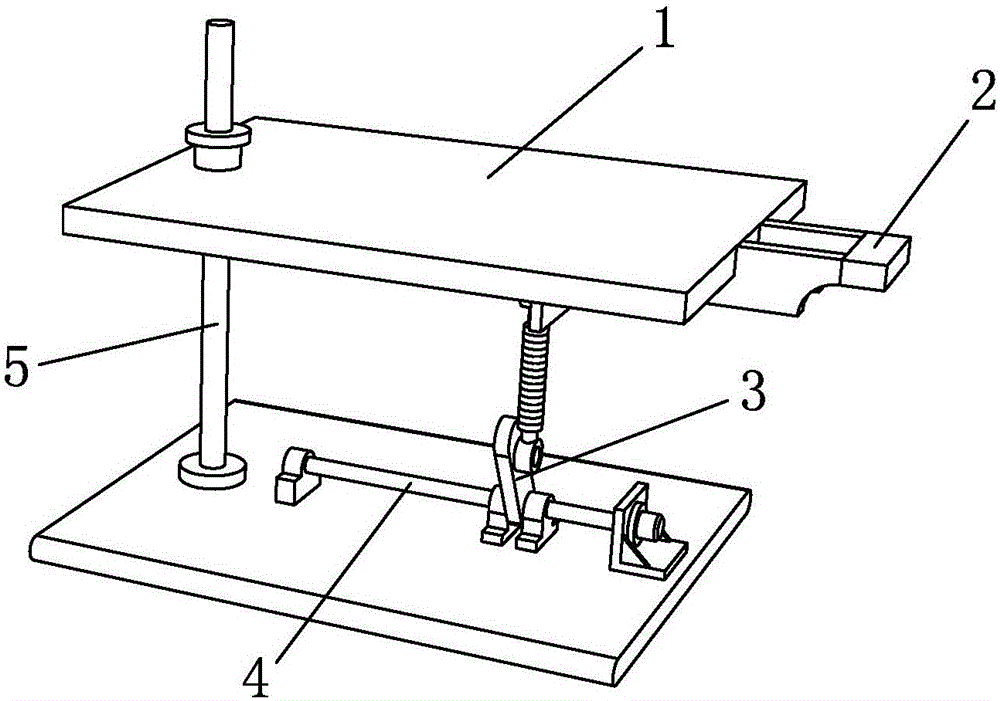

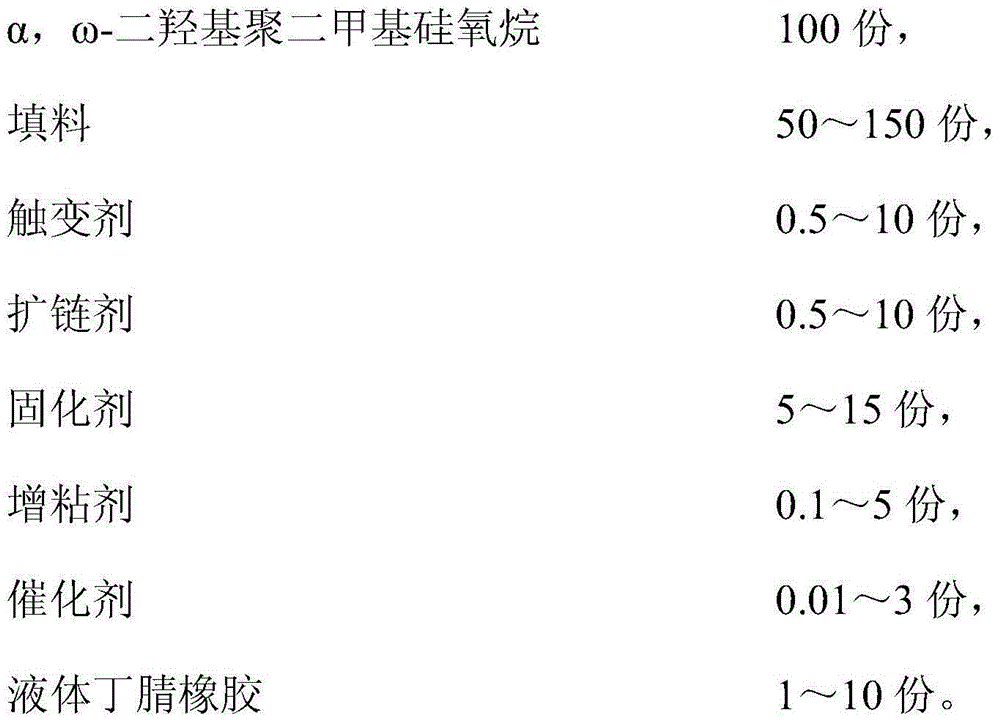

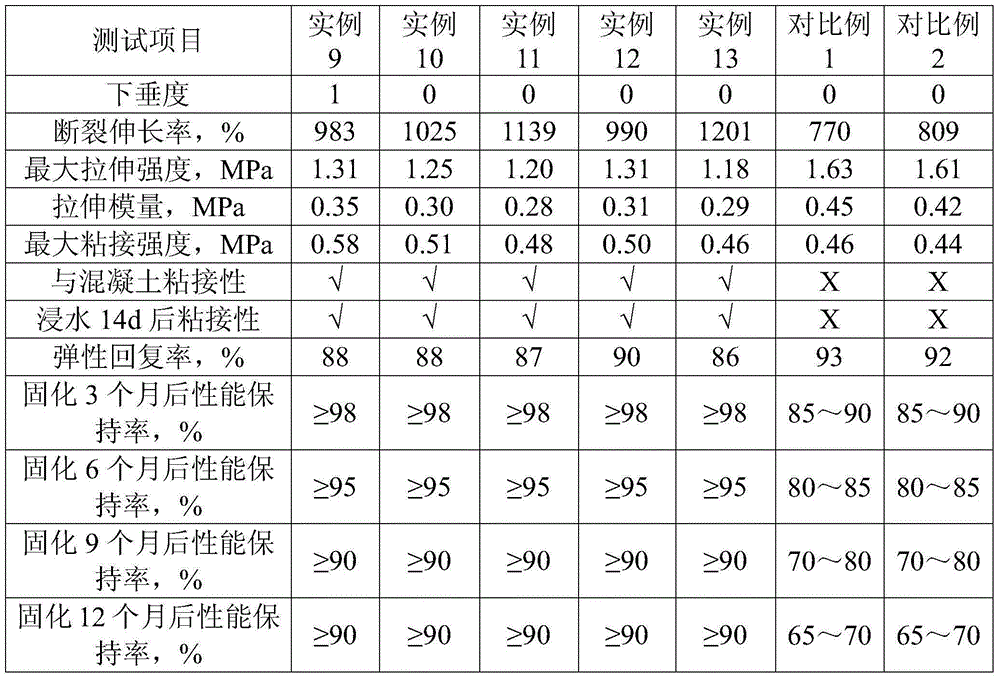

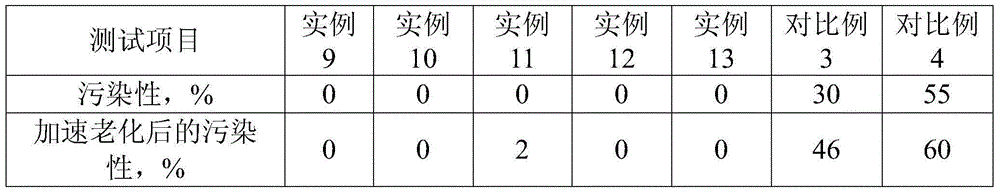

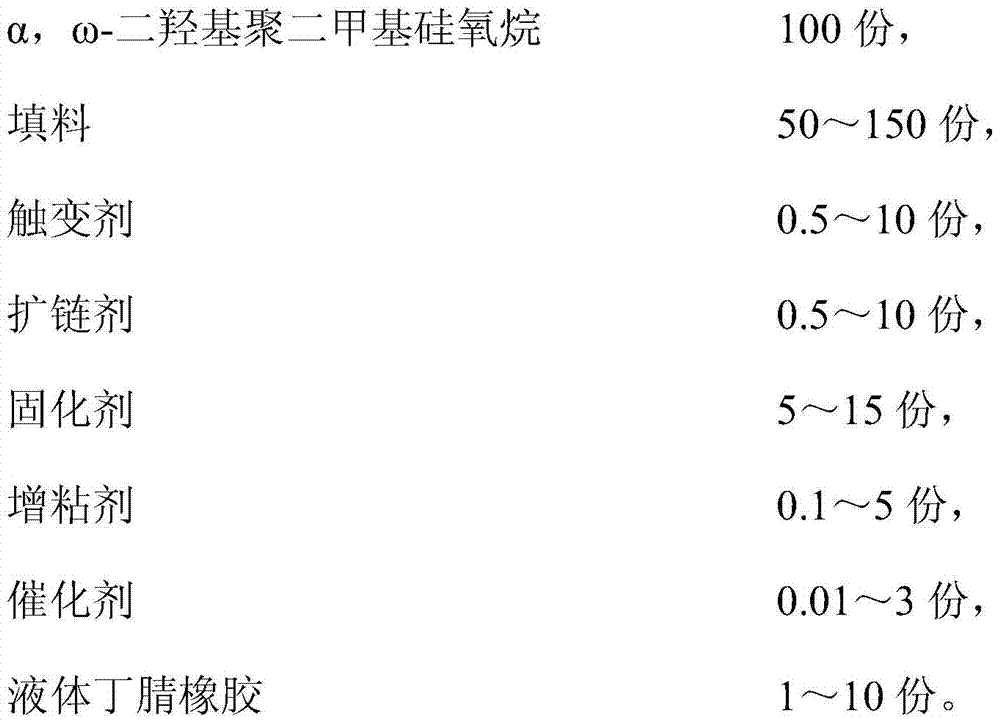

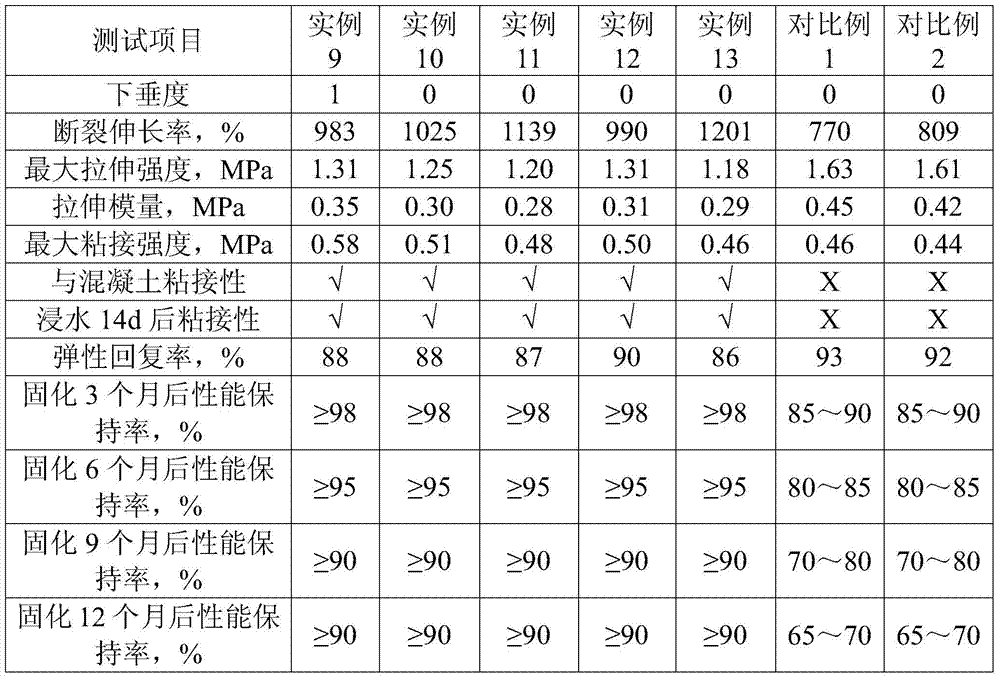

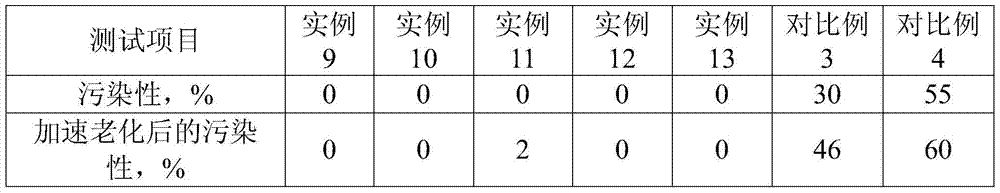

High-stability concrete silicone joint glue and preparing method thereof

ActiveCN105131899AImprove performanceImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesOmegaAdhesion strength

The invention discloses high-stability concrete silicone joint glue and a preparing method thereof. The joint glue is prepared, by mass, 100 parts of alpha,omega-dihydroxyl polydimethylsiloxane, 50-150 parts of packing, 0.5-10 parts of thixotropic agent, 0.5-10 parts of chain extender, 5-15 parts of curing agent, 0.1-5 parts of thickening agent, 0.01-3 parts of catalyst and 1-10 parts of liquid chemigum. The alpha,omega-dihydroxyl polydimethylsiloxane, the thixotropic agent and the packing are made into a base material in a kneading machine, then the base material is transferred into a high-speed dispersing machine, residual raw materials are added, a reaction is conducted, and the joint glue is obtained. According to the high-stability concrete silicone joint glue and the preparing method thereof, the silicone joint glue is modified through the liquid chemigum, the specific chain extender is adopted, permanent toughness and the mechanical property retention rate are given to the joint glue, a plasticizer is not transferred, adhesion is not damaged, meanwhile, the adhesion strength is greatly improved, the ageing resistance is good, environmental friendliness is achieved, and pollution does not exist.

Owner:CHENGDU GUIBAO SCI & TECH

Mold and coating used for mold

PendingCN109988502AStir wellHigh coating strengthFireproof paintsAnti-corrosive paintsWater basedSolvent

The application provides a mold and a coating used for the mold, and belongs to the technical field of coating compositions. The coating comprises the following components, in percentages by mass: 25-35% of bonding resin, 5-15% of a filler, 2-10% of an auxiliary agent and 35-50% of a solvent, wherein the bonding resin adopts a mixed water-based resin dispersion liquid; the filler is one or a mixture of more selected from the group consisting of chromium oxide green micro powder, silicon carbide micro powder, nano silicon dioxide powder and molybdenum disulfide micro powder; and the solvent iswater. When the coating provided by the invention is applied to the mold, especially fluorine-silicon modified tire mold processing, the demolding property is ensured, the adhesion between the coatingand the mold is improved, and the green environmentally-friendly pollution-free processing is realized.

Owner:ZHEJIANG LAIFU MOLD

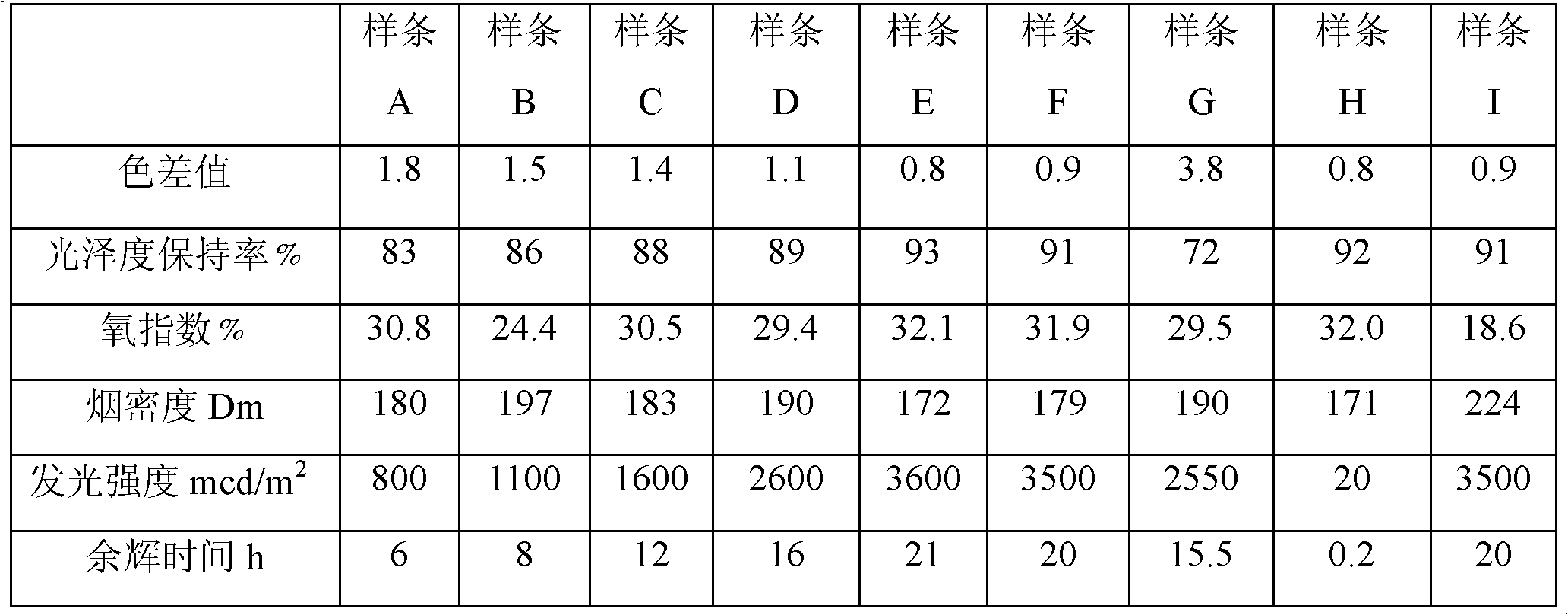

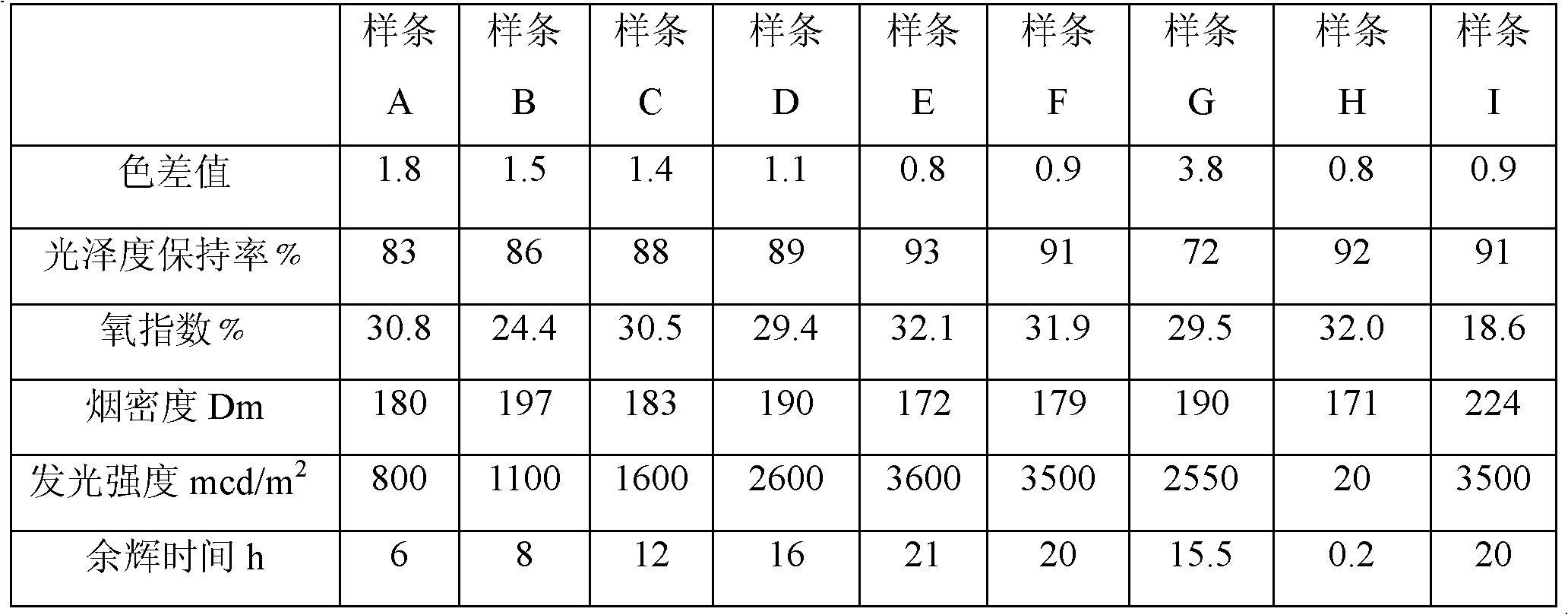

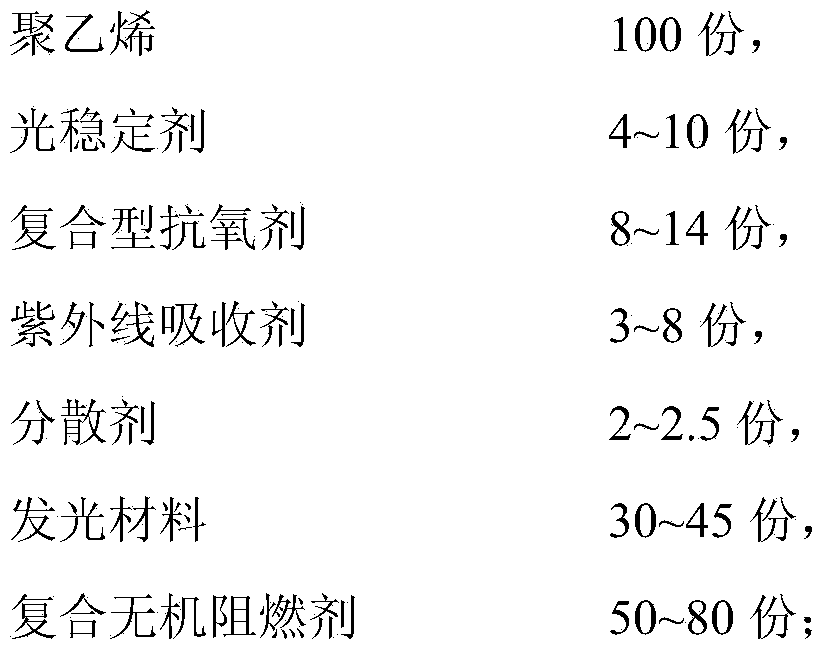

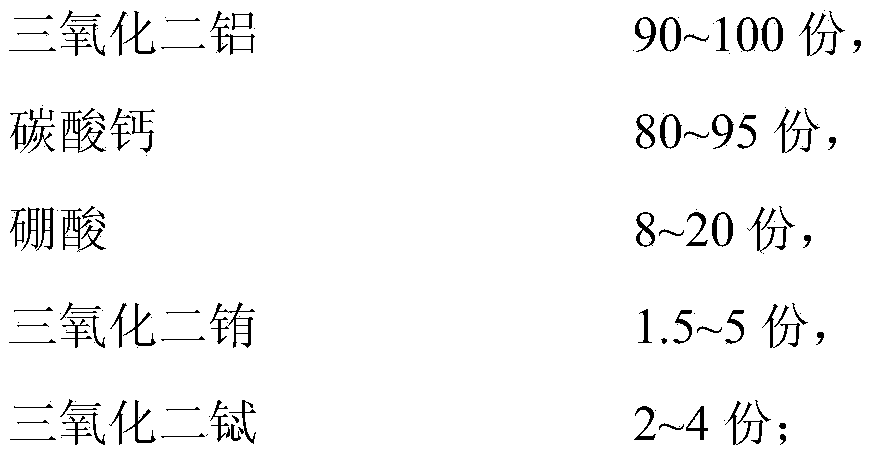

Luminescent material and preparation method and application thereof

ActiveCN102807866AGood weather resistanceStrong persistenceLuminescent compositionsMasterbatchWeather resistance

The invention belongs to the technical field of modifying and processing technology for macromolecule, and relates to a luminescent material and a preparation method and application thereof. The luminescent material includes the following components based on weight proportion: 90-100 portions of aluminium oxide, 80-95 portions of calcium carbonate, 8-20 portions of boric acid, 1.5-5 portions of europium oxide, 2-4 portions of terbium oxide. Compared with the prior art, master batches of weather-resistant energy-storage luminescent polyethylene plastic prepared from the luminescent material of the invention have excellent weather-resistant performance and durability, environment-friendly degradation products, longer luminescence time and zero radioactivity. The master batches of the luminescent material are widely used in architectural ornament, transportation, fire protection, electrocommunication, subway tunnels, advertising boards and other plastic products.

Owner:江苏融威实业有限公司

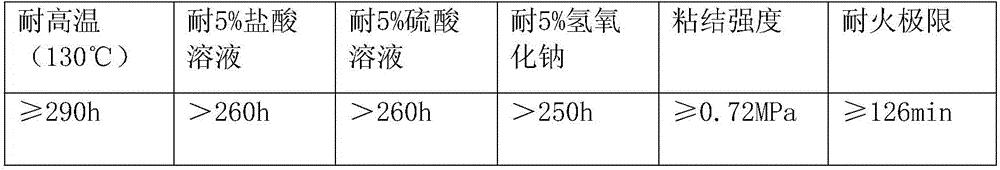

Corrosion-resistant water-based ultrathin fireproof coating for steel structure

InactiveCN106147603APerformance synergyImprove weather resistance and aging resistanceFireproof paintsWater basedWeather resistance

The invention discloses a corrosion-resistant water-based ultrathin fireproof coating for a steel structure and a preparation method thereof. The corrosion-resistant water-based ultrathin fireproof coating is prepared from, by weight parts, 5-10 parts of styrene-acrylic emulsion, 10-25 parts of acrylic acid emulsion, 10-15 parts of polyborosiloxane flame retardant, 30-55 parts of intumescent flame retardant, 3-5 parts of preservative, 1-3 parts of auxiliaries and 15-30 parts of water. The corrosion-resistant water-based ultrathin fireproof coating for the steel structure is good in weather resistance and aging resistance, excellent in corrosion resistance, high in force of adhesion to steel and good in caking property and has effects of long-acting fire prevention, long-term weather resistance and aging resistance.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

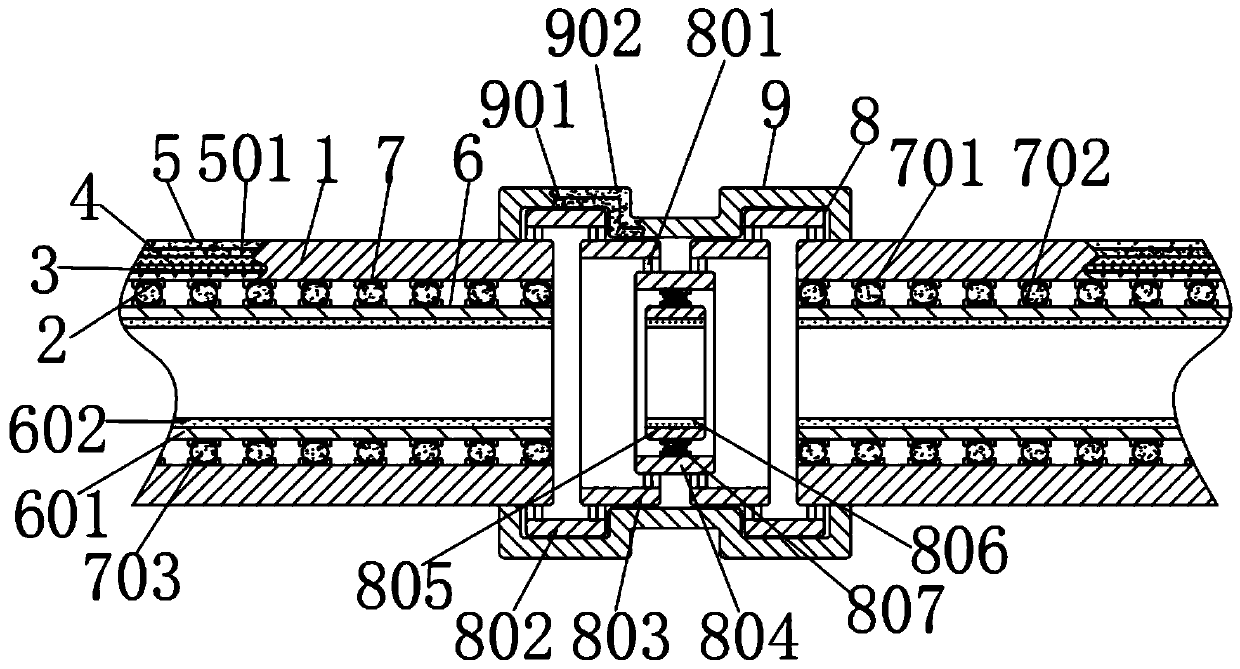

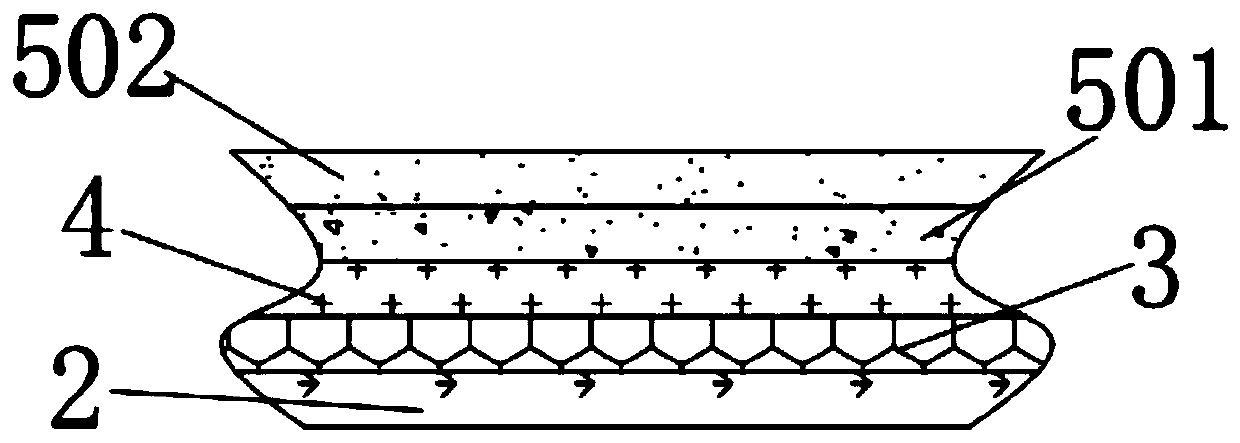

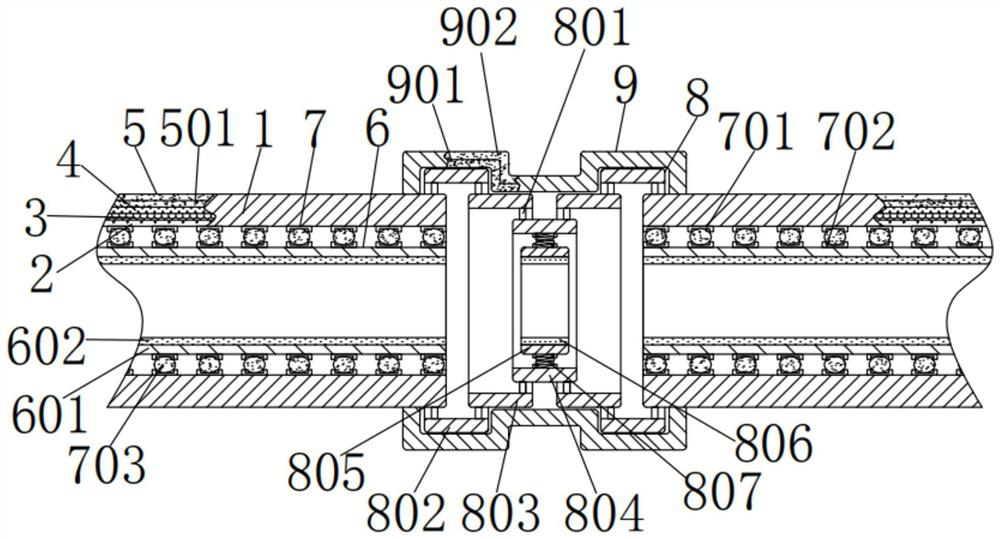

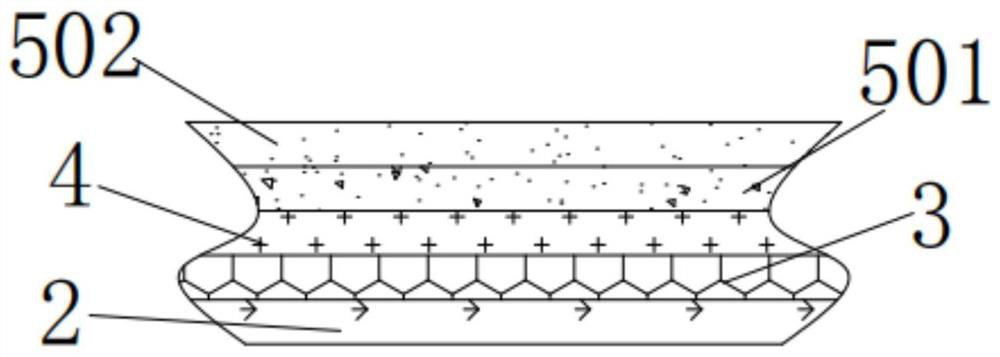

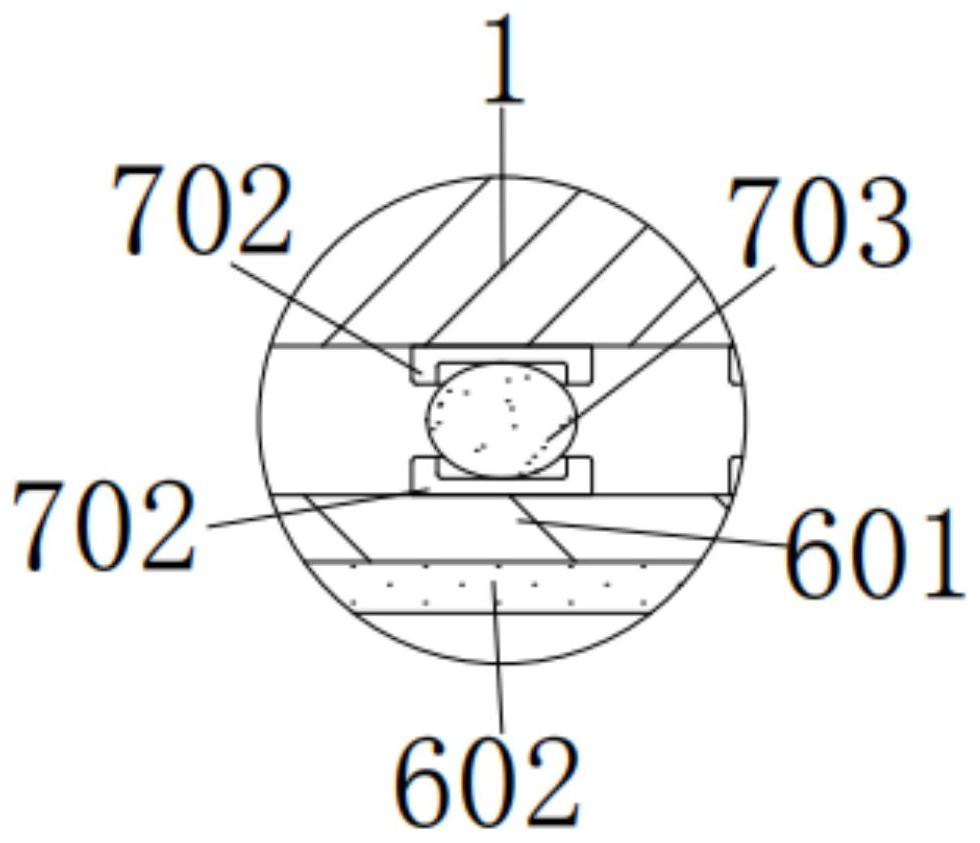

Glass fiber reinforced plastic optical cable protection sleeve

ActiveCN111180149AScientific and reasonable structureEasy to useCable installations in surface ductsPlastic/resin/waxes insulatorsEpoxyPolyester

The invention discloses a glass fiber reinforced plastic optical cable protection sleeve, which comprises a first glass fiber reinforced plastic pipe, wherein the first glass fiber reinforced plasticpipe is formed by compounding glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin; a first polytetrafluoroethylene waterproof material layer is coated on the outer wall of thefirst glass fiber reinforced plastic pipe; and a first silicide heat insulation cotton layer is glued on the outer wall of the first polytetrafluoroethylene waterproof material layer. According to the glass fiber reinforced plastic optical cable protection sleeve, the first polytetrafluoroethylene waterproof material layer is matched with the first silicide heat insulation cotton layer, so that the first glass fiber reinforced plastic pipe has stable temperature resistance based on temperature resistance performance of the first polytetrafluoroethylene waterproof material layer and the firstsilicide heat insulation cotton layer, and through the temperature resistance of a second polytetrafluoroethylene waterproof material layer and a second silicide heat insulation cotton layer, the optical cables in a first cylinder body, a second cylinder body and a third cylinder body can stably work.

Owner:五合兴华通讯设备有限公司

Water-in-water multicolor paint containing color sand

ActiveCN106085062AImprove stabilityHigh viscosityAntifouling/underwater paintsPaints with biocidesCellulosePowder mixture

The invention discloses water-in-water multicolor paint containing color sand. The water-in-water multicolor paint comprises color-sand-containing basic paint, a protective glue solution, cladding gloss oil and an addition agent; basic slurry is prepared from the following raw materials in parts by mass: 200-400 parts of water, 3-8 parts of cellulose ether, 7.5 parts of propylene glycol, 1 part of a moist dispersing agent, 1 part of a PH adjusting agent, 10 parts of a film-forming addition agent, 1 part of an antifoaming agent, 80-130 parts of a kaolin and heavy calcium powder mixture, 1-2 parts of barium metaborate, 200-400 parts of an acrylic emulsion, 1 part of bactericides, 1 part of a dispersing agent, 1 part of a stabilizing agent, 50 parts of 6.5% protective glue, 0.5-1 part of aqueous polishing paste, and 1-2 parts of sodium phosphate tripolymer. The water-in-water multicolor paint is level in surface and not liable to cause ash deposition, can maintain whole appearance for a long term, and has dirty resistance. The specially-made cladding gloss oil can maintain the color of the surface of the water-in-water multicolor paint containing color sand bright for a long time, and has weather resistance. The water-in-water multicolor paint has good water resistance and anti-corrosive properties, and protects the whole modeling of a building. Shaped patterns are plain, and elegant in appearance. Besides, the water-in-water multicolor paint has good stability and extremely high market economy value.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

Nanometer bi-layer film biogas digester material and preparation method thereof

ActiveCN102558713AOvercoming tensile strengthOvercome the disadvantage of large influence on elongation at breakAntioxidantRed mud

The invention discloses a nanometer bi-layer film biogas digester material, which is composed of the following components: PVC (polyvinyl chloride) resin, DOP (Dioctyl-Phthalate), DBP (dibutyl phthalate), a stabilizing agent, an antioxidant, an anti-UV (ultraviolet) agent, nano calcium carbonate, modified red mud and other accessory ingredients, wherein the components are subjected to the calendering technology, the fitting technology and the surface treatment technology, and two groups of single-surface surface-treated single-layer biogas digester materials are combined to obtain the bi-layer biogas digester material. The nanometer bi-layer film biogas digester material has the advantages that nano calcium carbonate and the modified red mud are adopted to serve as filling agents, thus the weather resistance, the aging resistance and the like of a PVC film are improved and the service life of the bi-layer film biogas digester material is prolonged; the acrylate coating is used for surface treatment, thus the weather resistance and the aging resistance of the bi-layer film biogas digester material are improved; and because of adopting the bi-layer film structure, the inner-layer film has excellent air impermeability and chemical corrosion resistance, and the outer-layer film has good physical and mechanical property and aging resistance so as to prevent the inner-layer film from being damaged by the external environment.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Ecological and environment-friendly high-performance garden pavement material and preparation method thereof

The invention discloses an ecological and environment-friendly high-performance garden pavement material. The ecological and environment-friendly high-performance garden pavement material is prepared from, by weight, 7-9 parts of asphalt, 10-14 parts of fibrous material, 2-4 parts of reinforcer, 3-5 parts of hardener, 6-8 parts of inorganic binder, 7-9 parts of coarse aggregate, 6-8 parts of white cement gum, 7-9 parts of fine aggregate and 6-10 parts of mineral powder. The ecological and environment-friendly high-performance garden pavement material has the advantages of being high in mechanical strength, capable of preventing cracking and good in water permeability, and is small in cement use amount, nonpoisonous and tasteless and good in weather resistance and ageing resistance; the adopted raw materials are environmentally friendly, low in cost and easy to obtain, the process is simple and clear, and the ecological and environment-friendly high-performance garden pavement material has high practical value and good application prospects.

Owner:HEFEI SHENWO HORTICULTURE CO LTD

Antimicrobial wood softener containing nanometer titanium dioxide and preparation method thereof

InactiveCN105984007AImprove breathabilityHigh strengthWood treatment detailsPressure impregnationFiberAging resistance

The invention discloses an antimicrobial wood softener containing nanometer titanium dioxide. According to the wood softener, traditional aqueous ammonia, sodium potassium tartrate tetrahydrate, quaternary ammonium salt of chitosan and the like are mixed to prepare a fundamental softening solution, and sericin powder and the nanometer titanium dioxide are added to the fundamental softening solution. Because nanometer particles permeate the wood, the strength of wood can be effectively improved, and the weather-proof performance and the ageing-resistance performance can be improved. Meanwhile, the nanometer titanium dioxide has a certain antimicrobial property. Because sericin adheres to the surface of fiber after cross-linking and solidity, the effects that the breathability of the fiber is improved and the wood is friendlier to the skin are achieved. The softened wood is better in plasticity, and dried and solidified workpieces are high in strength, resistant to bacteria, friendly to the skin and not prone to discoloring and ageing. Therefore, compared with a traditional treatment method, the antimicrobial wood softener containing the nanometer titanium dioxide is more efficient, and the additional use value of the wood is improved.

Owner:FUNAN COUNTY TIANYI CRAFTS

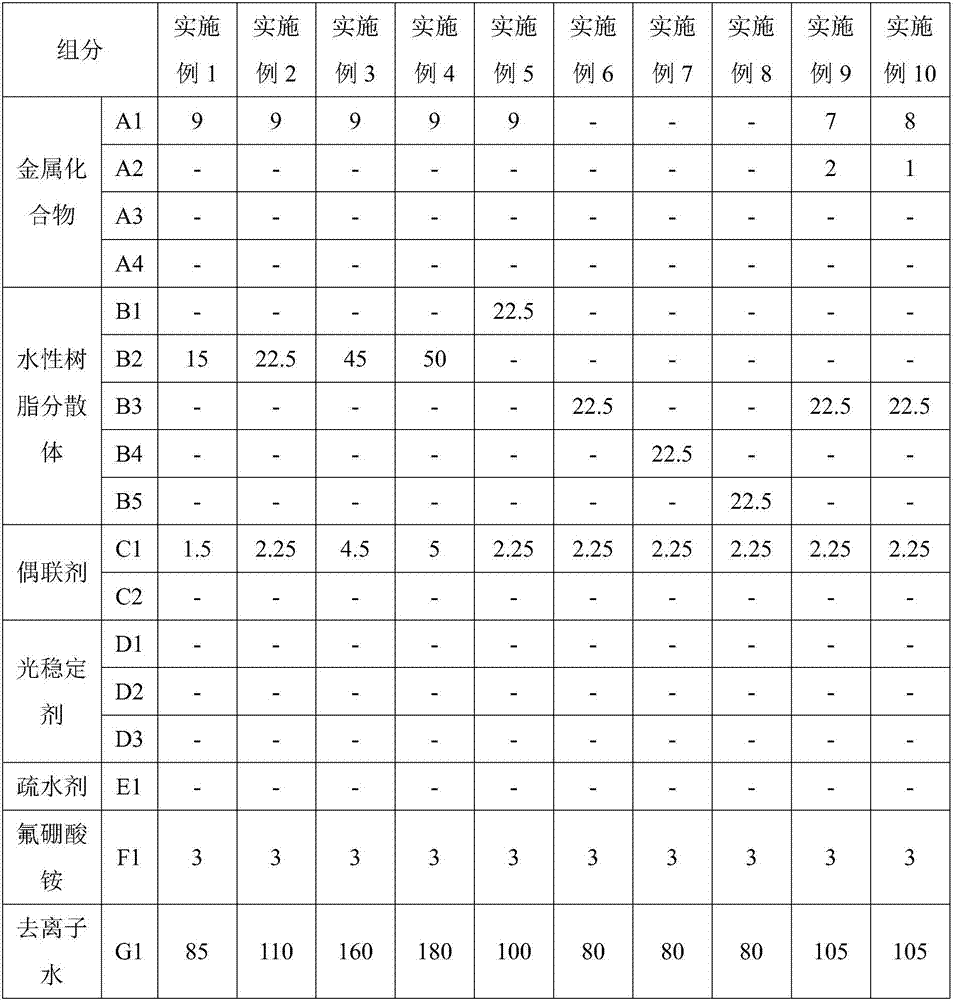

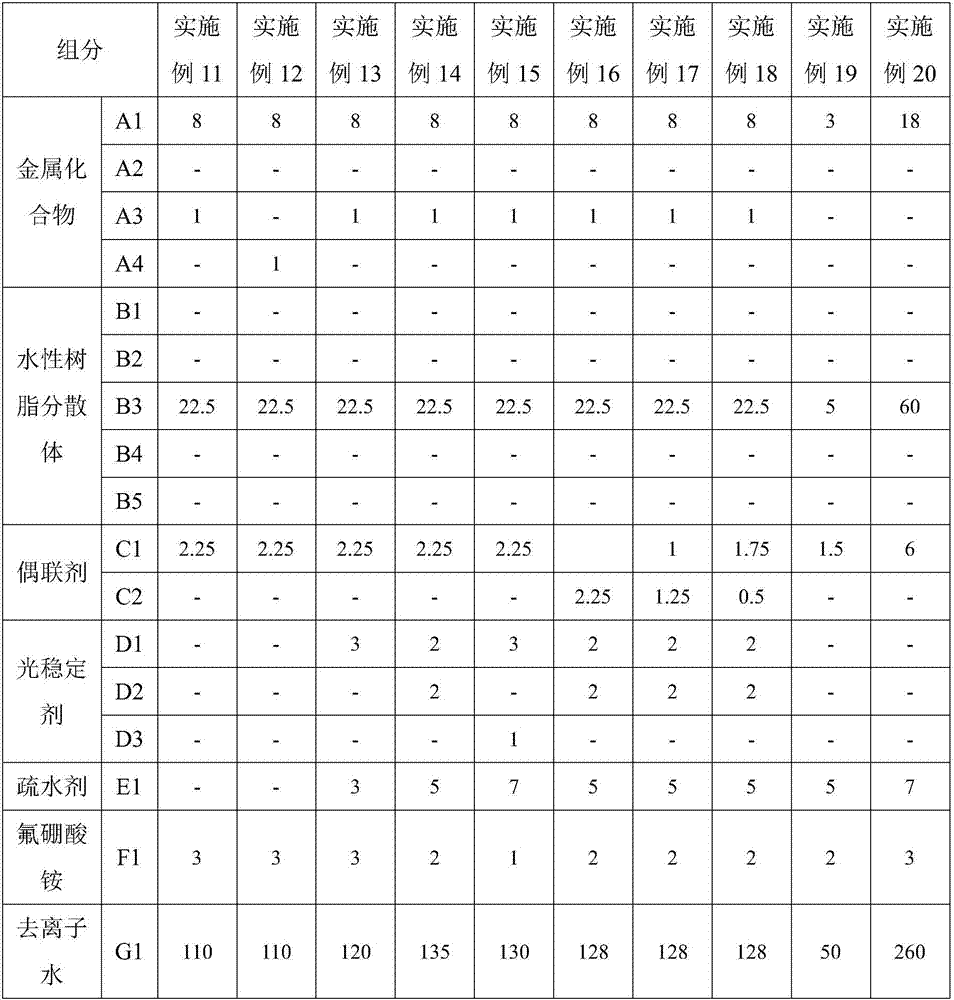

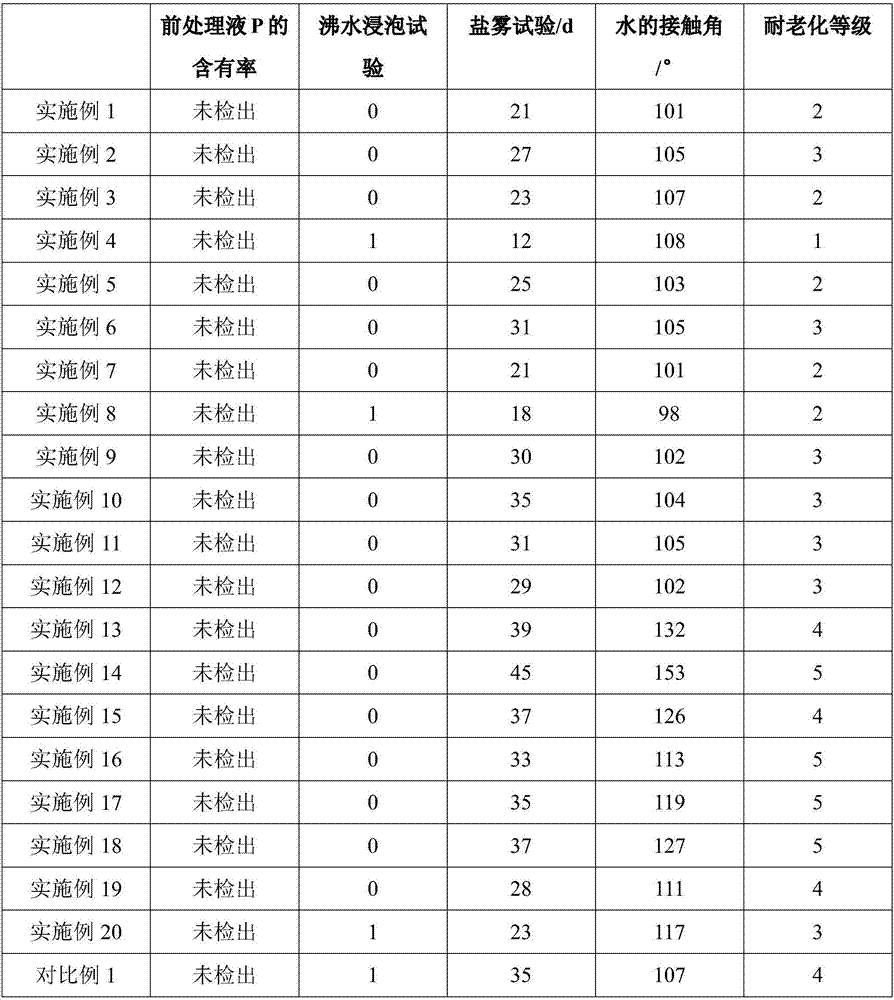

Phosphorus-free environmental-friendly metal surface pretreatment liquid and utilization method thereof

InactiveCN107099791AImprove weather resistance and aging resistanceImprove hydrophobicityMetallic material coating processesSteel platesMicro nano

The invention relates to phosphorus-free environmental-friendly metal surface pretreatment liquid and a utilization method thereof. The phosphorus-free environmental-friendly metal surface pretreatment liquid is prepared from, by weight, 3-18 parts of a metal compound, 5-60 parts of water-based resin dispersion, 1.5-6 parts of a coupling agent, 0-5 parts of a light stabilizer, 0-7 parts of a water-repellent agent, 1-3 parts of ammonium fluoroborate and deionized water which accounts for 60-65% of the weight of the whole components, wherein the water-repellent agent is hydrophobic Y2O3 with a micro-nano structure. The invention also relates to application of the phosphorus-free environmental-friendly metal surface pretreatment liquid to metal surface treatment, in particular to application to metal surface treatment of galvanized steel plates, aluminum plates or copper plates.

Owner:JINGMEN TUODA TECH CO LTD

Preparation method of hydrophobic weather-resistant and aging-resistant composite fluorocarbon resin coating for tent

InactiveCN109321047AReduce photocatalytic activityBarrier contactAnti-corrosive paintsResin coatingSilicon dioxide

The invention discloses a preparation method of a hydrophobic weather-resistant and aging-resistant composite fluorocarbon resin coating for a tent. The preparation method comprises the following steps of uniformly mixing sericite powder, silicon carbide ceramic particles, titanium dioxide coated with coupling modified aluminum oxide powder and cerium oxide, and silicon dioxide nanometer fluid, soas to obtain a pigment filler; adding a thinner and an additive into fluorocarbon resin of film-forming resin, uniformly stirring by a high-speed stirring machine, adding the uniformly mixed pigmentfiller, sand grinding and stirring by a sand mold high-speed stirring machine, adding a crosslinking curing agent, continuing to sand grind and stir until fully and uniformly mixing, putting into a vacuum drying box, vacuuming and defoaming. The coating with excellent corrosion-resistant property and aging-resistant property is prepared by using the fluorocarbon resin of film-forming resin as a substrate, using the diphenylmethane diisocyanate as the crosslinking curing agent, and using the titanium dioxide coated with cerium oxide, the silicon dioxide nanometer fluid, sericite, coupling agent-modified aluminum oxide powder and silicon carbide ceramic particles as the fillers, and is used for coating the tent; the weather-resistant and aging-resistant properties of the tent are improved, and the service life is prolonged.

Owner:ANHUI YUTANG RAIN GEAR

Special material for nylon sleeve

InactiveCN103772970AImprove toughnessEasy to use in large-scale productionWeather resistanceAnti freezing

The invention discloses a special material for a nylon sleeve. The special material comprises the following components in weight ratio: 49.5-90% of nylon 6, 1-35% of an anti-freezing agent, 1-10% of enhancer, 0.1-5.0% of antiager, 0.3-1.5% of antioxidant, and 0.3-5.5% of other assistants. The special material for the nylon sleeve, provided by the invention, can tolerate the low temperature of negative 40 DEG C and still keep good toughness, is easy to scale up to industrial production, is greatly increased in rigidity, weather resistance, age resistance and wear resistance, is convenient to produce, process, and procure, and adopts domestic materials and domestic manufacturing equipment, thereby being greatly improved in competitive power.

Owner:KECHUANG POLYMER SUZHOU

Pressure sensitive adhesive for protective film and preparation method thereof

InactiveCN101798491BImprove cohesive strengthImprove weather resistance and aging resistanceEster polymer adhesivesTectorial membraneFunctional monomer

The invention discloses a pressure sensitive adhesive for a protective film and a preparation method thereof. The pressure sensitive adhesive is formed by polymerizing acrylic monomers through radicals, wherein the acrylic monomers comprise the following components in percent by weight: 30-50 percent of acrylic soft monomer, 5-20 percent of acrylic hard monomer, 0.5-2.5 percent of acrylic functional monomer, 0.5-2.5 percent of acrylic crosslinking monomer, 40-60 percent of solvent, 0.2-2.0 percent of initiating agent and 0.01-0.2 percent of chain transfer agent. The adhesive has higher initial adhesion and permanent adhesion and excellent weather-proof and aging-resisting performances and can meet the requirement of a protective film adhesive with higher strength requirement.

Owner:BEIJING COMENS NEW MATERIALS

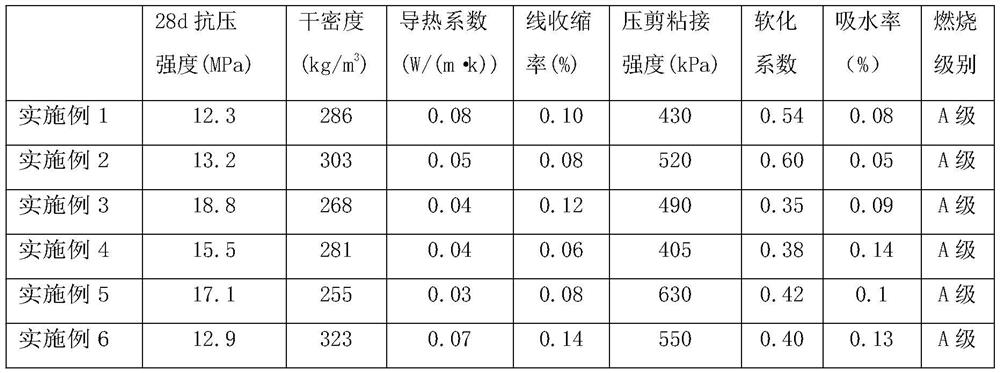

Thermal insulation mortar and preparation method thereof

ActiveCN112939553AHigh densityMutually exclusive contradiction improvementSolid waste managementThermal insulationWater repellent

The invention discloses a thermal insulation mortar and a preparation method thereof. Thethermal insulation mortar comprises 300 to 600 parts of cement, 100 to 250 parts of fine aggregate, 30 to 50 parts of fly ash, 20 to 40 parts of talcum powder, 0.5 to 2 parts of an organosilicon water repellent, 20 to 100 parts of zirconium oxide hollow spheres, 0.2 to 0.6 part of a water retention component, 5 to 10 parts of toner, 1 to 3 parts of transition metal oxide powder, 1 to 4 parts of an aerogel component, 2 to 5 parts of rubber powder and 150 to 300 parts of water. The thermal insulation mortar prepared by the invention is high in compressive strength, low in heat conductivity coefficient, low in water absorption rate and excellent in fireproof performance.

Owner:重庆中科建筑科技(集团)有限公司

A glass fiber reinforced plastic optical cable protective sleeve

ActiveCN111180149BScientific and reasonable structureEasy to useCable installations in surface ductsPlastic/resin/waxes insulatorsEpoxyPolyester

The invention discloses a glass fiber reinforced plastic optical cable protective sleeve, which includes a first glass fiber reinforced plastic tube, and the first glass fiber reinforced plastic tube is made of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin. The first polytetrafluoroethylene waterproof material layer is coated on the outer wall of the first glass fiber reinforced plastic pipe, and the outer wall of the first polytetrafluoroethylene waterproof material layer is glued with a first silicide heat insulation cotton layer. The glass fiber reinforced plastic optical cable protective sleeve passes through the cooperation between the first polytetrafluoroethylene waterproof material layer and the first silicide heat insulation cotton layer, so that the first polytetrafluoroethylene waterproof material layer and the first silicide insulation cotton layer The temperature resistance of the heat insulation cotton layer makes the first glass fiber reinforced plastic pipe have stable temperature resistance, and through the temperature resistance of the second polytetrafluoroethylene waterproof material layer and the second silicide heat insulation cotton layer, it makes The optical cables inside the first cylinder, the second cylinder and the third cylinder can work stably.

Owner:五合兴华通讯设备有限公司

A kind of production method of water-in-water multi-color paint containing colored sand

ActiveCN105925096BCost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

A kind of concrete aggregate prepared by using coal gangue and preparation method thereof

The invention relates to concrete aggregate prepared by utilizing coal gangue and a preparation method thereof. The concrete aggregate is prepared from the following raw materials in parts by weight: 110-150 parts of broken coal gangue, 50-70 parts of foundry waste sand, 10-20 parts of copper sludge, 10-20 parts of red mud, 50-70 parts of regenerated diatomite broken pieces, 5-9 parts of additives, 6-10 parts of calcium hydroxide and 5-9 parts of sodium hydroxide solution with the mass concentration of 0.5mol / L, wherein the regenerated diatomite broken pieces are prepared from the following components in parts by weight: 40-60 parts of waste diatomite slurry, 20-30 parts of modified steel slag micro-powder, 6-11 parts of a surface modifier and 0.04-0.06 part of a foaming agent; and the modified steel slag micro-powder is prepared from steel slag and sodium metaborate which accounts for 1 / 10 to 1 / 2 of the weight of the steel slag. According to the invention, a large-scale application direction is found for the coal gangue, foundry waste sand, copper sludge, red mud, steel slag and waste diatomite, the waste materials are changed into things of value, and the environmental pollution and land occupation caused by solid wastes are reduced, so that the resources are further utilized, and energy conservation and environment friendliness are achieved.

Owner:重庆交院和瑞工程检测技术有限公司

Fire-resistant sheath for novel display wire harness

InactiveCN108641264AImprove weather resistance and aging resistanceImprove scatter behaviorPoly ether ether ketoneMontmorillonite

The invention discloses a fire-resistant sheath for a novel display wire harness. The fire-resistant sheath is prepared from the following raw materials in parts by weight: 60-76 parts of AES resin, 15-30 parts of syndiotactic polypropylene, 7-15 parts of modified montmorillonite, 4.5-9 parts of zircon powder, 7-13 parts of cork powder, 2.5-6 parts of asbestos wool, 5-11 parts of calcium silicatetailings, 2-5.5 parts of carbon whiskers, 1-3.5 parts of bis(2-methoxyethyl) phthalate, 2-6.5 parts of zinc isooctanoate, 1-3 parts of poly ether ether ketone and 0.5-2 parts of glyceryl monostearate.The fire-resistant sheath has excellent fire resistance.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

A kind of high environmental protection concrete aggregate and preparation method thereof

Owner:杭州申华混凝土有限公司

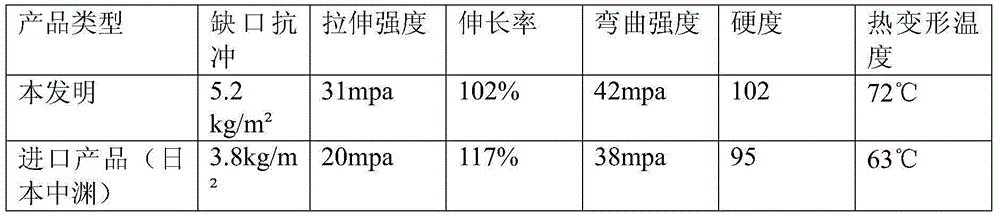

Two-color co-extrusion polymer alloy material and its preparation process

ActiveCN103571120BLow costImprove weather resistance and aging resistanceN-phenylmaleimideMethacrylate

The present invention relates to a double color co-extrusion polymer alloy material and a preparation process thereof. The double color co-extrusion polymer alloy material is prepared from the following raw materials, by weight: 100 parts of an acrylate rubber grafted styrene-methacrylate-N-phenylmaleimide copolymer resin, 2-5 parts of a plasticizer, 3-5 parts of an antioxidant, 2.5 parts of a lubricant, 0.1-1 part of an ultraviolet absorber, and 0.5-2 parts of a pigment. According to the present invention, the acrylate rubber grafted styrene-methacrylate-N-phenylmaleimide copolymer resin is selected as the base material, and a plurality of auxiliary agents, the rational formula scheme and the rational preparation process are matched to produce the plastic alloy so as to replace the imported product, such that the cost is reduced, weathering resistance and aging resistance of the plastic alloy are better than weathering resistance and aging resistance of the imported product, and applicability is good, wherein the quality and the appearance of the plastic alloy achieve the similar foreign products, and the plastic alloy is suitable for double color double extrusion.

Owner:HANGZHOU HUACHUANG IND

Nanometer bi-layer film biogas digester material and preparation method thereof

ActiveCN102558713BGood physical and mechanical propertiesGood weather resistancePolymer scienceAntioxidant

The invention discloses a nanometer bi-layer film biogas digester material, which is composed of the following components: PVC (polyvinyl chloride) resin, DOP (Dioctyl-Phthalate), DBP (dibutyl phthalate), a stabilizing agent, an antioxidant, an anti-UV (ultraviolet) agent, nano calcium carbonate, modified red mud and other accessory ingredients, wherein the components are subjected to the calendering technology, the fitting technology and the surface treatment technology, and two groups of single-surface surface-treated single-layer biogas digester materials are combined to obtain the bi-layer biogas digester material. The nanometer bi-layer film biogas digester material has the advantages that nano calcium carbonate and the modified red mud are adopted to serve as filling agents, thus the weather resistance, the aging resistance and the like of a PVC film are improved and the service life of the bi-layer film biogas digester material is prolonged; the acrylate coating is used for surface treatment, thus the weather resistance and the aging resistance of the bi-layer film biogas digester material are improved; and because of adopting the bi-layer film structure, the inner-layer film has excellent air impermeability and chemical corrosion resistance, and the outer-layer film has good physical and mechanical property and aging resistance so as to prevent the inner-layer film from being damaged by the external environment.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Chromium-free fingerprint-resistant environment-friendly coating and preparation method thereof

InactiveCN112745768AReduce investmentSimple manufacturing methodPolyurea/polyurethane coatingsEnd-groupPolyethylene glycol

The invention discloses a chromium-free fingerprint-resistant environment-friendly coating and a preparation method thereof. The chromium-free fingerprint-resistant environment-friendly coating is prepared from the following components in parts by weight: 45 to 60 parts of Lanbda-cyhalothric acid modified hyperbranched poly (urethane-amine) with a hydroxyl group as an end group and with a vinyl group in an internal branched unit, 10 to 15 parts of a functional film-forming polymer, 0.5 to 1.5 parts of a water-soluble initiator, 5 to 8 parts of a hydroxyl-terminated hyperbranched nano-hybrid polymer HB-SiO2, 0.3 to 0.5 part of a wetting agent, 0 to 4 parts of a cosolvent, 1 to 2 parts of a de-foaming agent and 30 to 40 parts of water, the functional film-forming polymer is a copolymer which is generated by carrying out a copolymerization reaction on benzotriazole-1-carboxythioacid allyl amide, N-(4-cyano-3-trifluoromethylphenyl) methacrylamide, polyethylene glycol monoallyl ether and glycidyl methacrylate. The invention also provides a preparation method of the chromium-free fingerprint-resistant environment-friendly coating. The chromium-free fingerprint-resistant environment-friendly coating provided by the invention is remarkable in fingerprint-resistant effect, good in comprehensive performance and performance stability, good in environmental protection property and corrosion resistance and strong in adhesive force with a base material.

Owner:泗县钧科新材料科技有限公司

Luminescent material and preparation method and application thereof

ActiveCN102807866BGood weather resistanceStrong persistenceLuminescent compositionsPolymer scienceElectrocommunication

The invention belongs to the technical field of modifying and processing technology for macromolecule, and relates to a luminescent material and a preparation method and application thereof. The luminescent material includes the following components based on weight proportion: 90-100 portions of aluminium oxide, 80-95 portions of calcium carbonate, 8-20 portions of boric acid, 1.5-5 portions of europium oxide, 2-4 portions of terbium oxide. Compared with the prior art, master batches of weather-resistant energy-storage luminescent polyethylene plastic prepared from the luminescent material of the invention have excellent weather-resistant performance and durability, environment-friendly degradation products, longer luminescence time and zero radioactivity. The master batches of the luminescent material are widely used in architectural ornament, transportation, fire protection, electrocommunication, subway tunnels, advertising boards and other plastic products.

Owner:江苏融威实业有限公司

High stability concrete silicone joint glue and preparation method thereof

ActiveCN105131899BHigh activityHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesNitrile rubberPlasticizer

The invention discloses a high-stability concrete silicone joint glue and a preparation method thereof. The joint glue consists of 100 parts by mass of α,ω-dihydroxy polydimethylsiloxane, 50-150 parts of filler 0.5-10 parts of thixotropic agent, 0.5-10 parts of chain extender, 5-15 parts of curing agent, 0.1-5 parts of tackifier, 0.01-3 parts of catalyst, 1-10 parts of liquid nitrile rubber, First, α, ω-dihydroxy polydimethylsiloxane, thixotropic agent and filler are made into a base material in a kneader, and then the base material is transferred into a high-speed disperser, and the remaining raw materials are added to react to obtain the base material. seam glue. The invention uses liquid nitrile rubber modified silicone joint adhesive, and adopts a specific chain extender to endow the joint adhesive with permanent toughness and mechanical property retention, and the plasticizer does not migrate, does not damage the bonding, and greatly improves Improve the bonding strength, excellent aging resistance, environmental protection and pollution-free.

Owner:CHENGDU GUIBAO SCI & TECH

Rope coating layer and preparation process thereof

InactiveCN107385924ACompatibility is reasonableRigorous workmanshipFibre treatmentTrimethylolpropanePolytetrafluoroethylene

The invention discloses a rope coating layer in the technical field of coating layers. The rope coating layer contains the following components in percentage by mass: 5%-20% of polyether 210, 3%-5% of isocyanate, 0-1% of dimethylolpropionic acid, 0-0.5% of trimethylolpropane, 0-2% of triethylamine, 1%-6% of acetone, 0-5% of an emulsifying agent, 5%-15% of butyl acrylate, 5%-10% of methyl acrylate, 0-3% of acrylic acid, 0-5% of methyl methacrylate, 10%-15% of a polytetrafluoroethylene emulsion, 5%-10% of an initiator and the balance of water. The rope coating layer has the beneficial effects that the formula compatibility is reasonable, and the process is rigorous; the performance of the product is improved, the rope coating layer is high in adhesive force, large in cohesion and stable in performance and has wear resistance, weather resistance, aging resistance and corrosion resistance, and the service life of a rope is greatly prolonged.

Owner:江苏兴龙光电发展有限公司

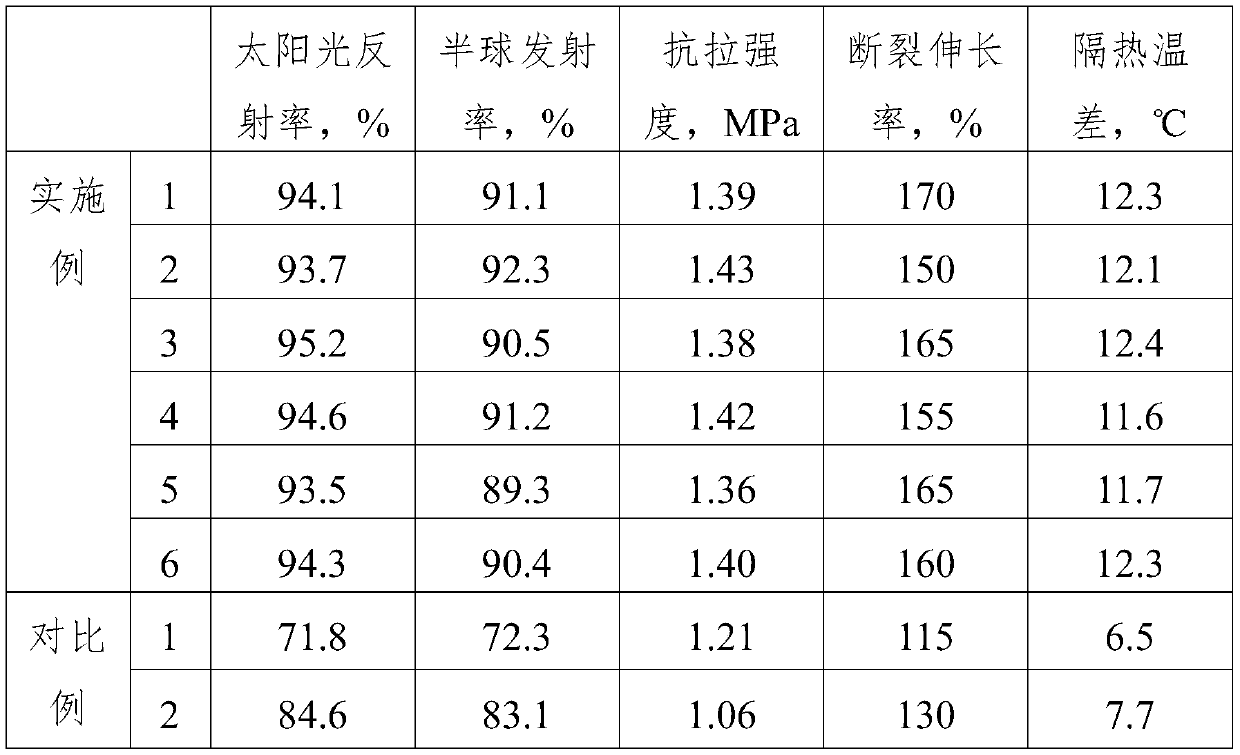

Reflective heat-insulation exterior wall coating and preparation method thereof

InactiveCN111154358AImprove performanceGood synergyRosin coatingsReflecting/signal paintsFiberWeather resistance

The invention provides a reflective heat-insulation exterior wall coating and a preparation method thereof. The reflective heat-insulation exterior wall coating comprises, by mass, 9-15% of ceramic wastes, 10-13% of nanometer titanium dioxide, 3-7% of prefabricated fiber particles, 25-35% of a functional filler, 7-10% of a coating assistant, and the balance of a composite emulsion. Reasonable rawmaterial selection and prefabrication are carried out, so the performance exertion of the material is obviously improved, the synergistic effect is good, the heat dissipation conductivity is excellent, the reflectivity to sunlight is as high as 95%, the applicable wavelength range of reflection and radiation is wide, and the overall weather resistance and aging resistance are remarkably improved;and additionally, the coating is uniform and compact, the cross-linking reaction combination, the adhesive force and the stability between molecular structures are improved, the mechanical propertiesof the coating are greatly improved, the quality of the coating is good, the service life is effectively prolonged, and the cost performance is high.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com